Method for producing microphone unit, thermal-oxidative layer and low-stress structural layer

A technology of thermal oxidation layer and structural layer, which is applied in the direction of manufacturing microstructure devices, microstructure technology, microstructure devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

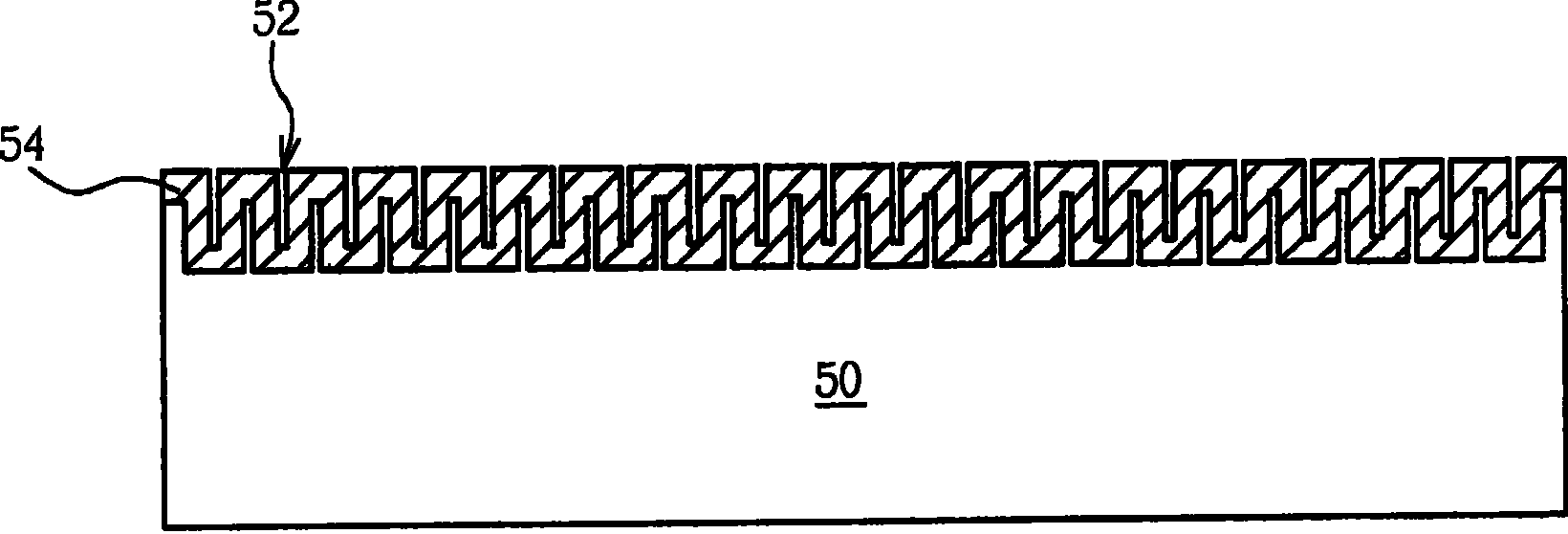

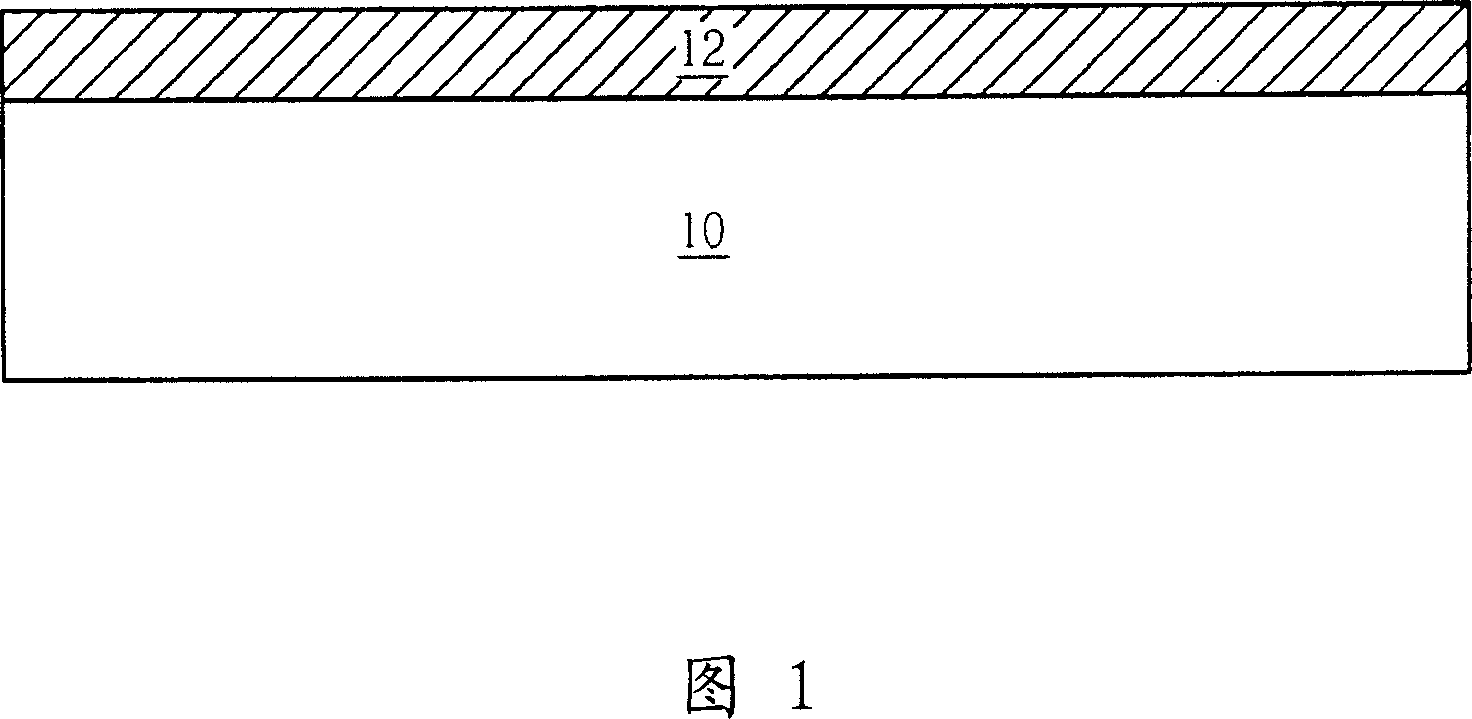

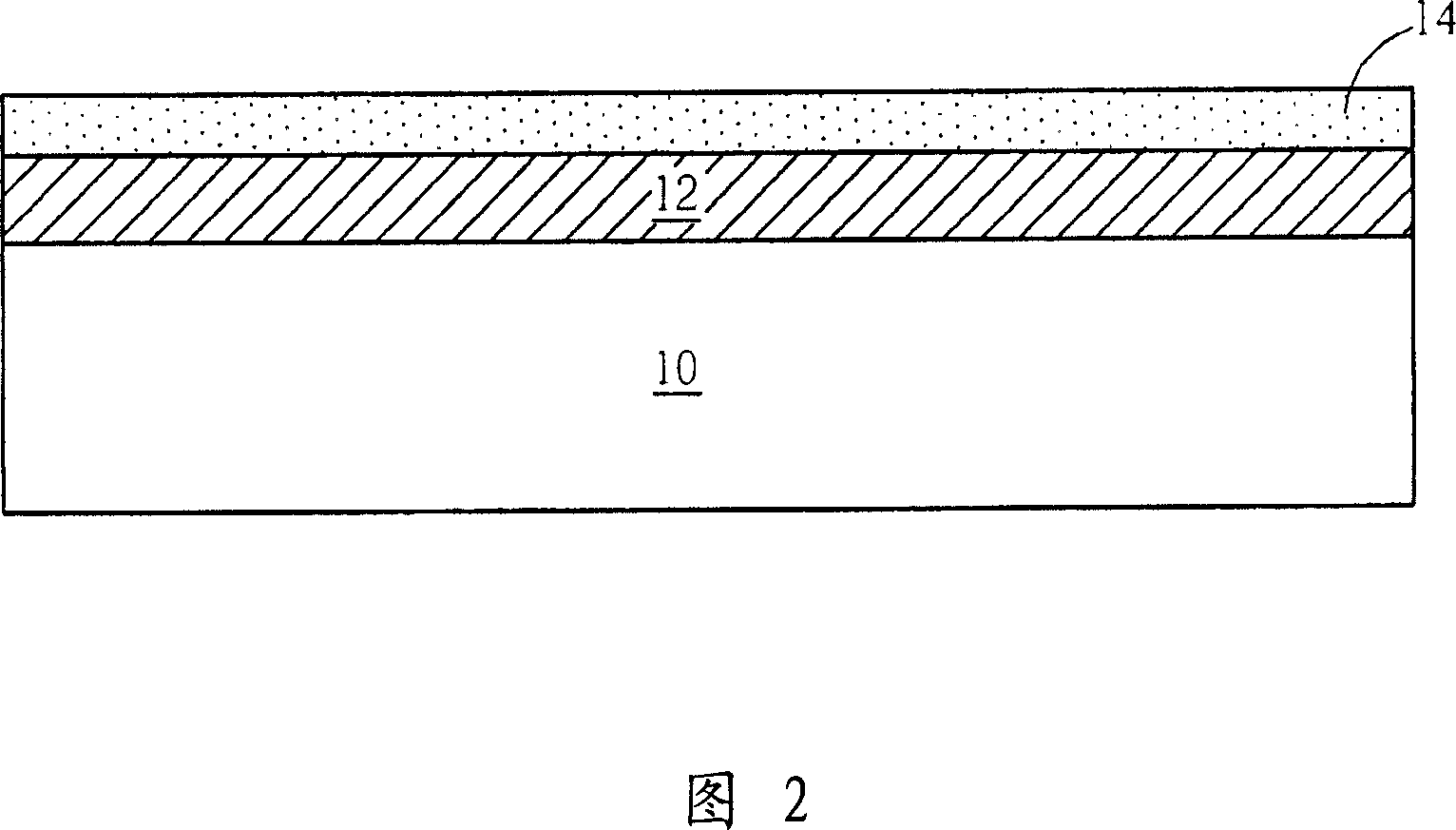

[0024] Please refer to Figure 7 to Figure 15. 7 to 15 are schematic diagrams of a method for making a miniature microphone device according to a preferred embodiment of the present invention, wherein for enlarging the features of the present invention, only a single miniature microphone device is shown in the figure, and the method for making a miniature microphone device in the present invention It can be divided into three main stages, wherein the first stage is the step of making the thermal oxidation layer (as shown in Figures 7 to 9), the second stage is the step of making the structural layer (as shown in Figures 10 to 13), The third stage is the step of making the cavity (as shown in FIGS. 14 to 15 ). As shown in FIG. 7 , first provide a substrate 50, such as a silicon substrate or a silicon-covered insulating substrate, and then use a deep etching technique, such as an inductively coupled plasma deep etching technique, an X-ray deep etching technique or an electron cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com