Ball valve upstream and downstream seal control method and control system

A technology of sealing control and control system, which is applied in the fields of hydropower generation, engine components, machines/engines, etc., can solve the problems of low maintenance efficiency, long return time of units, hidden safety hazards, etc., so as to improve safety and efficiency, shorten return Backup time, avoidance of investment and the effect of dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

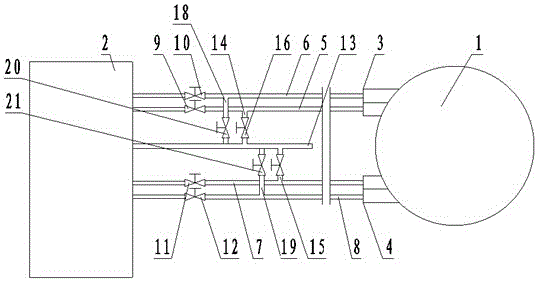

[0018] Example. A ball valve upstream and downstream sealing control method, such as figure 1 As shown, the method is between the ball valve pressure oil tank 1 and the sealing control cabinet 2, the maintenance seal input cavity pipeline 5, the maintenance seal exit cavity pipeline 6, the working seal input cavity pipeline 7 and the working seal exit cavity pipeline 8 are provided with a first valve 9, a second valve 10, a third valve 11 and a fourth valve 12; and the fourth valve 12 to manually shield and seal the control cabinet 2, thereby preventing the unit from rotating and improving the safety and efficiency of the unit maintenance.

[0019] After the first valve 9, the second valve 10, the third valve 11 and the fourth valve 12 are closed, the fifth valve 16 and the sixth valve 17 are manually opened, and the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com