Process gas purification treatment method

A technology for purification treatment and process gas, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of low degree of automation, low absorption efficiency, and system instability, so as to improve the absorption effect and absorption efficiency. , the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

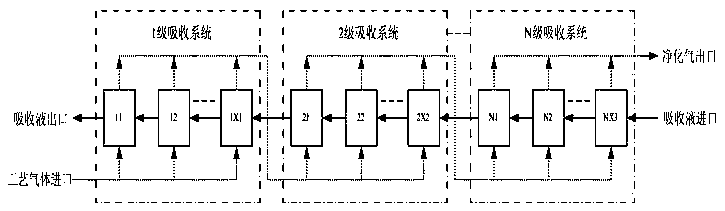

[0017] A process gas purification treatment method, including a gas absorption system, the gas absorption system is composed of multi-stage absorption systems, each stage of absorption system is composed of a certain number of absorption devices, and the number of absorption devices of different stages of absorption systems is different, and the types are the same or different; The absorption liquid advances in the opposite direction according to the gas flow, and the absorption devices of each stage of the absorption system are connected in series through a balance connecting pipe, and the liquid level of the circulation tank of each absorption device maintains a certain liquid level difference along the flow direction of the absorption liquid to advance forward as the absorption circulation liquid Clean liquid enters the outlet of the purified gas, liquid exits the inlet of the process gas, the concentration of the output liquid is adjusted by the amount of liquid, and the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com