X-ray counting machine

An X-ray and spotting technology, which is applied in the field of X-ray spotting machines, can solve problems such as low spotting efficiency, poor pointing accuracy, and complex spotting machine structure, and achieves convenient operation, good versatility, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It should be understood that the embodiments described here are only used to explain the present invention, but not to limit the present invention.

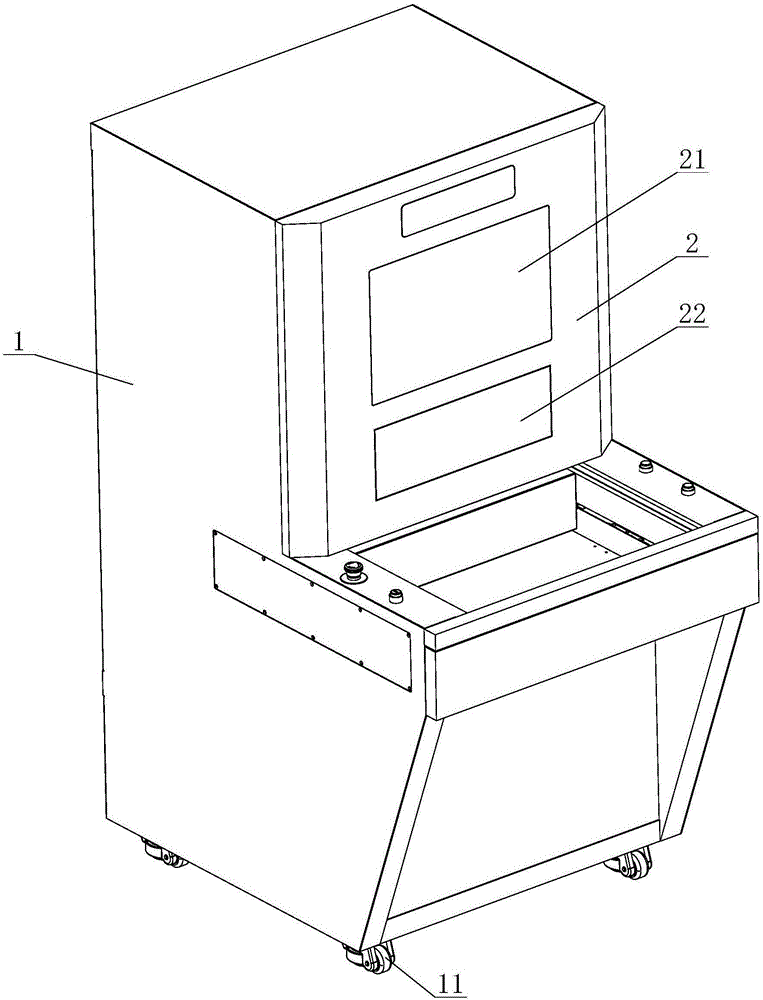

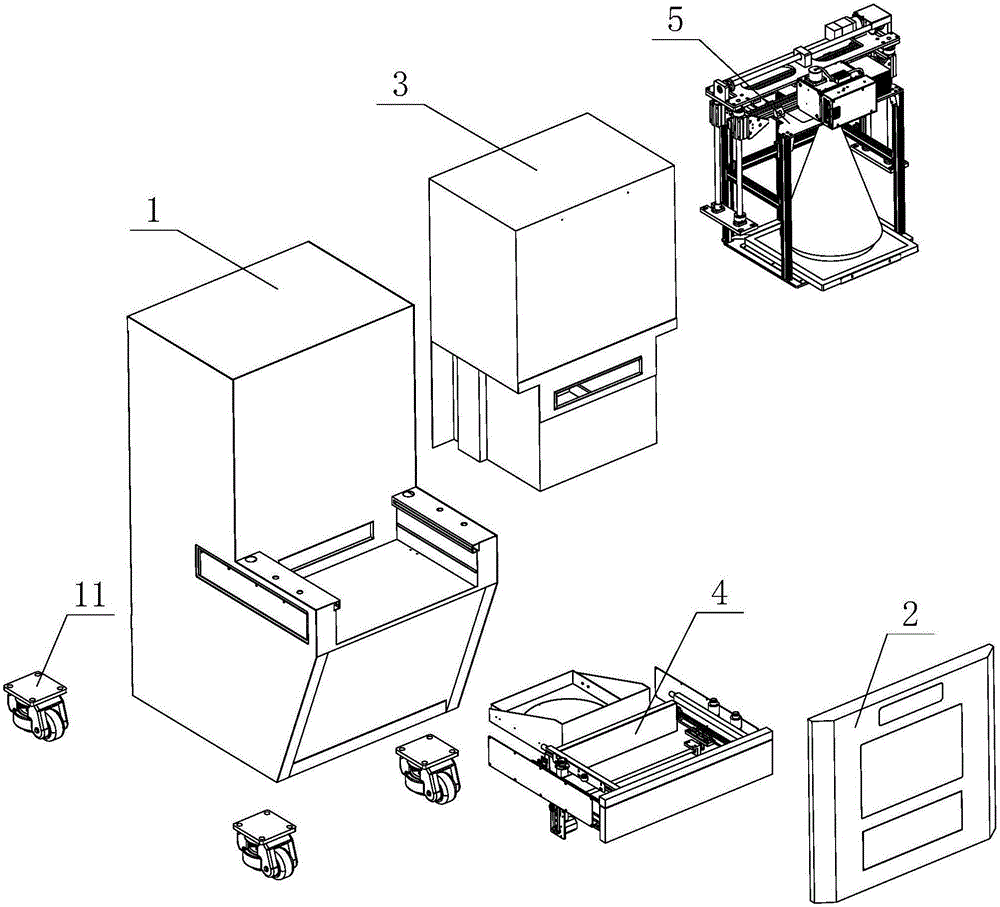

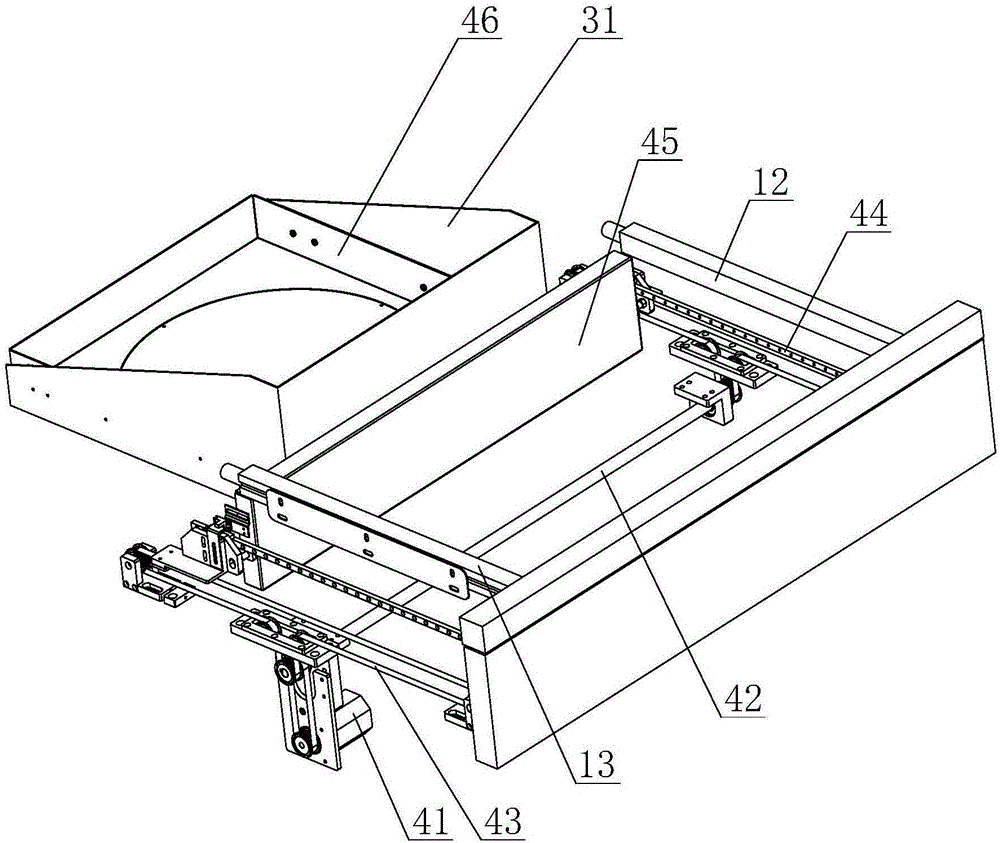

[0023] Please refer to Figure 1 to Figure 4 As shown, in this embodiment, an X-ray pointing machine includes a cabinet 1, the bottom of the cabinet 1 is provided with casters 11, the cabinet 1 is provided with a lead shielding room 3 and a controller, and the cabinet 1 is provided with There is a front panel 2, the front panel 2 is provided with a display 21, and a notch is provided on the front panel 2, a shaft is rotatably arranged in the notch, and a box body 22 is fixed on the shaft, and the slot The mouth is provided with a self-locking switch, the front end of the movable block of the self-locking switch is provided with a magnet, the box body 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com