Method and device for measuring sediment concentration of vertical fracture surface of model by means of optical method

A technology for measuring models and concentrations, which is applied in the field of sediment concentration measurement, can solve the problems of inaccurate measurement of sediment content, unmeasured characteristics of sediment movement, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

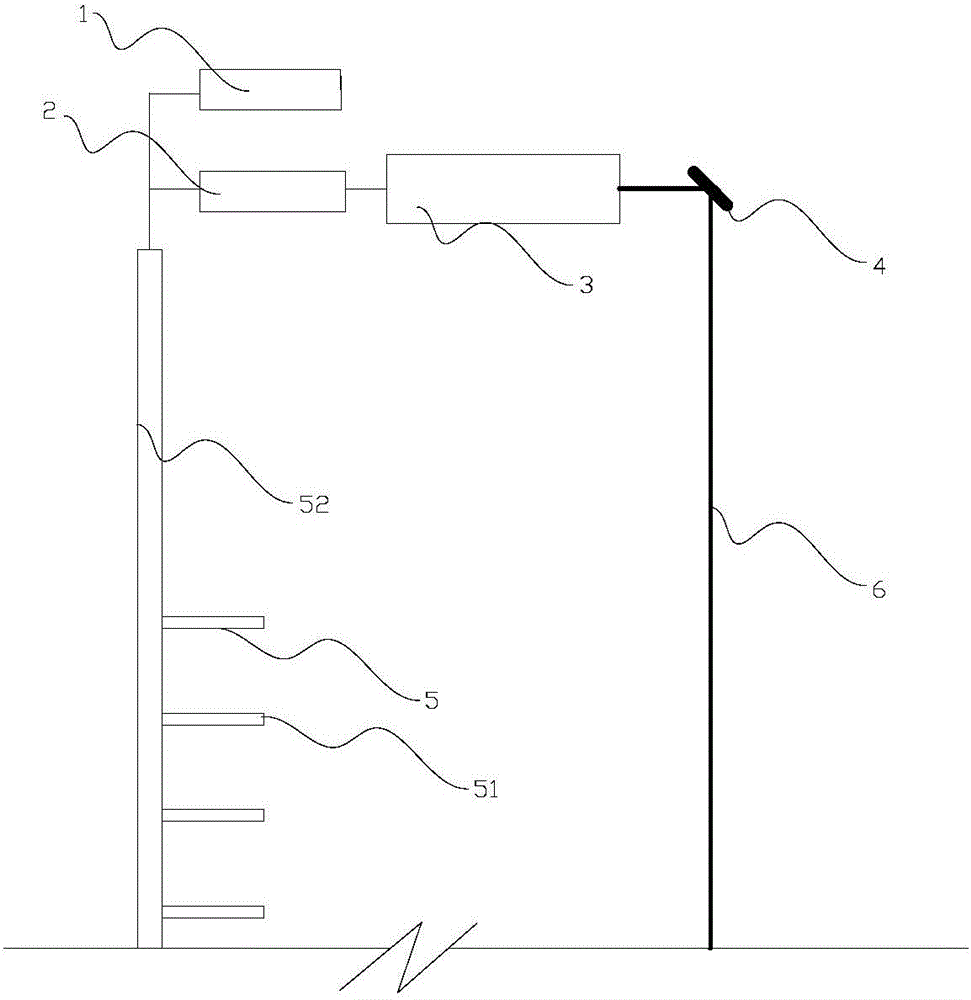

[0033] The invention discloses an optical method for measuring sediment concentration in a vertical section of a model, comprising: an image acquisition module 1, a synchronization module 2, a laser 3, and a reflector 4. The above image acquisition module includes an endoscope 5 and an exposure device.

[0034] Described endoscope 5 is a fiber optic endoscope;

[0035] Described fiber optic endoscope comprises: a plurality of optical fiber lens 51, optical fiber 52, photoreceptor, fiber optic lens 51; Described laser device 3 emits laser light 6, and laser light 6 is imaged on the photoreceptor after irradiating sediment, after imaging, passes through optical fiber The image is transmitted to the photoreceptor, and the photoreceptor is exposed under the control of the exposure device, and the electrical signal after exposure is transmitted to the image acquisition module 1;

Embodiment 2

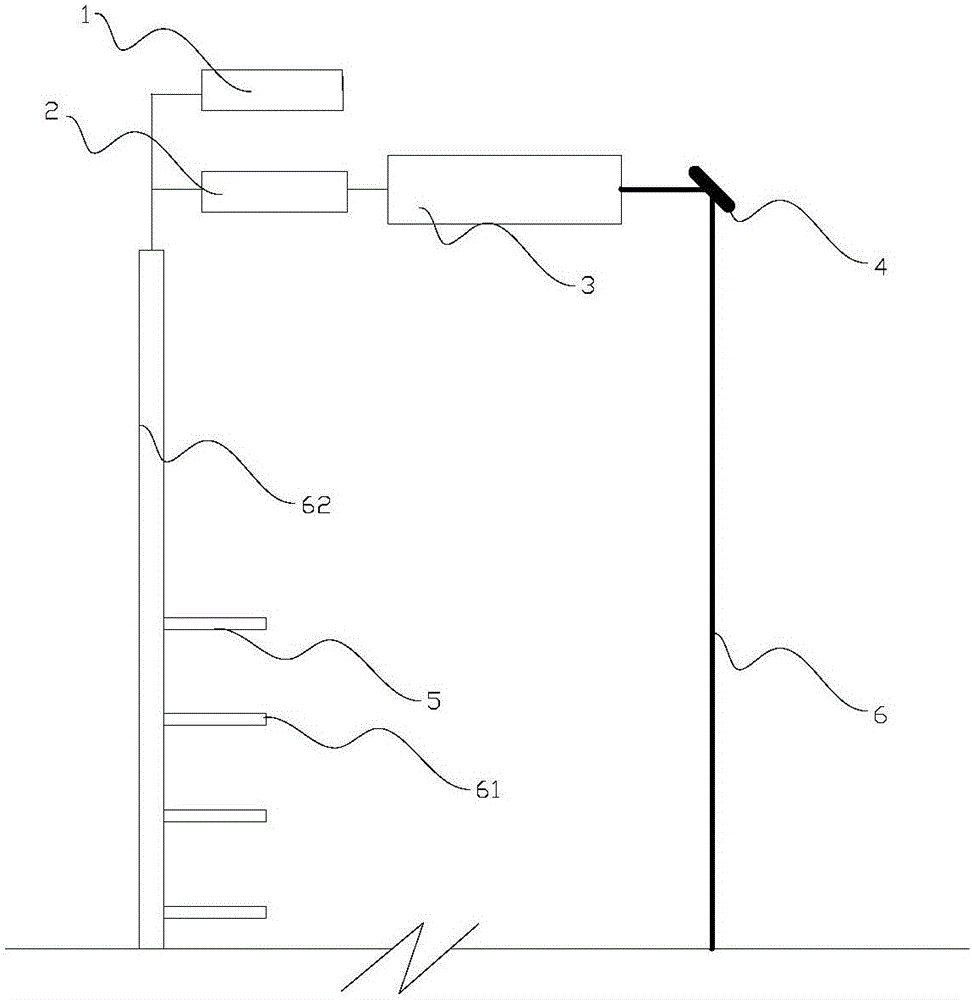

[0037] The invention discloses an optical method for measuring sediment concentration in a vertical section of a model, comprising: an image acquisition module 1, a synchronization module 2, a laser 3, and a reflector 4. The above image acquisition module includes an endoscope 5 and an exposure device.

[0038] Described endoscope 5 is electronic endoscope;

[0039] Described electronic endoscope comprises: a plurality of lens 61, photoreceptor, transmission line 62, lens 61; Described laser device 3 emits laser light 6, and laser light 6 is imaged on photoreceptor after irradiating sediment, after imaging, exposure device controls The photoreceptor converts the optical signal into an electrical signal and transmits it to the image acquisition module 1 through the transmission line 62;

[0040] The exposure device and the laser 3 are connected to each other through the synchronization module 2. During the exposure process, the synchronization module 2 excites the laser to emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com