Automatic mobile cotton bale and cotton sampling device and sampling method thereof

An automatic sampling device and mobile technology, applied in the field of machinery and equipment, can solve the problems of not being able to obtain samples of cotton packaging materials and cotton bale binding materials at the same time, not being able to meet flexible sampling requirements, and inspection errors, so as to save labor and avoid man-made Error, the effect of avoiding inspection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments.

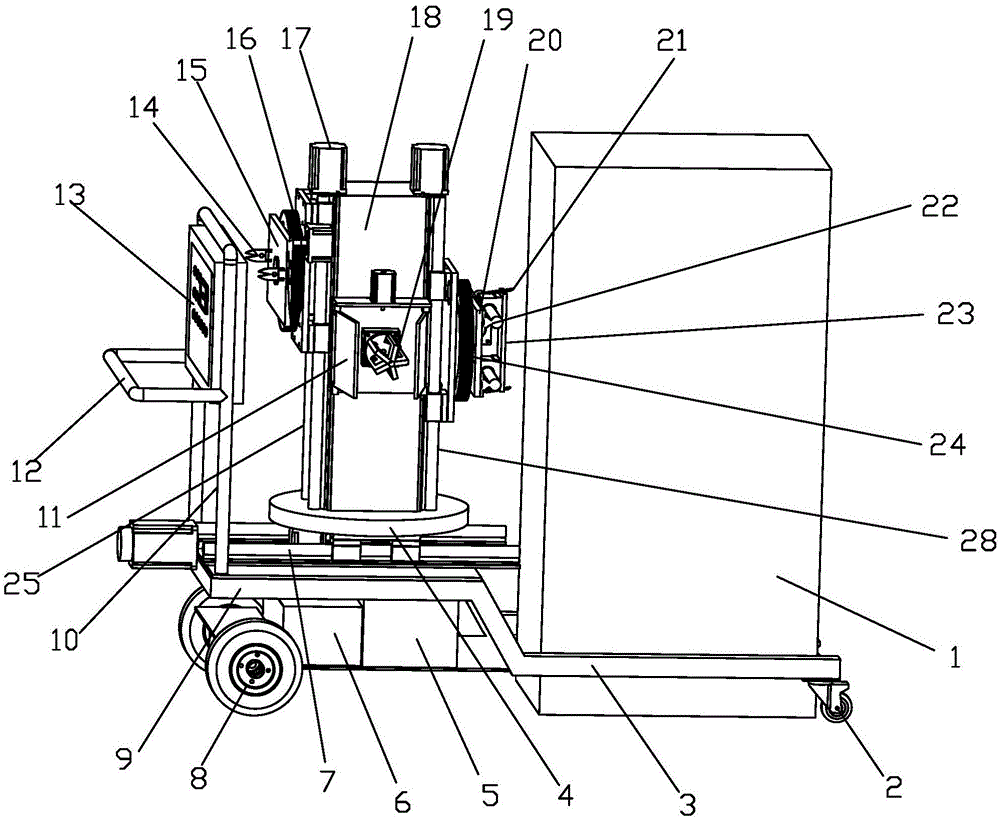

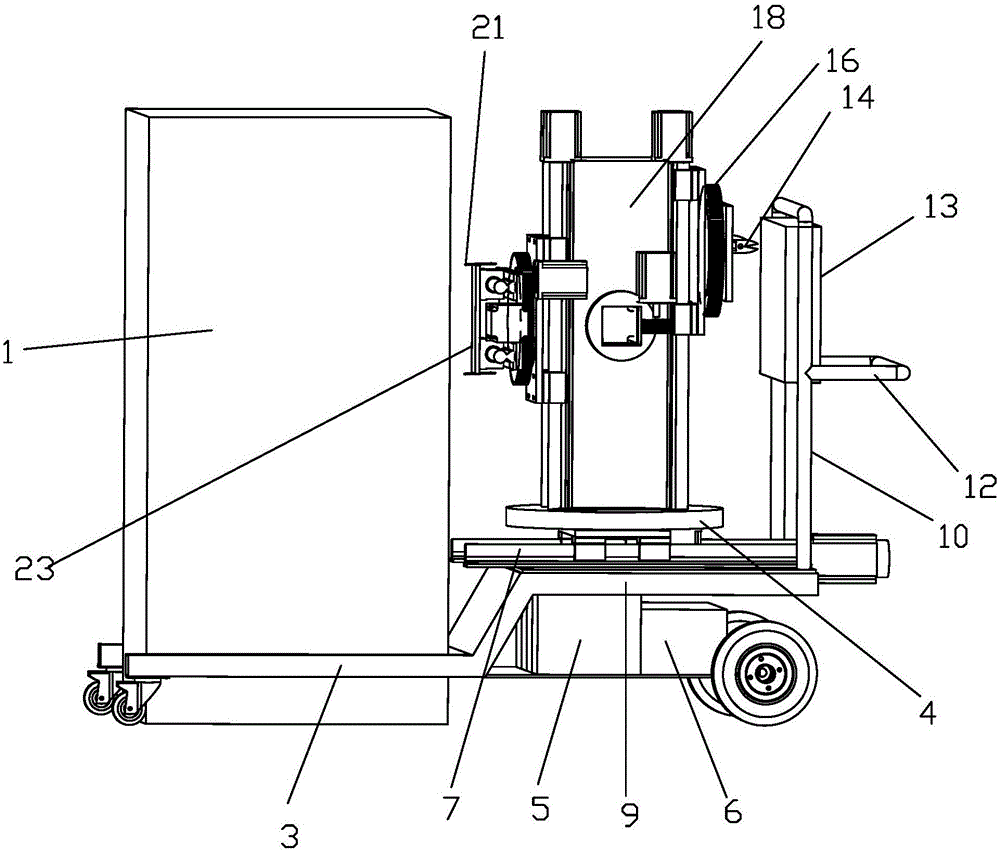

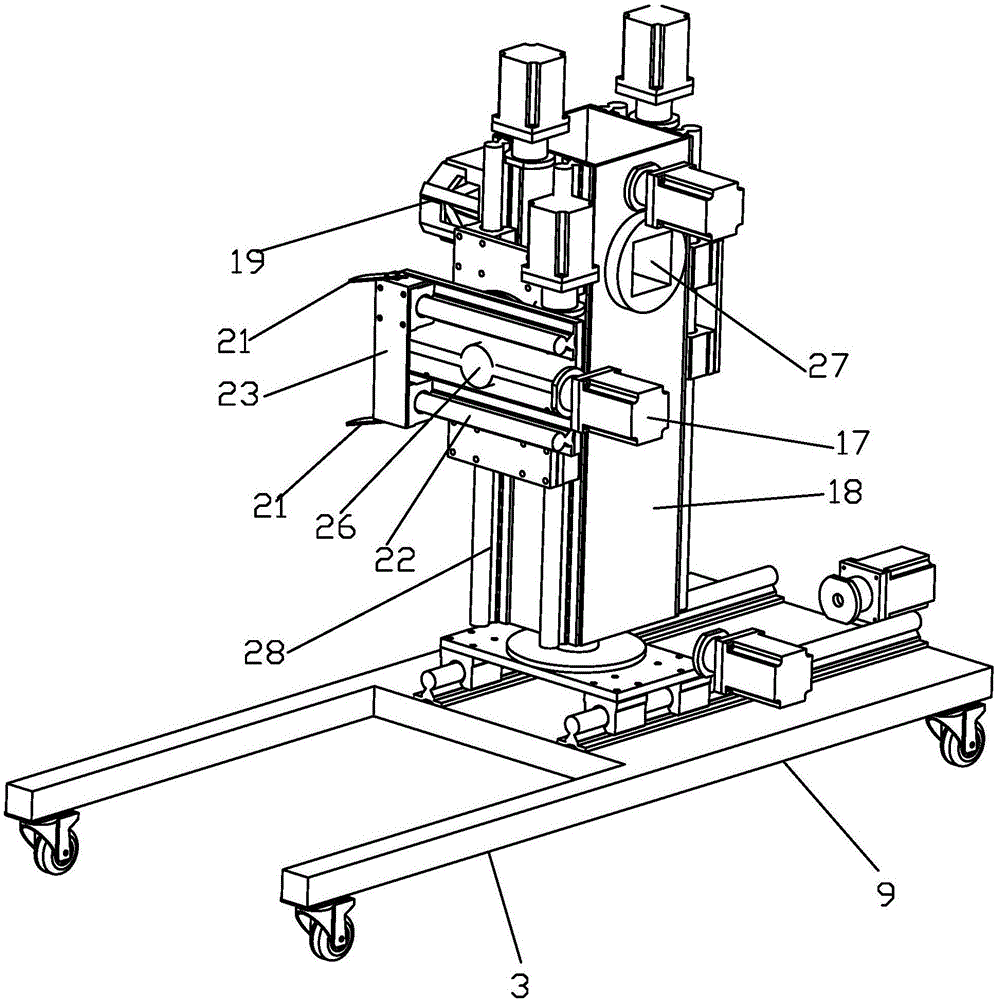

[0040] Such as Figure 1-3 A movable cotton bale and automatic cotton sampling device is shown, which includes a base 9, the base 9 is provided with a moving guide rail 7 facing the direction of the cotton bale 1 to be sampled, and a station rotary table is provided on the moving guide rail 7 through a rotatable mechanism 4. The station rotary table 4 is provided with a station platform 18, and the station platform 18 is respectively provided with a cotton packaging material cutting mechanism, a cotton bale binding material shearing mechanism and a cotton sample grasping mechanism; wherein, the rotatable mechanism is a turntable, The flower wheel or similar components, the rotatable mechanism is connected with the straight motor and the rotary motor, so that the station rotary table 4 can move linearly along the moving guide rail 7, and can also rotate.

[0041] Cotton pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com