Process and device for preparing propylene by dehydrogenating propane or propane-enriched light hydrocarbon

A technology for low-carbon hydrocarbons and propane, which is applied in the field of dehydrogenation of low-carbon alkanes, can solve the problems of undeveloped and protected heat-carrying functions, unfavorable catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

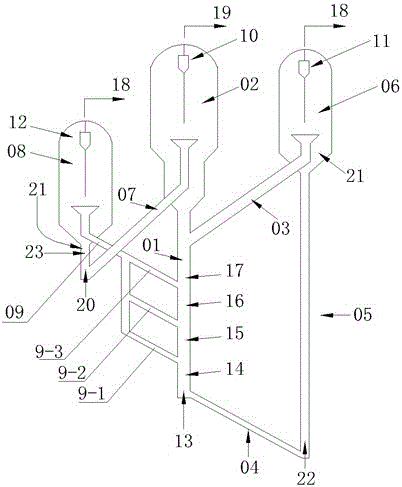

[0050] Such as figure 1 As shown, a propane or propane-rich low-carbon hydrocarbon dehydrogenation propylene device of the present invention includes a riser reaction system, a catalyst circulation regeneration system, and a heat carrier circulation system, wherein:

[0051] The riser reaction system includes a riser reactor 01, the lower part of the riser reactor 01 is the raw material inlet, and the upper part of the riser reactor 01 is the catalyst inlet, and the riser reactor 01 is sequentially arranged into several reaction sections from bottom to top. Each reaction section is correspondingly provided with a heat transfer pipe for supplementing heat for the reaction; the reaction settler 02 is arranged above the riser reactor 01, and the reaction settler 02 is provided with an oil-gas cyclone separator 10;

[0052] The catalyst circulation regeneration system includes the first regenerator 06 for catalyst regeneration. One end of the first regenerator 06 is the input end ...

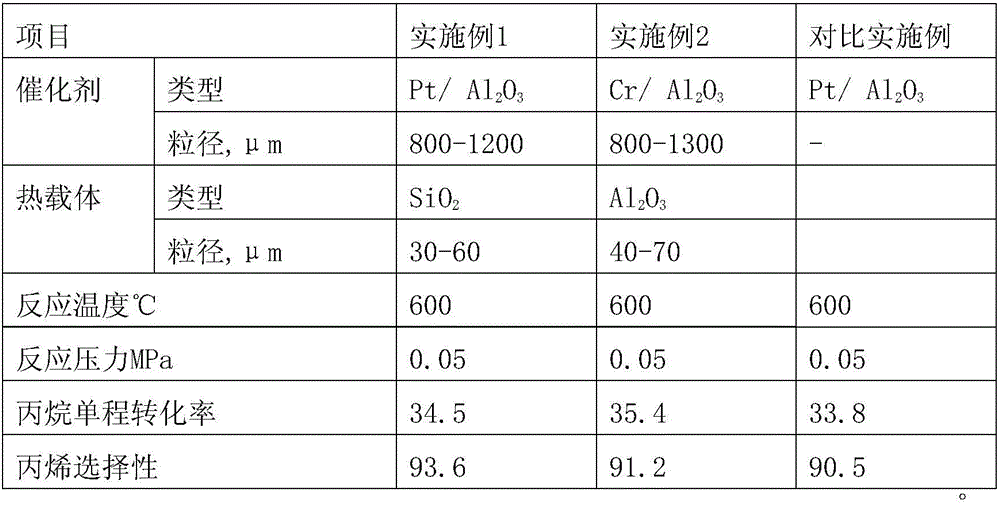

Embodiment 2

[0065] The process equipment is the same as in Example 1, except that the catalyst, heat carrier and process parameters are as shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com