Method and system for protecting trains against collisions

A technology for collision protection and trains, applied in the direction of railway vehicle wheel guards/buffers, railway car body parts, transportation and packaging, etc., can solve problems such as uncontrollable damage to vehicles, differences in energy absorption characteristics, etc., to improve safety, Stable energy-absorbing properties and extended length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

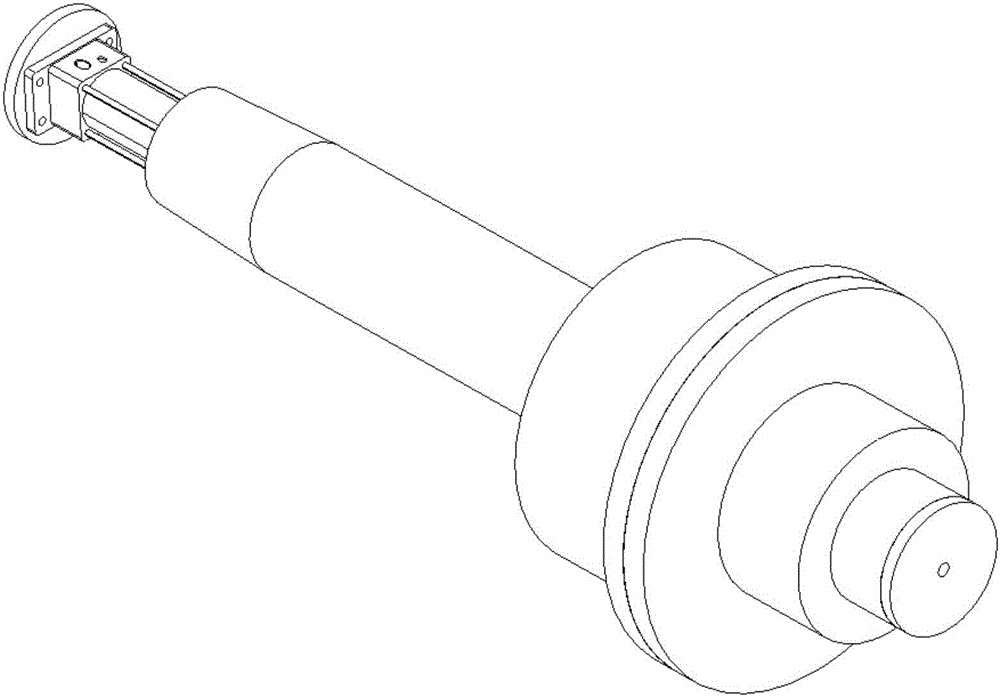

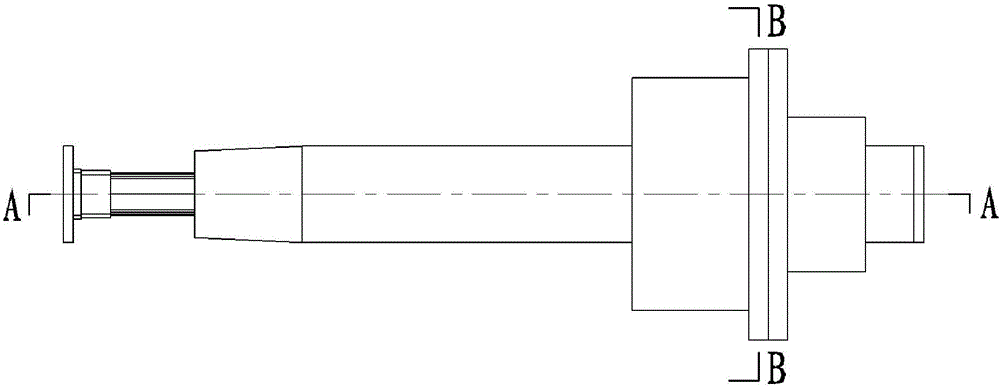

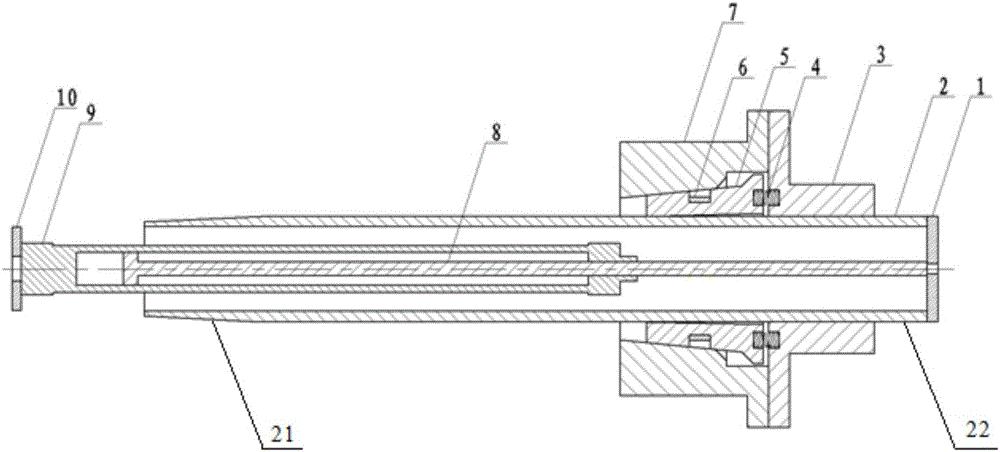

[0051] Figure 1-9 is the energy absorbing device structure of Embodiment 1 of the present invention, wherein Figure 1~4 is the state where the energy-absorbing tube shrinks in the car body when the train is running normally, Figure 5-8 It is a structural diagram of the energy-absorbing device outside the vehicle body with the energy-absorbing tube stretched out before the collision accident. After the collision accident, the energy-absorbing tube will change from Figure 7 Extrude in the inner via hole 54 that the four block sleeves 5 shown together form, specifically Figure 7 The middle energy-absorbing tube is extruded from right to left, and the inner diameter of the energy-absorbing tube after collision extrusion becomes smaller and absorbs energy.

[0052] Specifically, such as Figure 1~4 As shown, when the train is running normally, the energy-absorbing tube 2 shrinks inside the car body under the pulling force of the cylinder piston rod 8, and the four limit sl...

Embodiment 2

[0055] Figures 10-14 is the energy absorbing device structure of Embodiment 2 of the present invention, wherein Figure 10-12 is the state where the energy-absorbing tube shrinks in the car body when the train is running normally, Figure 13 It is a structural diagram of the energy-absorbing device outside the vehicle body with the energy-absorbing tube stretched out before the collision accident. After the collision accident, the energy-absorbing tube will change from Figure 13 Extrude in the inner via hole 54 that the four block sleeves 5 shown together form, specifically Figure 13 The middle energy-absorbing tube is extruded from right to left, and the inner diameter of the energy-absorbing tube after collision and extrusion is reduced to absorb energy.

[0056] specifically, Figure 10 Shown is the structure schematic diagram of the automatic retractable energy-absorbing device of the limit sleeve 5, the positioning ring 6 is connected with the movable pin shaft 12,...

Embodiment 3

[0058] In the present invention, when the train is running normally, the structure of the train collision protection system is as follows: Figure 15 In the structure shown, the anti-climbing tooth at the end of the energy-absorbing tube is located closer to the car body (passenger compartment) than the coupler. After the instrument or manpower recognizes the train collision danger signal, the telescopic drive structure actively pushes the energy-absorbing tube and the anti-climbing gear to a position away from the car body. After the energy-absorbing tube is pushed out, the structure of the train collision protection system is as follows Figure 16 In the shown structure, the anti-climbing tooth at the end of the energy-absorbing tube is located far away from the car body compared with the coupler. For example, the coupler stretches out 0.5m in front of the car body, while the anti-climbing teeth stretch out 1m in front of the car body. When the train collides, the anti-climb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com