Weft detection device for looms

A detection device and weft yarn technology, which is applied in the inspection of textile materials, auxiliary equipment for weaving, textiles, etc., can solve the problems of weft yarn arrival time deviation, weft yarn breakage, weft yarn front end jumping back, etc., and achieve the effect of preventing detection delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

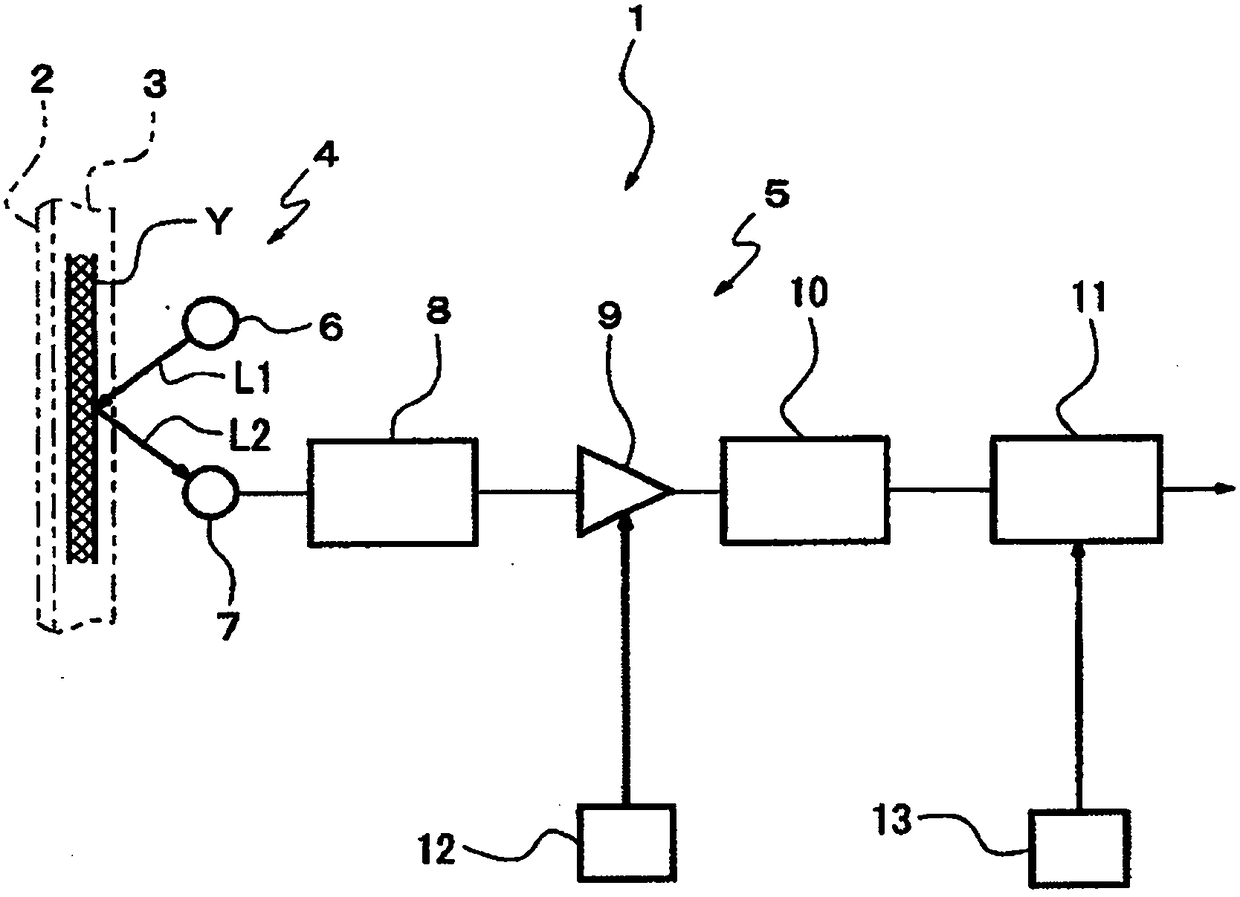

[0027] based on Figure 1 ~ Figure 3 Embodiments of the present invention will be described. figure 1 A weft yarn detecting device 1 used in an air jet loom using multicolored weft yarns of two or more colors is shown. In addition, the weft yarn detecting device 1 described in this specification for detecting multi-color weft yarns is not limited to the case of being installed on a multi-color loom, but also includes the case of being installed on a loom that inserts weft yarns of one color.

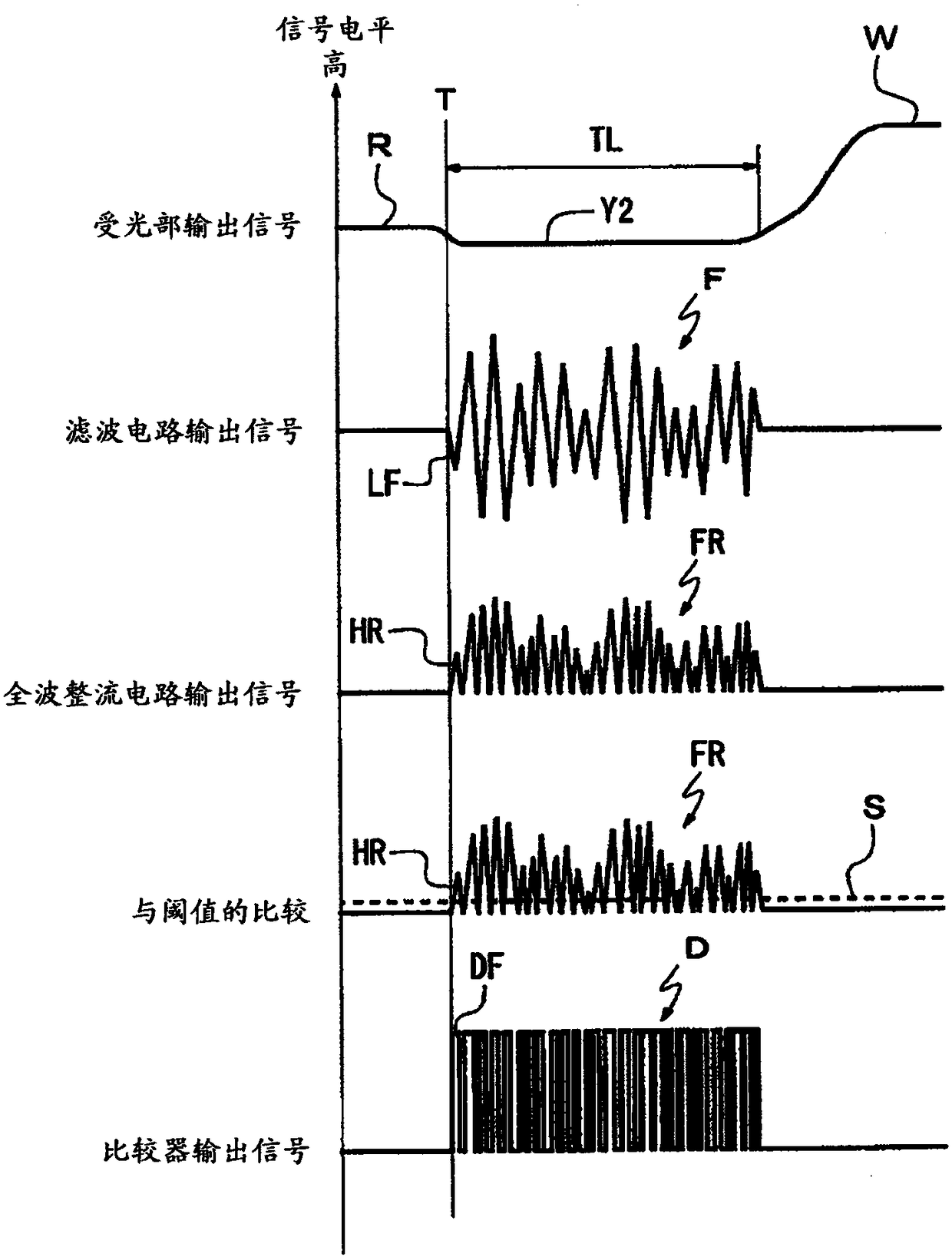

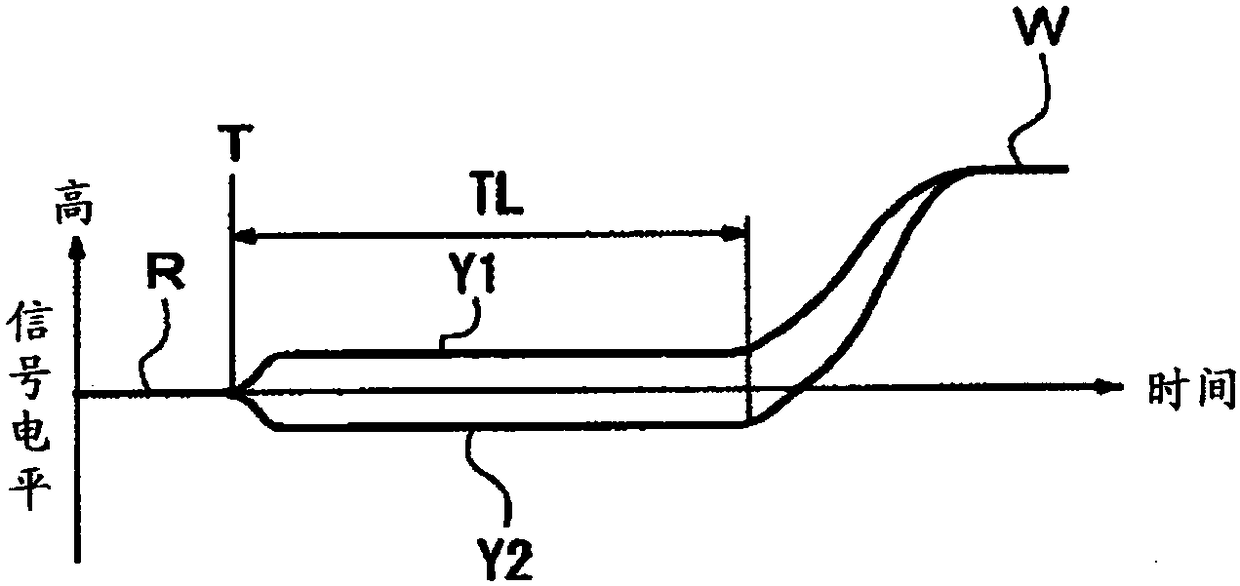

[0028] exist figure 1 Among them, the weft guide path 3 of the deformed reed 2 provided in the sley (not shown) constitutes a path through which the weft yarn Y to be weft-inserted passes. The weft detection device 1 includes a reflective photoelectric sensor 4 and a signal processing circuit 5 as a signal processing means. The photoelectric sensor 4 is composed of a light projecting part 6 and a light receiving part 7, wherein the light projecting part 6 is composed of a light emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com