Industrial CT scanning test system

A CT scanning and testing system technology, applied in the direction of applying stable tension/pressure to test material strength, image data processing, instruments, etc., can solve problems such as difficulty in ray penetration, image resolution reduction, and increased loading tonnage. Achieve the effect of improving test efficiency and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The core of the present invention is to provide an industrial CT scanning test system, which can realize real-time loading of test samples, improve the accuracy of system simulation, and can realize multi-directional loading of samples to meet test requirements.

[0051] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

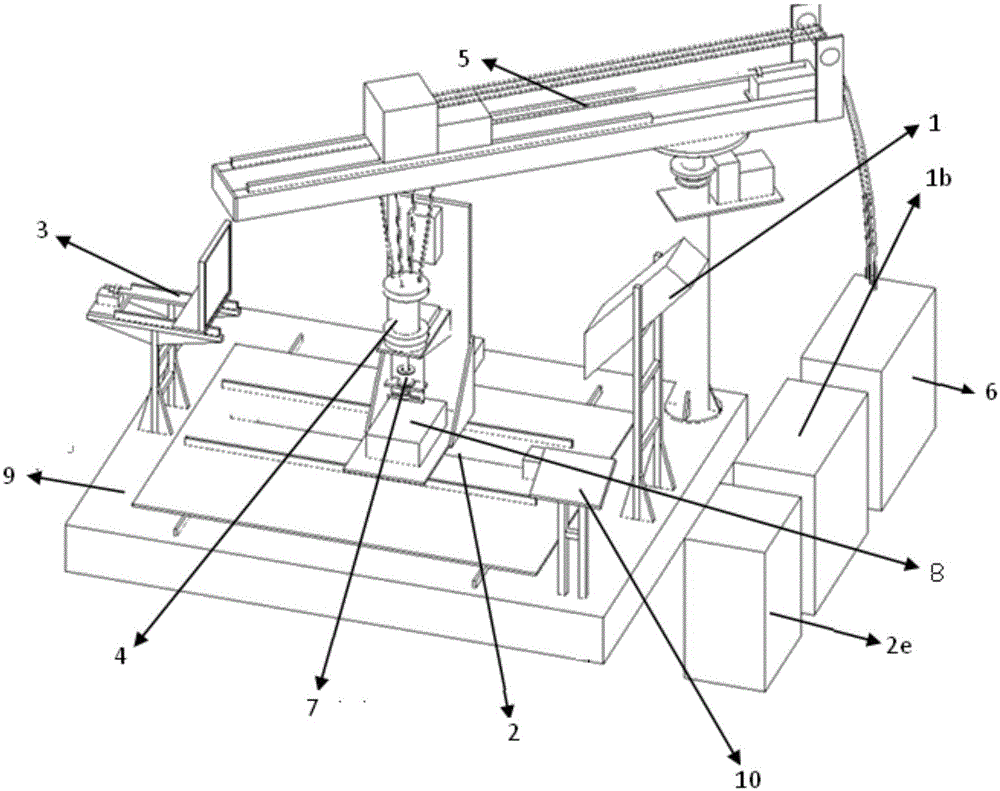

[0052] Please refer to figure 1 , figure 1 It is a structural schematic diagram of an industrial CT scanning test system in an embodiment of the present invention.

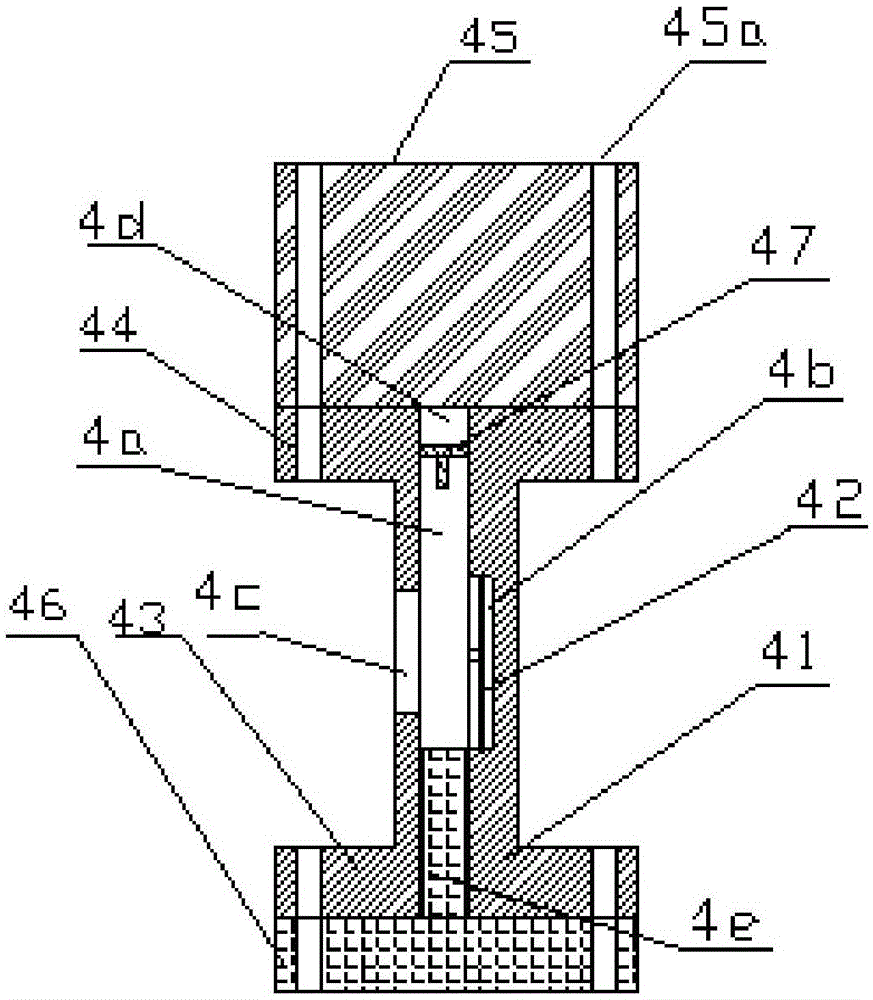

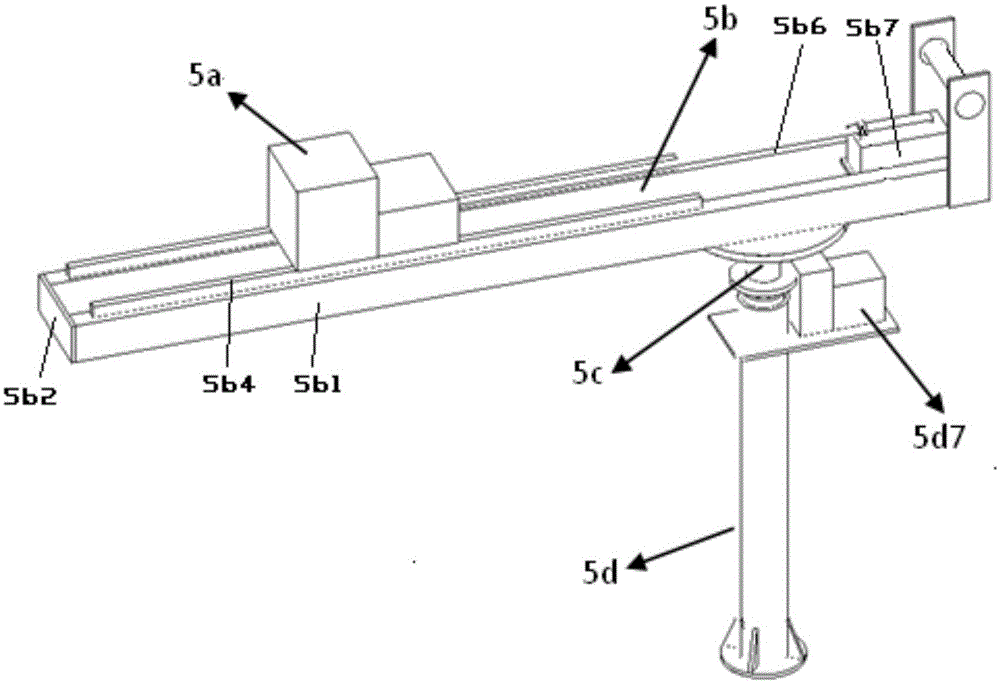

[0053] The present invention provides an industrial CT scanning test system, which includes a test base 9 and a multi-axis motion turntable 2 supported on the test base 9, a radiation generating device 1, an image acquisition device 3, a fluid pressure loading device 4, control device6. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com