Glue mixing machine

A technology of glue mixer and mixing head, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of heavy weight, inconvenient on-site use, large size of the glue mixer, etc., achieve light weight, reduce equipment cost, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

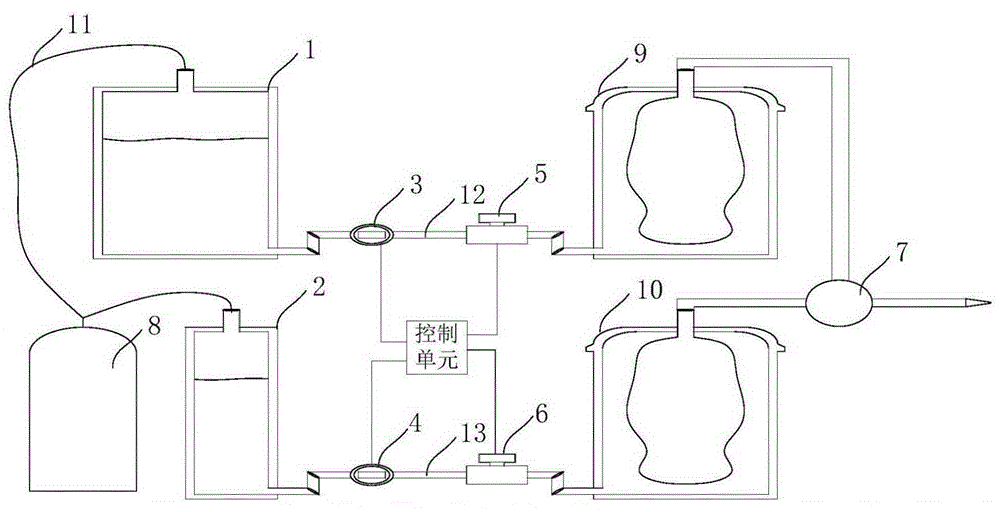

[0019] Such as figure 1 As shown, a rubber mixing machine includes a mixing head device 7, an air compressor 8, a first raw material sealed container 9 with a soft bag inside, a second raw material sealed container 10 with a soft bag inside, and a first liquid sealed container. Container 1, the second liquid sealed container 2, the first flow meter 3, the second flow meter 4, the first solenoid valve 5, the second solenoid valve 6 and the control unit; the output end of the soft bag of the first raw material sealed container 9 is connected to The output end of the flexible bag of the second raw material airtight container 10 is connected with two input ends of mixing head device 7 respectively; The gas input end of the second liquid sealed container 2 is connected, and the air compressor 8 is used to press gas into the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com