Efficient construction mode based on construction site

A construction method and construction technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of increasing the difficulty of taking steel bars, inconvenient picking of steel bars, and residual dust on the surface of steel bars, etc. , to achieve the effect of reducing cutting difficulty, reducing heat, and facilitating cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

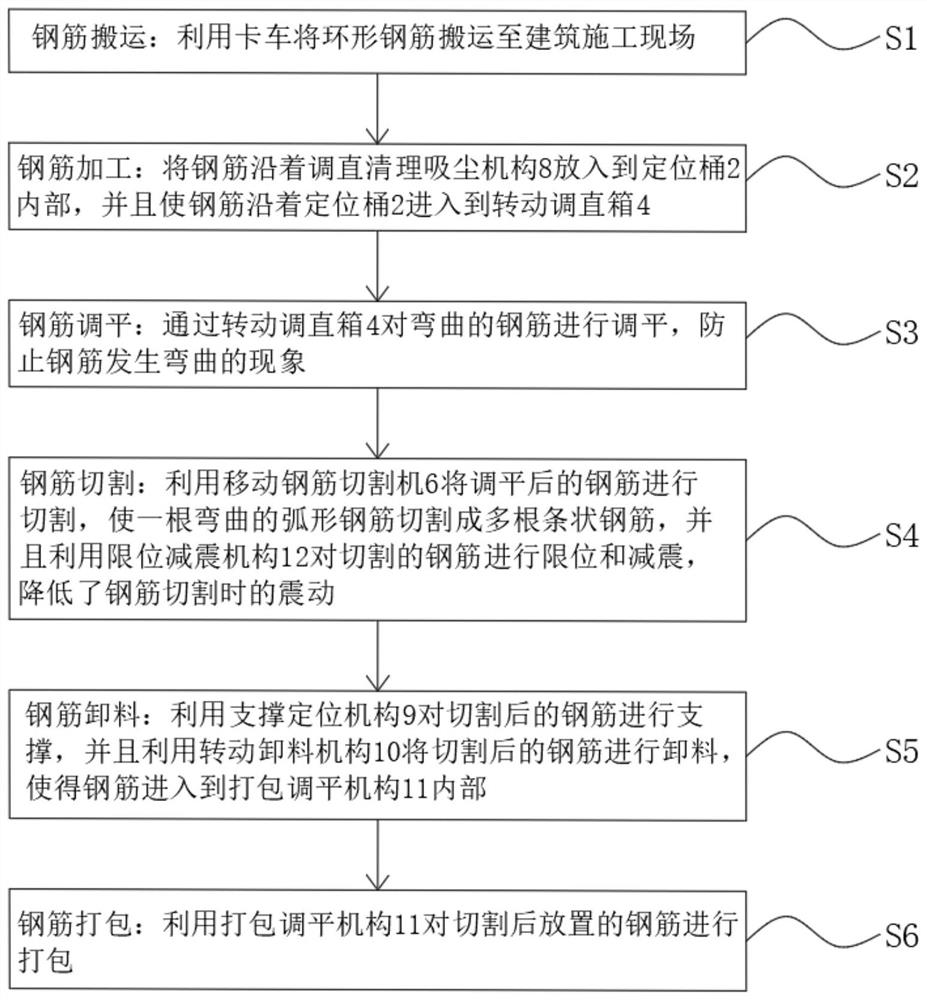

[0066] Example: such as figure 1 As shown, the present invention provides a technical solution, S1; steel bar handling: utilize trucks to transport ring-shaped steel bars to the construction site;

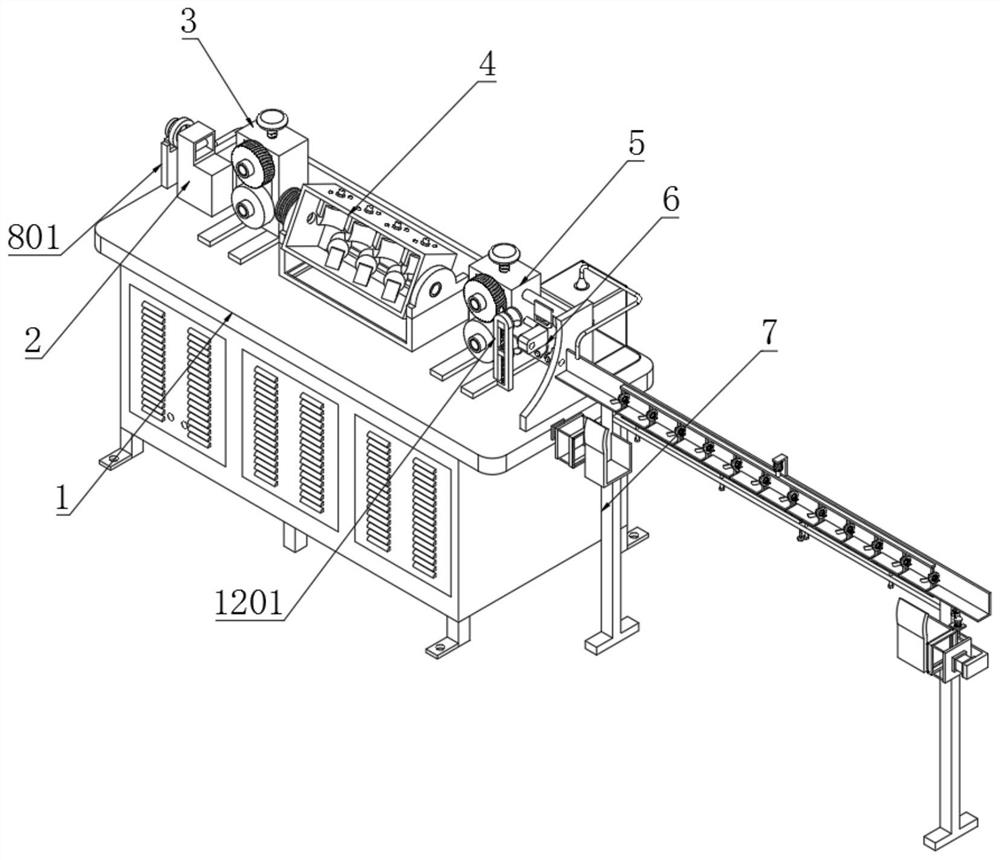

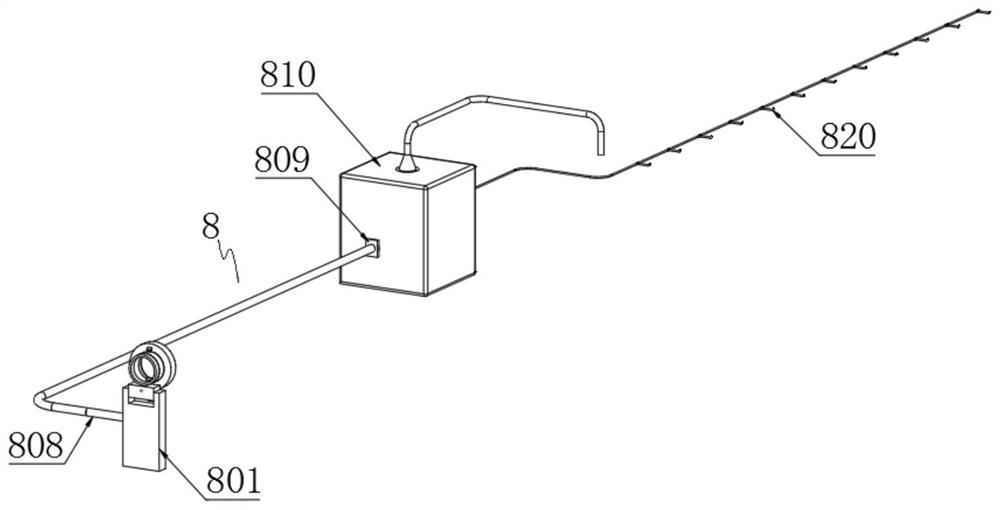

[0067] S2: steel bar processing: put the steel bar into the positioning bucket 2 along the straightening and cleaning dust suction mechanism 8, and make the steel bar enter the rotating straightening box 4 along the positioning bucket 2;

[0068] S3; steel bar leveling: leveling the bent steel bar by rotating the straightening box 4 to prevent the steel bar from bending;

[0069] S4; steel bar cutting: Utilize mobile steel bar cutting machine 6 to cut the leveled steel bar, so that a curved arc steel bar is cut into a plurality of bar-shaped steel bars, and utilize the limit shock absorbing mechanism 12 to limit the cut steel bar Position and shock absorption, reducing the vibration when cutting steel bars;

[0070] S5: Steel bar unloading: use the support positioning mechanism 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com