Centrifugal blades, fan systems and air conditioning units

A centrifugal fan and blade technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. , to solve the effect of excessive noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

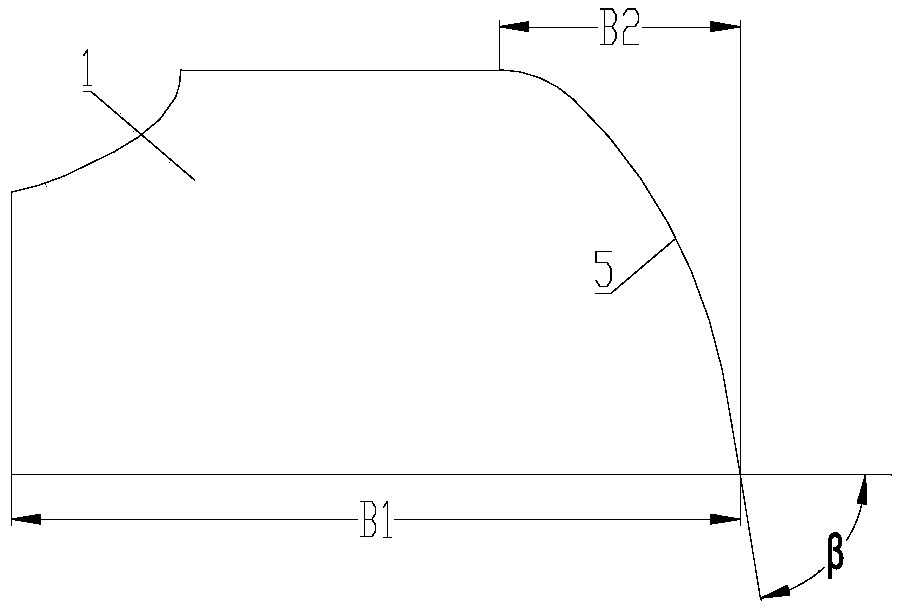

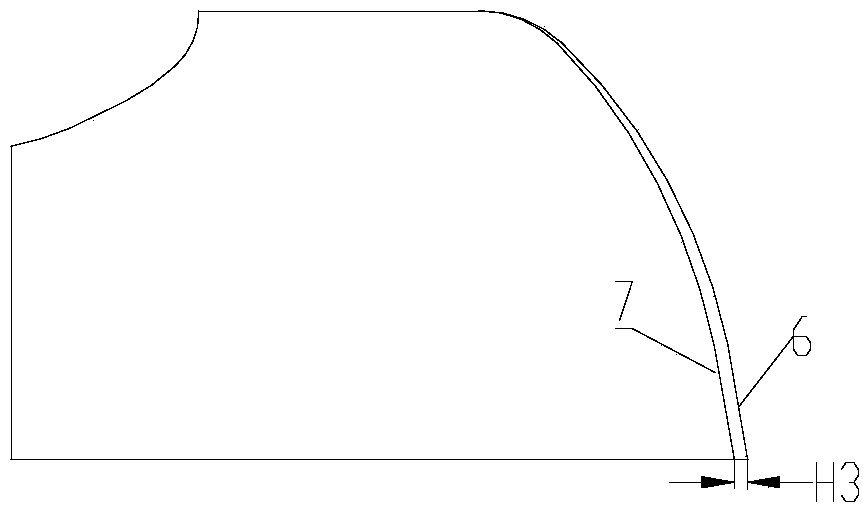

[0026] The inventor carried out aerodynamic simulation calculations on the fan blades, and found that the structure at the leading edge of the blade is pointed, and it is easy to generate large broadband noise after being impacted by high-speed airflow, that is, the maximum value of broadband noise is at the leading edge. Therefore, The invention improves the design of the leading edge of the blade to reduce noise.

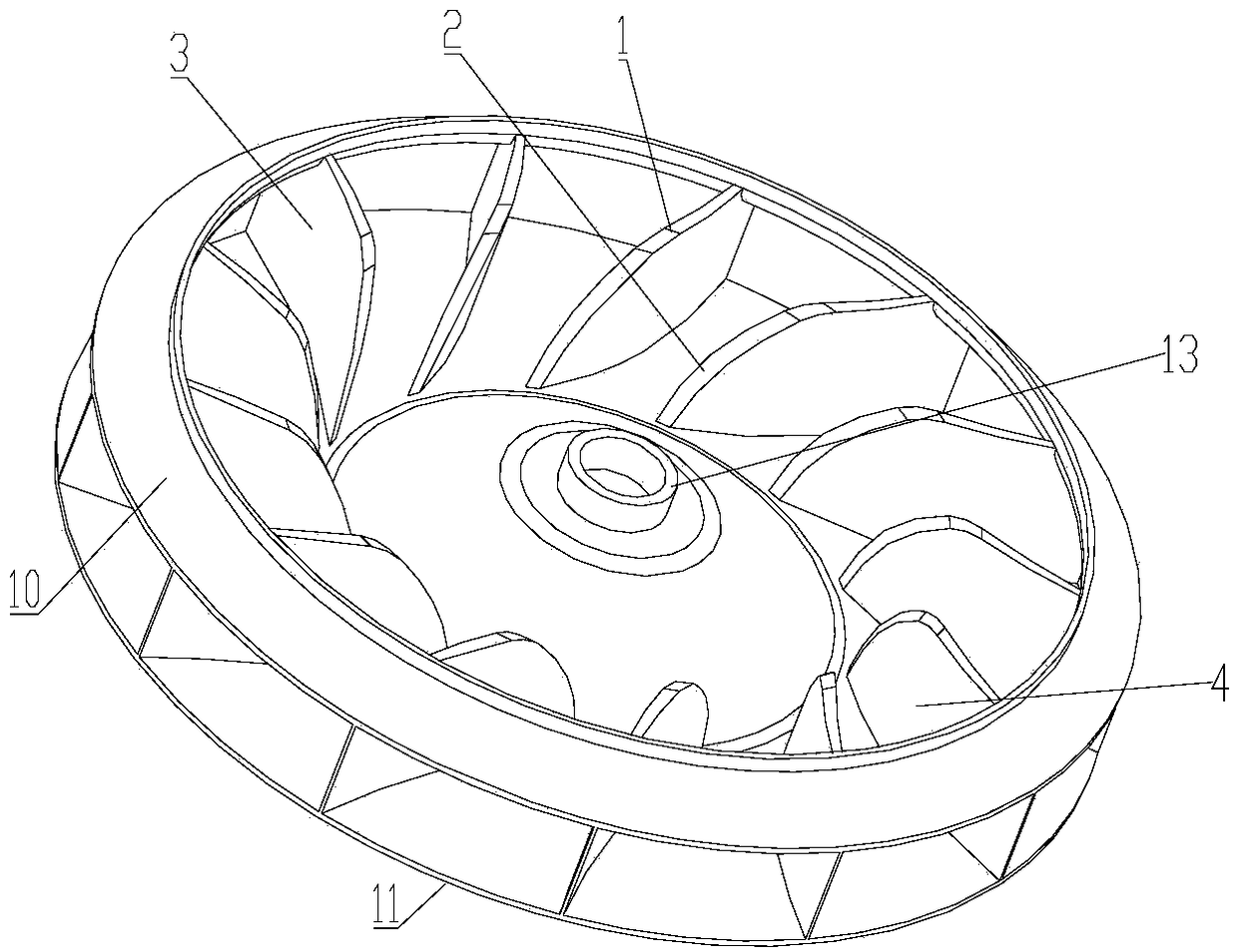

[0027] Please refer to Figure 1 to Figure 5 , the centrifugal fan blade in the present invention includes a blade 1 , a front disc 10 and a rear disc 11 . Wherein, one side of blade 1 is connected with front disk 10, and the projection of front disk 10 on its meridian plane is arc-shaped; the other side of blade 1 is connected with rear disk 11, that is, blade 1 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com