Tooth profile type ring die curing forming device

A solidification molding and ring die technology, which is used in material molding presses, presses, manufacturing tools, etc., to achieve the effects of large-scale production, slow wear of parts, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

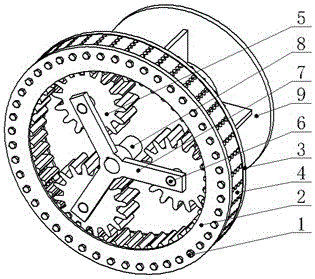

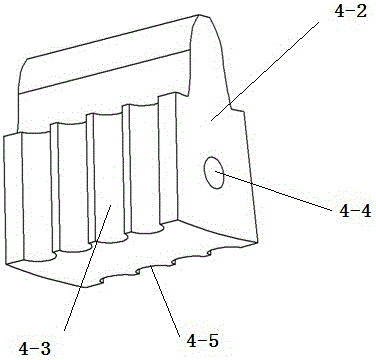

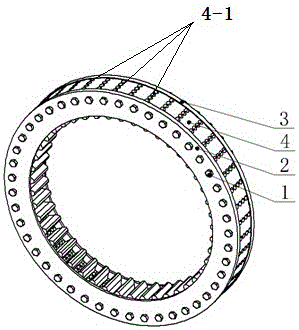

[0018] Such as Figures 1 to 5 As shown, a tooth type ring mold curing molding device includes a support frame 9, a ring mold 4 is fixed on the side of the support frame 9, a main shaft 8 is fixed in the middle of the support frame 9, and the main shaft 8 is located at the In the ring die 4 , a motor is arranged inside the support frame 9 , and the output shaft of the motor is connected to the main shaft 8 . The ring die 4 includes an annular upper cover plate 2 and an annular lower supporting plate 3, and the gap between the annular upper cover plate 2 and the annular lower supporting plate 3 is filled by several ring modules, each of which is composed of ring modules. The module body 4-2 is composed of the first half cogging 4-3 and the second half cogging 4-5 on both sides of the ring module body, and the first half cogging 4-3 of each ring module is connected with another The second half tooth groove 4-5 of a ring mold fits to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com