Improved cleaning machine

A cleaning machine and rack technology, applied in application, food processing, food science and other directions, can solve the problems of easily damaged fungi, inability to quickly open and close processing efficiency, large cleaning body size, etc. Convenient operability and small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific implementation examples in conjunction with the accompanying drawings.

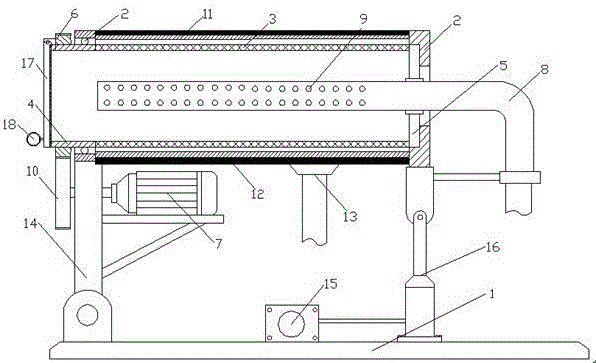

[0014] figure 1 Shows a schematic structural diagram of an improved cleaning machine, including a frame, a bearing seat on the frame, and a screen cylinder. One end of the screen cylinder 3 is connected with a sleeve 4 and the other end is connected with a baffle 5; The ends of the sleeve 4 and the baffle 5 are respectively sealed to the end of the screen cylinder 3; the inner wall of the sleeve 4 is provided with a baffle ring, which is located in the radial direction of the sleeve 4 and is provided There is an inner hole to take and put the cleaning fungus products. The outer side of the sleeve 4 is provided with a gear A5, and the gear A5 is provided with a motor 7 to drive it; the baffle 5 is provided with water spraying in the direction of the axis line The pipe 8, the water spray pipe 8 is a stainless steel round p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com