Tower tube pouring construction method and tower tube

A construction method and tower tube technology, applied in the field of construction, can solve the problems of high construction costs, achieve low cost, ensure stability, and reduce the risk of internal mold instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

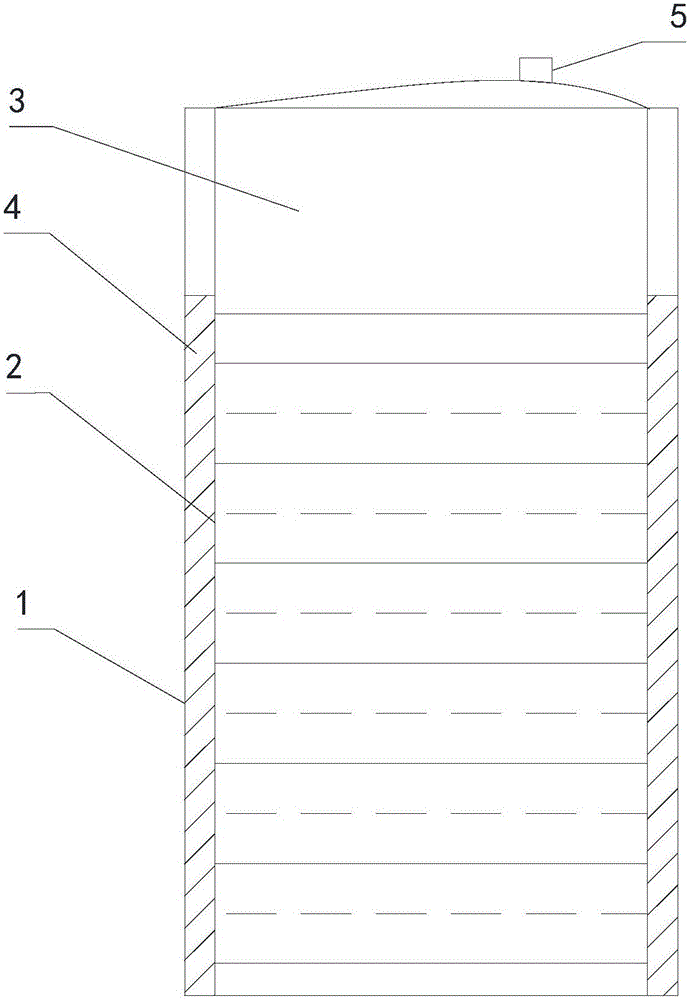

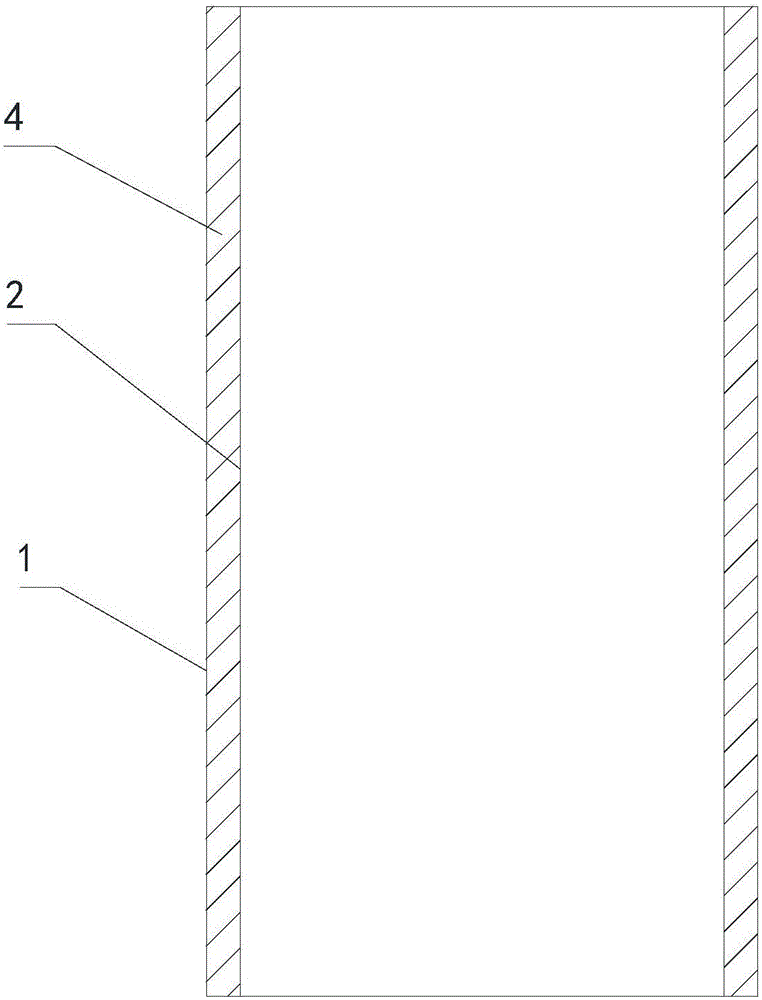

[0037] see figure 1 - image 3 as shown, figure 1 It is a schematic diagram of the structure of the outer mold and inner mold before the tower is poured, and no airtight cabin is placed; figure 2 It is a schematic diagram of the structure of the outer mold and the inner mold during the pouring process of the tower. In the figure, a sealed cabin has been placed inside the inner mold, and the tower is in a state of pouring a part. The fluid in the sealed cabin is basically the same height as the poured concrete; image 3 Schematic diagram of the outer formwork and inner formwork completed for the pouring of the tower, the airtight cabin has been removed. in figure 2 , image 3 The sloped hatch of is shown as a concreted tower.

[0038] see figure 1 - image 3 As shown, the tower pouring construction method provided in this embodiment includes:

[0039] Step 100, respectively setting an outer mold 1 and an inner mold 2 on both sides of the tower to be poured. It should...

Embodiment 2

[0067] In order to save space, the improved features of this embodiment are also reflected in figure 1 - image 3 in, therefore, combined with figure 1 - image 3 The configuration of this example will be described.

[0068] This embodiment provides a tower tube. This embodiment adopts the tower tube pouring construction method described in Embodiment 1, and the sealed cabin 3 that is arranged inside the inner mold 2 and can expand and contract makes it It can effectively reduce the risk of instability of the inner formwork 2, and has the advantages of convenient construction and low pouring construction cost.

[0069] Optionally, the tower 4 includes a poured concrete structure, and may also include an outer form 1 and / or an inner form 2 to improve the tensile performance of the tower 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com