Anti-short circuit transformer and preparation technology thereof

A transformer and anti-short-circuit technology, applied in the field of transformers, can solve the problems of winding instability and winding damage, and achieve the effect of preventing instability and deformation, small size and more profit space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

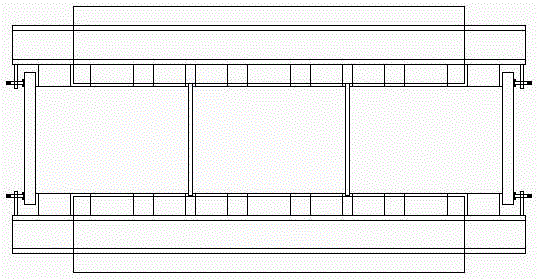

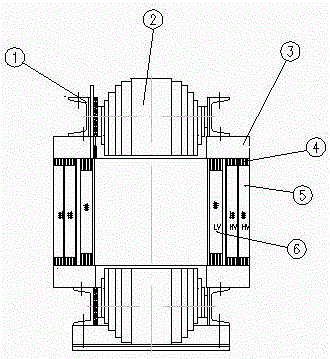

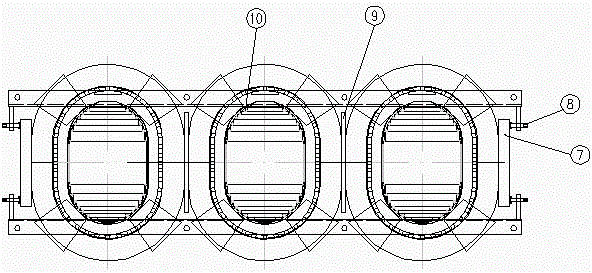

[0030] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes A-phase coils, B-phase coils, and C-phase coils. 1. The high-voltage coil 5 is set outside the iron core 2, and the inner insulating cardboard side of the low-voltage coil 6 is covered with a glue layer. This side of the inner insulating cardboard is in contact with the wires of the low-voltage coil 6. The interlayer insulation and terminal The ring 4 is all made of full-glue cable paper, the inner insulating cardboard, the low-voltage coil 5 wires, the interlayer insulation, and the end ring 4 are an integral structure. Dot glued paper, brush the glue layer on both sides of the end ring of the high-voltage coil 5, the wires of the high-voltage coil 5, the interlayer insulation, and the end ring form an integral structure, and set the pads 3 outside the end rings of the low-voltage coil 6 and high-voltage coil 5 in sequence , clip 1, low-voltage coil 6, high-voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com