Joint connecting device suitable for assembly type structure

A node connection and prefabricated technology, applied in the direction of building structure and construction, can solve problems such as affecting the construction progress, increasing the difficulty of construction, and building collapse, and achieve the effect of reducing earthquake response, simplifying node design, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

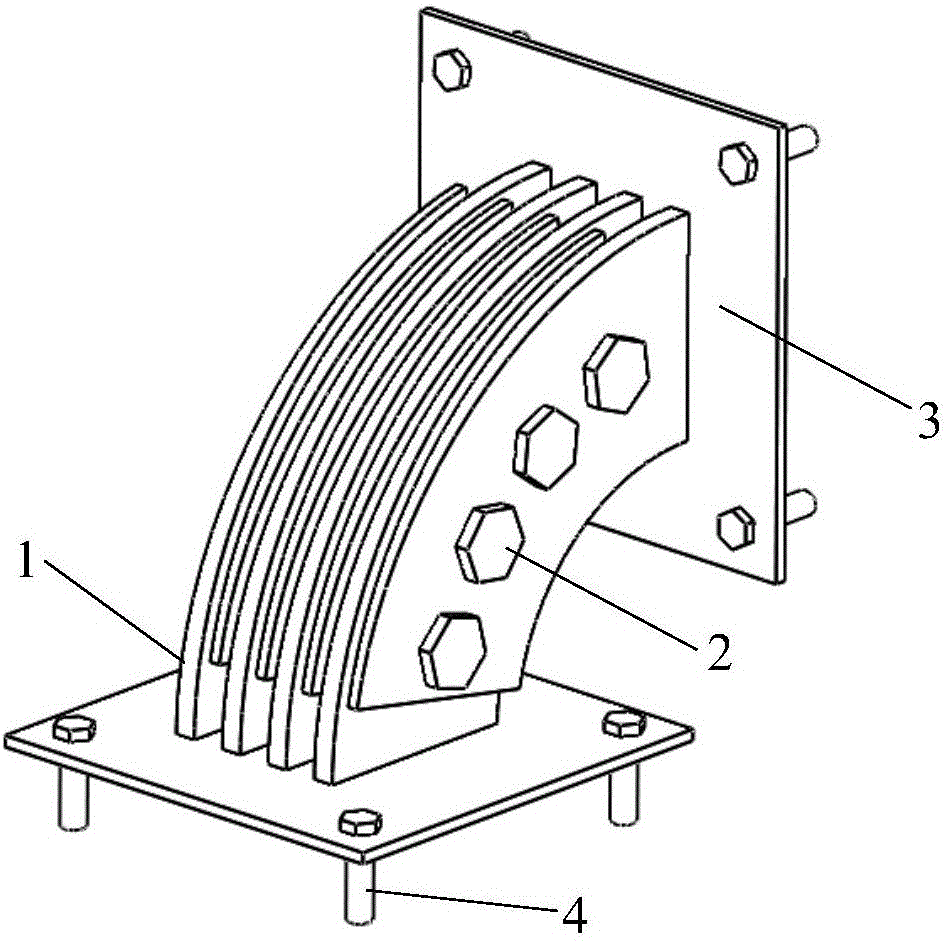

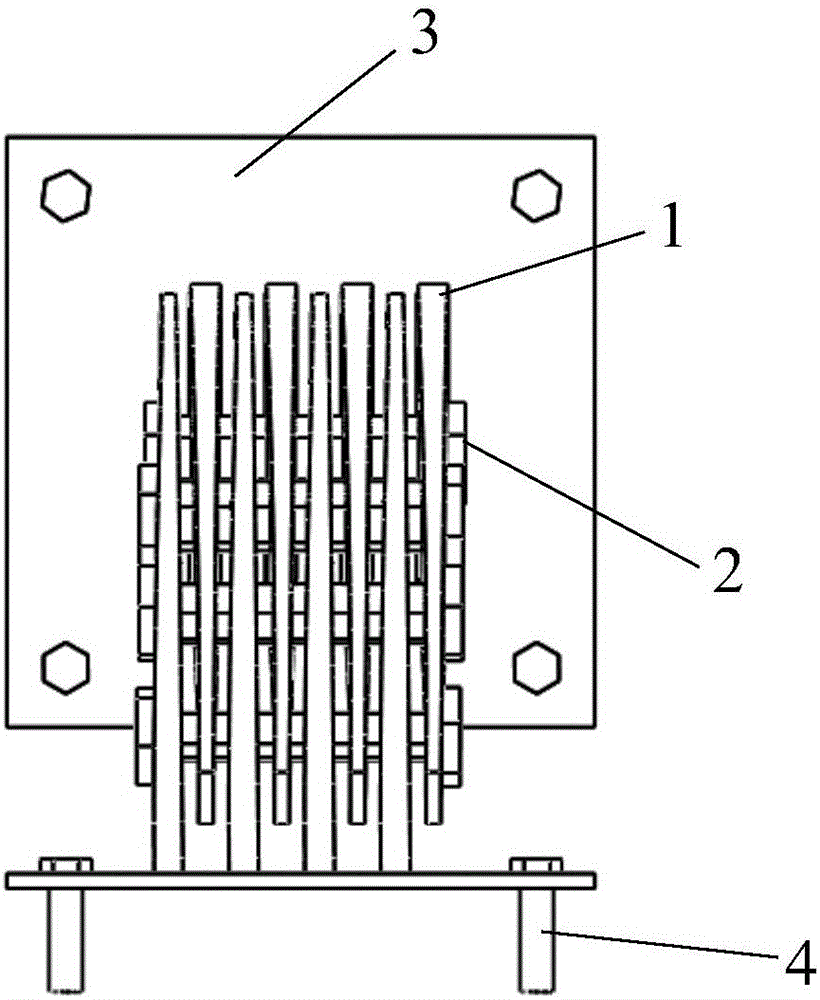

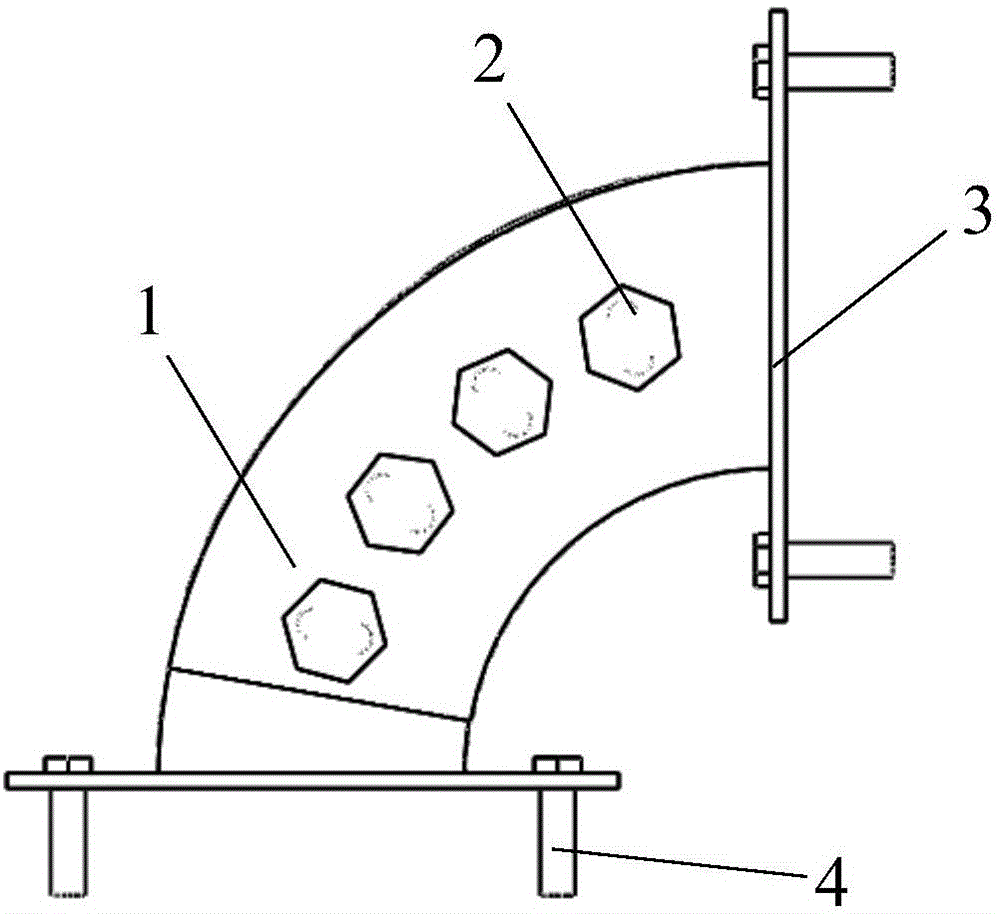

[0031] The specific implementation manner and working principle of the present invention are given below in conjunction with the accompanying drawings. The drawings are all in simplified form, and are only used to illustrate the embodiments of the present invention for convenience.

[0032] The present invention is a novel node connection device applicable to assembled structures such as figure 1 , figure 2 and image 3 As shown, it includes: connecting piece 1 , shear anchor 2 , connecting plate 3 and bolt 4 . Wherein, the connecting plate 3 in the figure is two, that is, the first connecting plate and the second connecting plate, and a group of connecting pieces are respectively connected on each connecting plate, wherein the first connecting piece connected to the first connecting plate There are 4 connecting pieces in the first connecting piece group; the second connecting piece group is connected to the second connecting piece group, and there are also 4 connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com