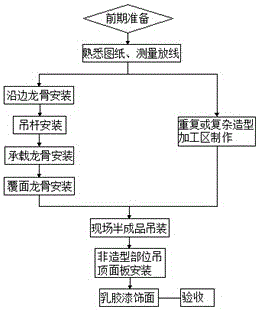

Construction process for repeated modeling ceiling

A ceiling and process technology, applied in the direction of building structure, construction, etc., can solve the problems of large amount of cross-work on-site ceiling, many shapes of the same specification, and low construction efficiency on site, so as to reduce the amount of cross-work, high construction efficiency, The effect of high construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0035] see figure 1 , the embodiment of the present invention includes:

[0036] The construction process of a repetitive modeling suspended ceiling mainly includes the following steps:

[0037] 1. Measurement and setting out:

[0038] 1) According to the construction drawings, measure and set out the construction site to determine the +1.000 elevation line and the lowest elevation line of the suspended ceiling;

[0039] 2) Determine the position of each shape;

[0040] 2. Installation along the side keel: install the side keel along the wall;

[0041] 3. Boom installation:

[0042] 1) Mark the hanging point position of the boom according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com