Column type lifting water drill

A column-type, water-drilling technology, used in drilling tools, drilling equipment, earth-moving drilling, etc., can solve the problems of high risk, poor ability to adapt to terrain, and easy damage to drill bits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

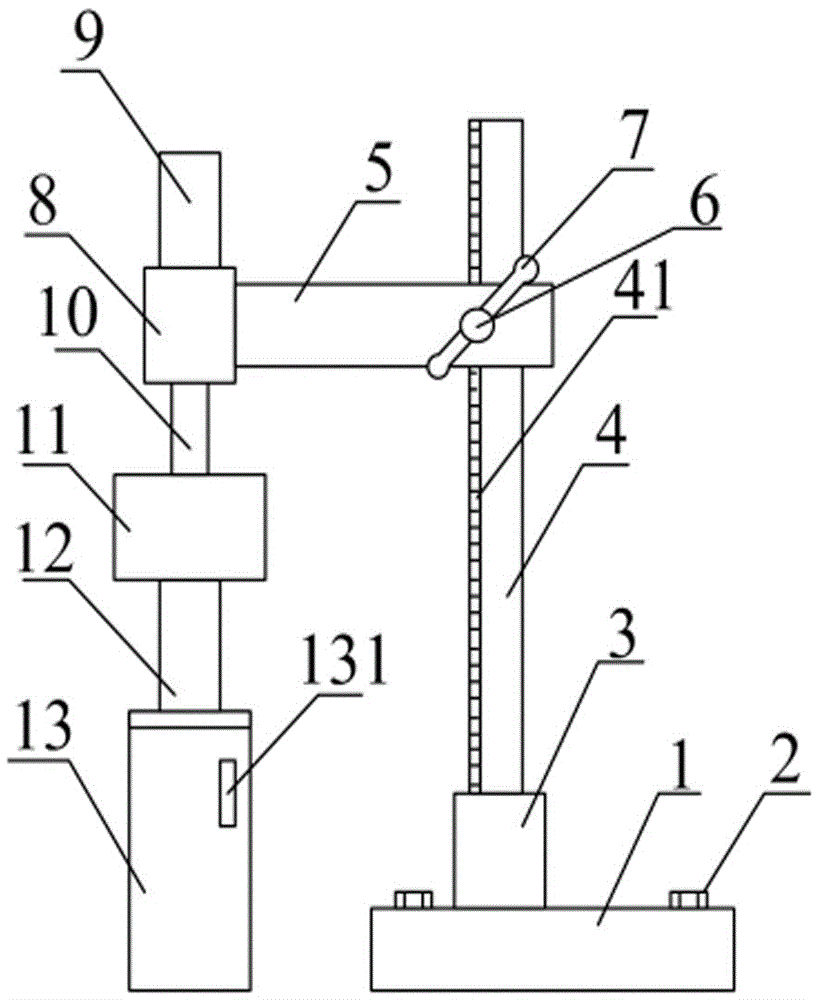

[0023] as attached figure 1 And attached figure 2 shown

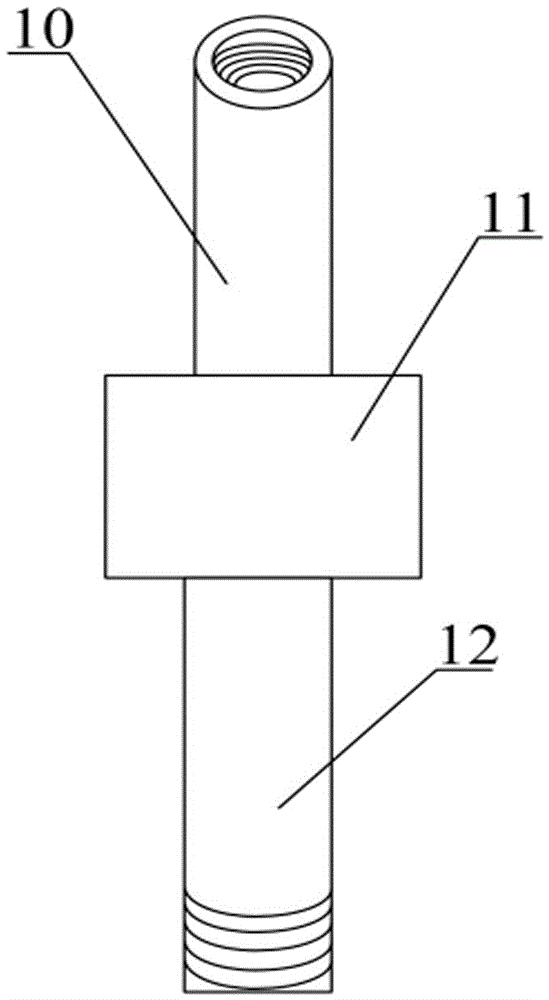

[0024] The invention provides a column-type lifting water drill, including a base 1, a fixing bolt 2, a mounting groove 3, a column 4, a connecting part 5, a lifting gear 6, an adjusting handle 7, a fixing clip 8, a motor 9, a first connecting shaft 10, and an oscillation deceleration machine 11, the second connecting shaft 12 and the drill bit 13, the base 1 is fixed by the fixing bolt 2; the installation groove 3 is welded on the upper surface of the base 1 and the column 4 is inserted in the upper part; the connecting part 5 is passed through The internal lifting gear 6 is connected to the column 4 at one end, and the other end is connected to the fixed clip 8; the motor 9 is arranged on the top of the fixed clip 8 and connected to the first connecting shaft 10; the vibration The reducer 11 connects the first connecting shaft 10 and the second connecting shaft 12; the second connecting shaft 12 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com