Water-based color paste and preparation method thereof as well as robot

A water-based color paste and white pigment technology, applied in the field of pigments, can solve the problems of easy decolorization and peeling of pigment coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

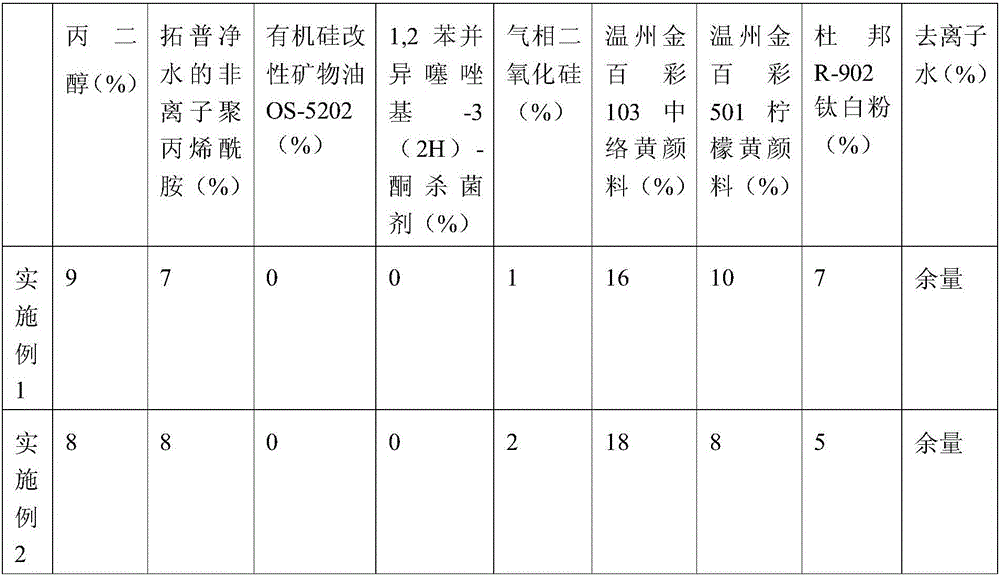

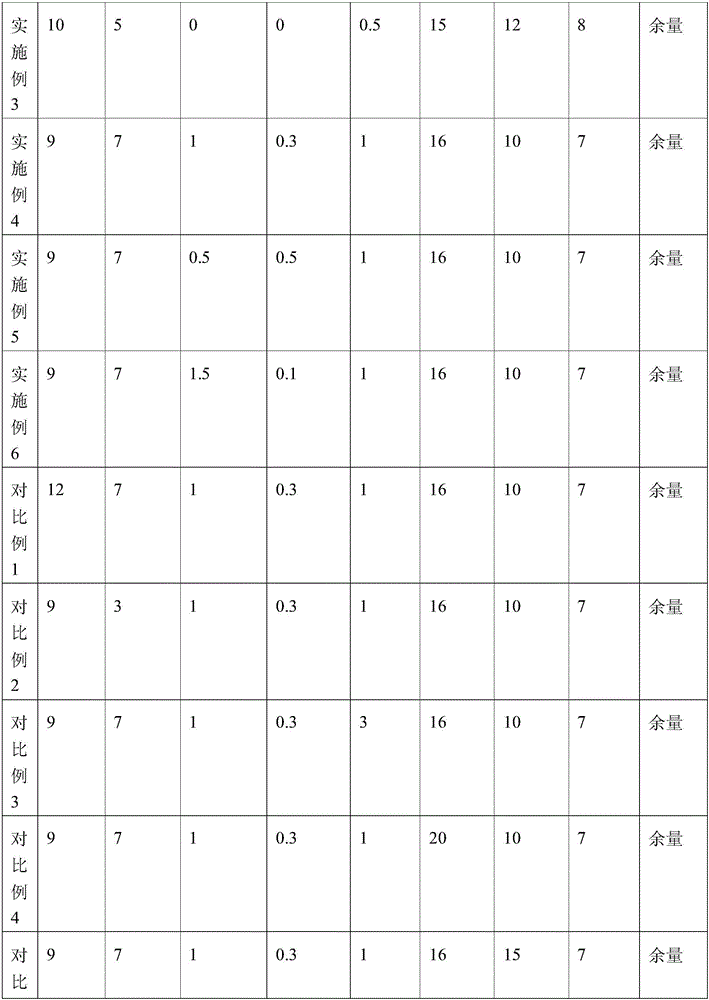

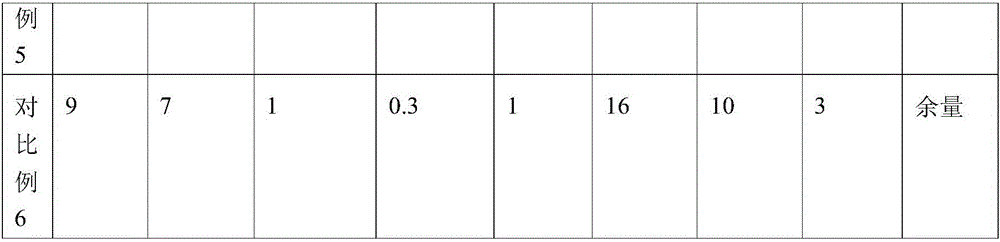

Examples

preparation example Construction

[0020] In another typical embodiment of the present application, a method for preparing the above-mentioned water-based color paste is provided, the preparation method comprising: mixing an antifreeze hydrophilic agent with a wetting and dispersing agent to form a first mixture; mixing the first mixture Mix with water to obtain a second mixture; the second mixture is mixed with an optional defoamer, an optional bactericide and an anti-settling agent in turn to obtain a third mixture; mesophyll yellow pigment, tartrazine pigment, white pigment Mix with the third mixture to obtain a premix; grind the premix to fineness≤30μm, ΔE≤0.8, and relative tinting strength%=100±5 to obtain a water-based color paste. First antifreeze hydrophilic agent and wetting dispersant are mixed, can be beneficial to the performance of antifreeze hydrophilic agent; Then mix with defoamer, bactericide and anti-sedimentation agent successively and can make each material disperse evenly as far as possible;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com