A kind of environment-friendly painting equipment

An environment-friendly, painting technology, applied in the field of machinery, can solve the problems of small storage chamber, poor sealing, complex structure, etc., and achieve the effect of convenient use, convenient carrying, and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

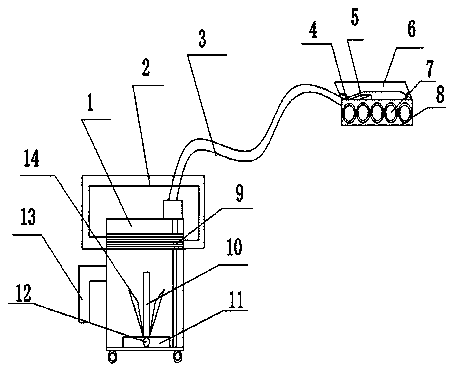

[0012] refer to figure 1 The shown environment-friendly painting equipment includes a storage chamber 1, a spraying part 8 and a spray pipe 3; the spray pipe 3 is connected to the storage chamber 1; the interior of the storage chamber 1 is set There is a stirring device; the stirring blade 14 is arranged in the stirring device; the heating rod 10 is arranged in the middle of the stirring blade 14; the five spraying heads 7 are arranged on the spraying part 8; the spraying head 7 is provided with a scraper 6; the angle adjustment valve 4 is arranged on the scraper 6; a booster 5 is arranged between the spray part 8 and the spray pipe 3; the storage chamber 1 A threaded sealing cover 9 is arranged on the top; an insertion port 13 is arranged on the surface of the storage cavity 1 .

[0013] As a preferred technical solution, a rotating disk 11 is provided below the stirring blade 14 .

[0014] As a preferred technical solution, the rotating disk 11 is provided with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com