Energy efficiency analysis system of interlocking equipment

A technology of equipment and linkage, applied in the field of energy efficiency analysis of linkage equipment, can solve the problems of neglecting the linkage relationship of equipment, the optimization effect of energy-related parameters is not ideal, and the influence of linkage equipment is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

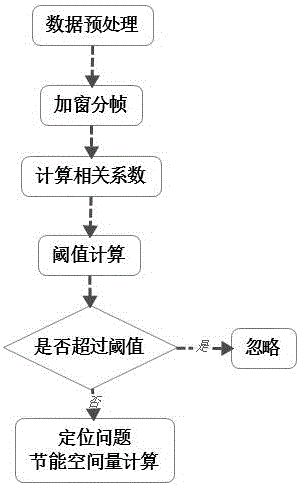

[0053] see figure 1 , the invention discloses a method for energy efficiency analysis of linkage equipment, comprising:

[0054] (1) Data collection and preprocessing

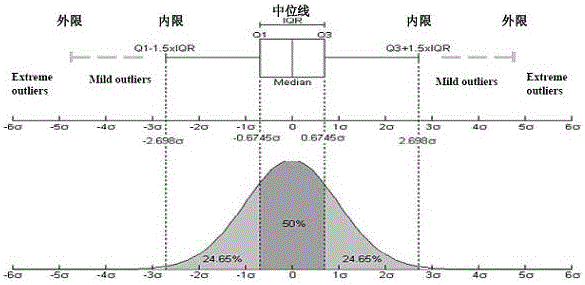

[0055] Due to the complex working environment of the production site, there are more or less missing data and abnormal data during the data collection process. Therefore, before the data is analyzed, it is necessary to perform preprocessing operations on the raw data of the linkage equipment in the production system. The method of the preprocessing operation is to perform data completion and abnormal value cleaning on the original energy consumption related parameter sampling data according to the historical energy consumption related parameter sampling data combined with the production system mechanism.

[0056] 1) Data completion

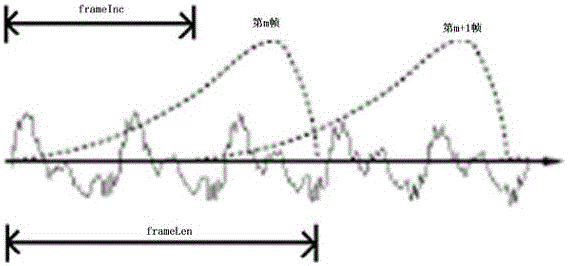

[0057] The data completion of the present invention is sorted according to the generation time of the sampling data of the energy consumption related parameters, and adopts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com