Automatic control method of cooling capacity of outer cooling unit

A technology of cooling capacity and unit, applied in the direction of engine control, pump control, machine/engine, etc., can solve the problems of difficult to accurately adjust the cooling capacity of external cooling, smoothly control the temperature of the cooled medium, and reduce the service life of the fan, so as to prolong the service life. The effect of life, adjustment range optimization, and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

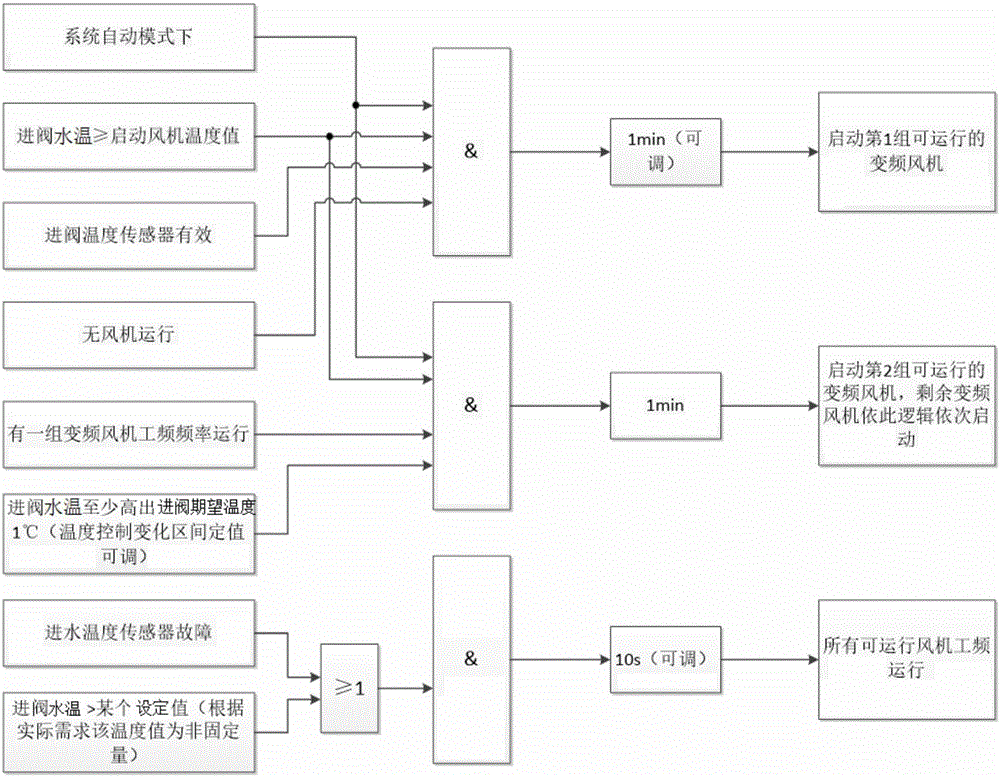

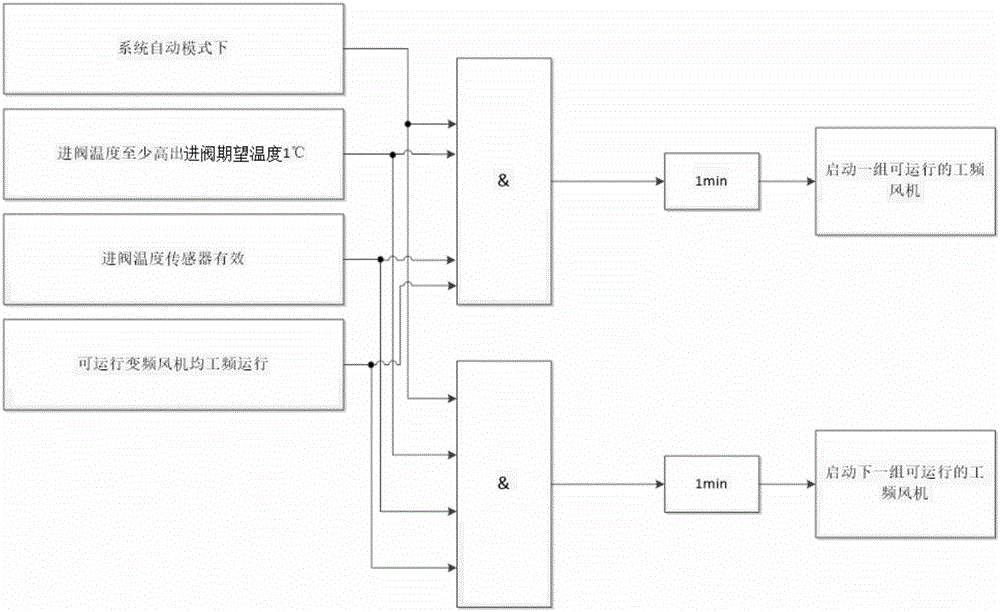

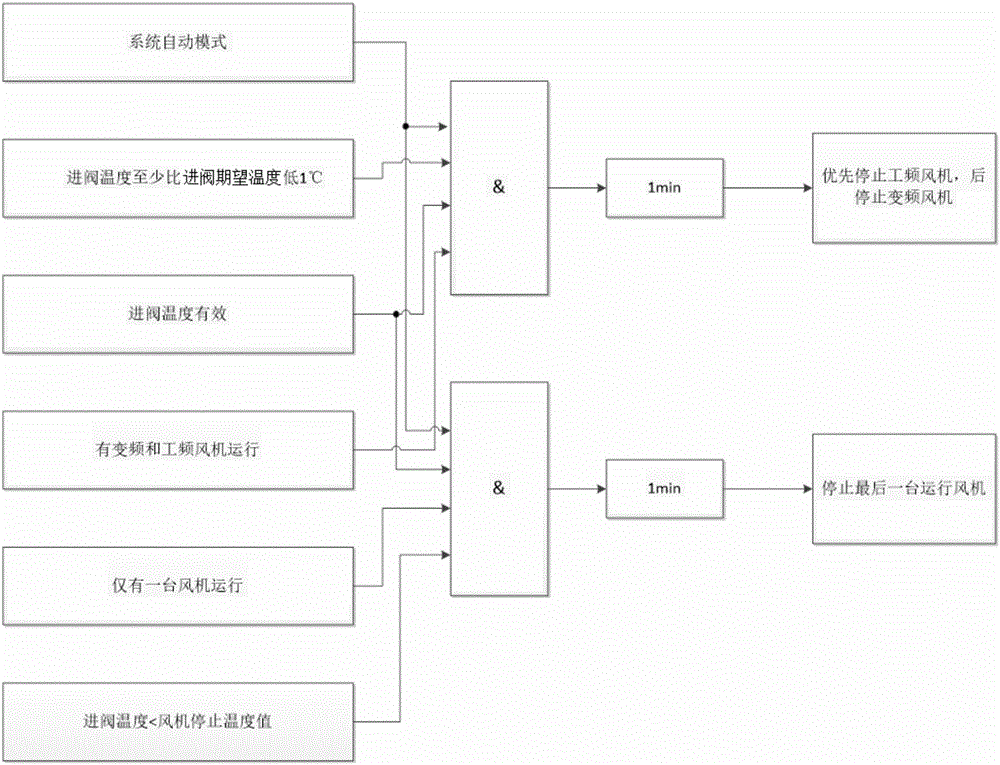

[0027] Such as Figure 1 to Figure 5 As shown, an automatic control method for the cooling capacity of an external cooling fan group, the external cooling fan group includes M frequency conversion fans and N power frequency fans, and the frequency conversion fans and power frequency fans are respectively controlled by logic circuits to start and stop; the automatic The control method includes a starting step and a stopping step;

[0028] The starting step: comparing the inlet valve water temperature with the inlet valve expected temperature, when the inlet valve water temperature is higher than the inlet valve expected temperature, start the variable frequency fan and the power frequency fan through the logic circuit;

[0029] The stopping step: c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com