Dotting and feeding component for PCB (Printed Circuit Board) dotting device

A kind of PCB circuit board, circuit board technology, applied in the direction of assembling printed circuit with electrical components, etc., can solve the problems of automatic feeding of solder, poor dotting effect, inconvenient dotting, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

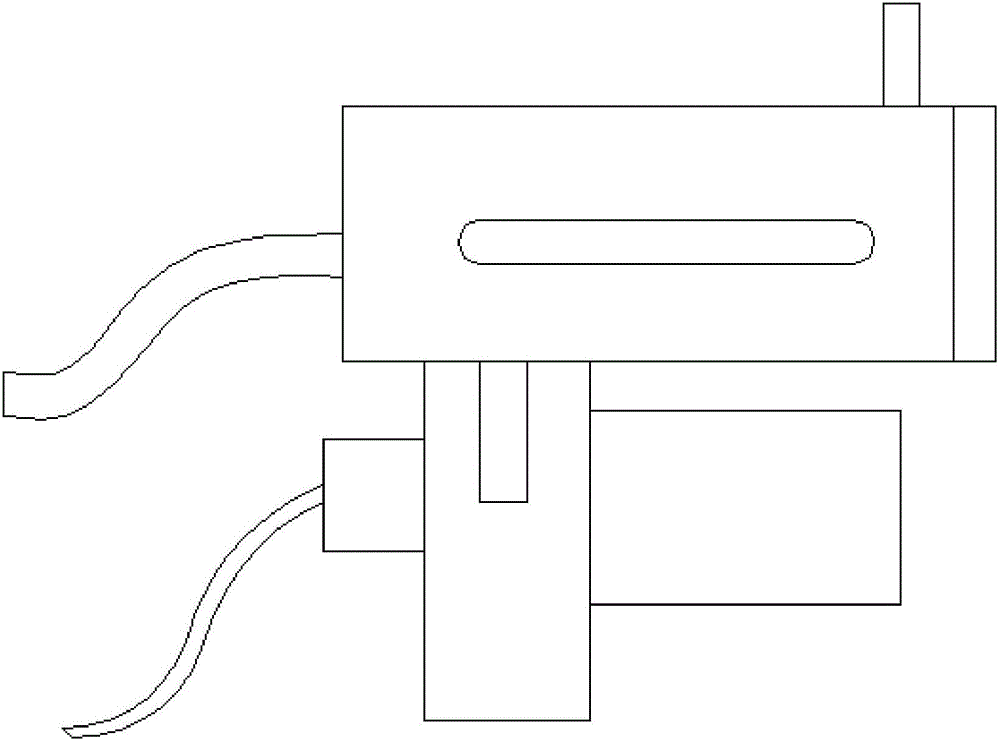

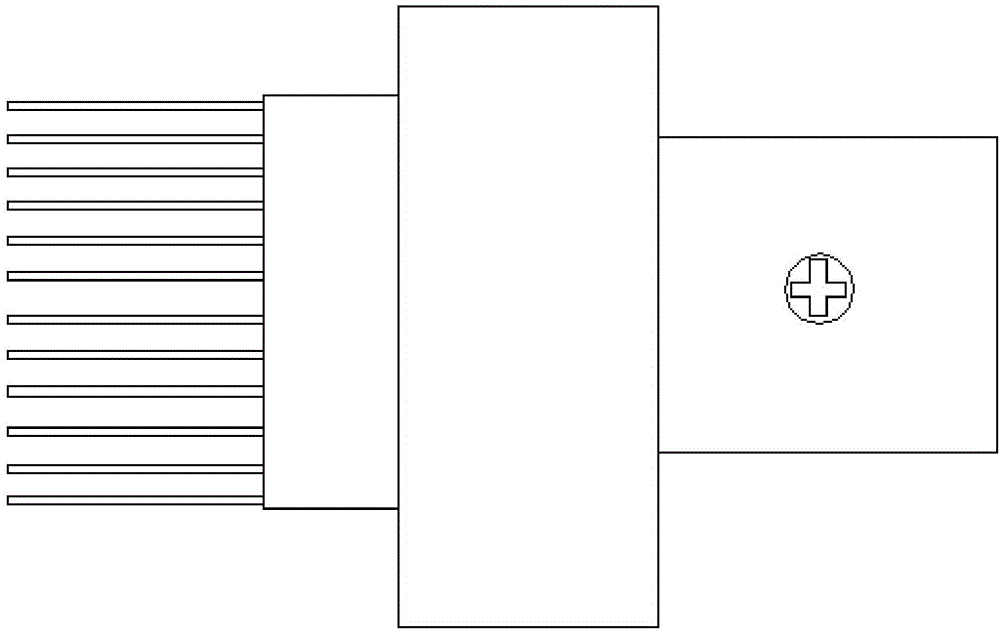

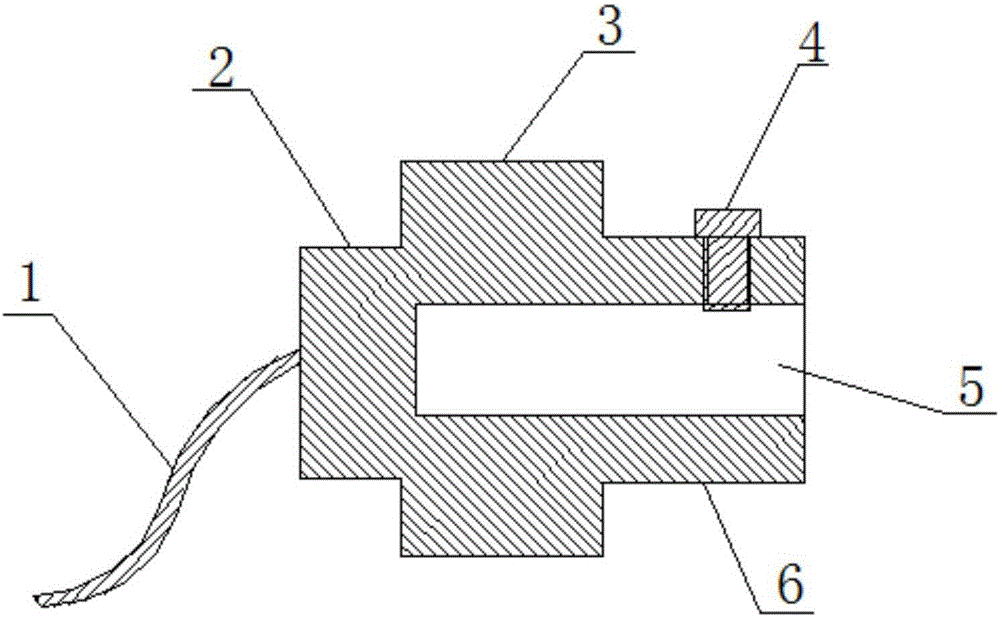

[0024] like Figure 1-Figure 5 As shown, the dotting feeding assembly of the PCB circuit board dotting device includes a dotting connector and a solder feeding device that is clamped on the dotting connector;

[0025] in,

[0026] The dotting joint includes a metal heat conduction block 3, and the two sides of the metal heat conduction block 3 protrude outward to form a connector 2 and a positioning head 6 respectively. The cross section of the piece 1 is an S-shaped curve structure and its end section is a sharp angle. The end face of the positioning head 6 is provided with a positioning hole 5 that goes deep into the connecting head 2, and the side wall of the positioning head 6 is also along the radial direction of the positioning head 6. A positioning screw hole is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com