A combined method of fertilizing holes and strips for base fertilizer of flue-cured tobacco

A fertilization method and basal fertilizer technology, applied in the directions of fertilization method, fertilization device, application, etc., can solve the problems of tobacco leaf production, low fertilizer utilization rate, low quality, etc., and achieve the effects of growth balance, reduction of fertilization labor, and improvement of utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

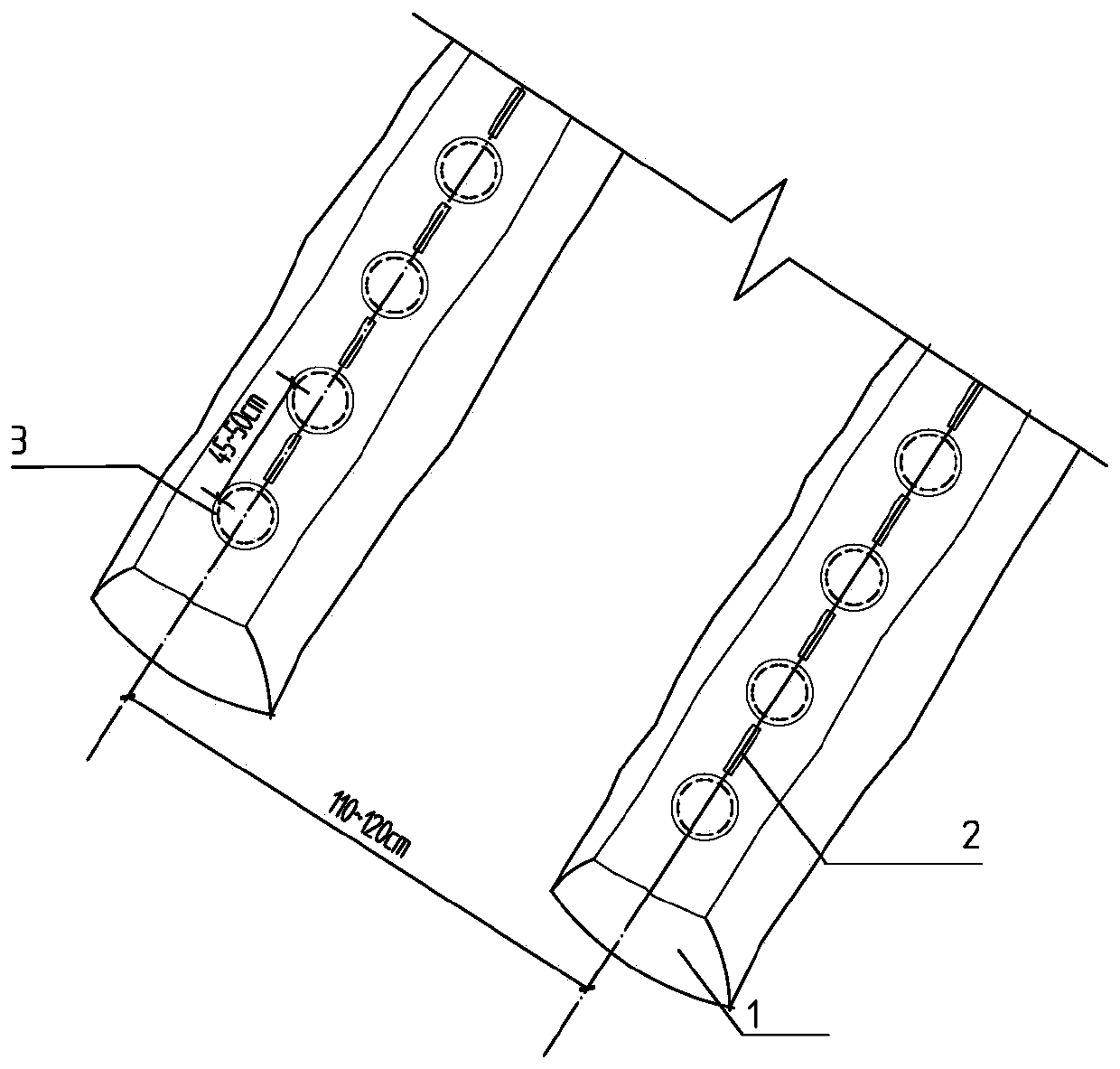

[0036] From 2011 to 2015, Hengyang Tobacco Company carried out the test and demonstration of the fertilization method of flue-cured tobacco holes in five tobacco-growing counties (cities). The fertilization steps are as follows:

[0037] Step 1): Ridge the tobacco field according to 110-120cm, and make holes (holes) at intervals of 45-50cm (the center point position of the hole) in the center of the marked tobacco ridge, the depth of the hole is 18-20cm, and the hole is The diameter is 20-22cm, and 18kg / mu of tobacco-specific base fertilizer is applied in the hole.

[0038] Step 2): then apply 500-600 kg / mu of farmyard manure on the tobacco-specific base fertilizer surface, and the farmyard manure is mainly based on fire soil ash and decomposed pig manure.

[0039]Step 3): After applying the hole fertilizer, one person stands on one side of the ridge body and uses a hoe or rake with a width of 16-20cm to shovel a trench (length 16-20cm, depth 18-20cm, width 2 ~3cm), one perso...

Embodiment 2

[0044] Compared with Example 1, the difference is that step 1) apply 24 kilograms / mu of tobacco special basal fertilizer in the hole; Step 3): apply 36 kilograms / mu of tobacco special basal fertilizer in strips. (The weight of the tobacco-specific basal fertilizer applied in the hole accounts for 40% of the total weight of the tobacco-specific basal fertilizer.)

[0045] The growth rate of high-quality flue-cured tobacco is 24.56%; the fertilization labor is reduced by 0.8 per mu.

[0046] To sum up, the combined fertilization method of hole application and strip application of flue-cured tobacco provided by the present invention can meet the nutritional requirements of flue-cured tobacco in different growth stages under the fertilization position and fertilization amount, and promote the healthy growth of tobacco leaves to fully mature. , to achieve the purpose of high quality and high yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com