Welding method for steel Q390GJC for building structure

A technology of steel for building structures and welding methods, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as cracks, unformed welding methods and processes, and increased welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0032] The chemical composition of building structural steel Q390GJC is shown in Table 1, and the mechanical properties are shown in Table 2.

[0033] Table 1 Chemical Composition of Q390GJC Building Structure Steel (%)

[0034]

[0035] Table 2 Mechanical properties of Q390GJC steel for building structures

[0036]

[0037] Welding method of steel Q390GJC for building structure:

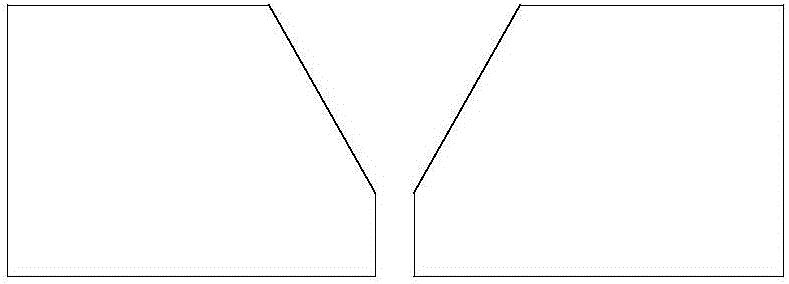

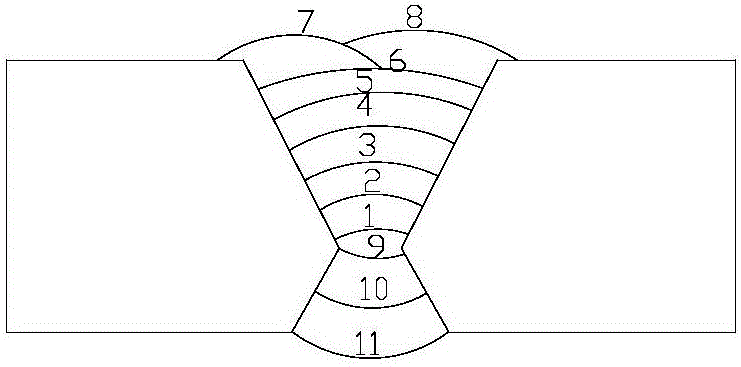

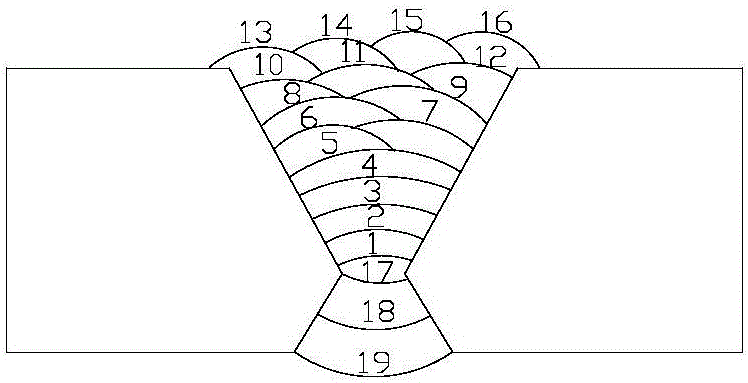

[0038] 1 Welding joints adopt butt flat welding, butt horizontal welding, corner butt flat welding, T-shaped fillet horizontal welding, and T-shaped fillet non-penetration flat welding.

[0039] 2 The welding method adopts submerged arc automatic welding, CO 2 Gas shielded welding.

[0040] 3 Preheat to 60°C before welding.

[0041] 4. Multi-layer and multi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com