A method for producing aluminum alloy airbag support arm with horizontal squeeze casting machine

A technology of squeeze casting machine and support arm, which is applied in the field of material forming of automobile aluminum alloy airbag support arm, can solve the problems of high machining cost, long machining time, complicated forging process, etc., and achieve low cost, high utilization rate, The effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

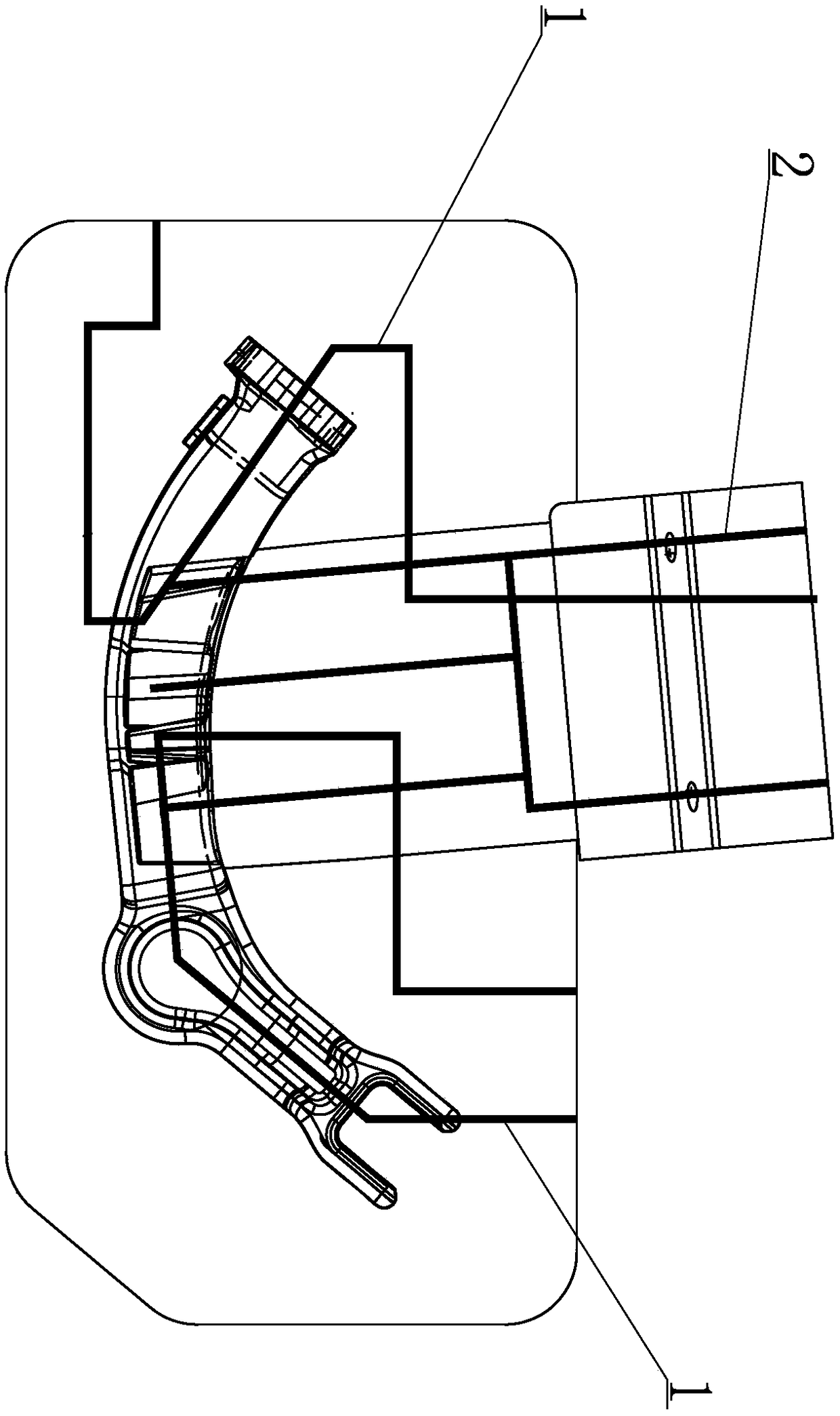

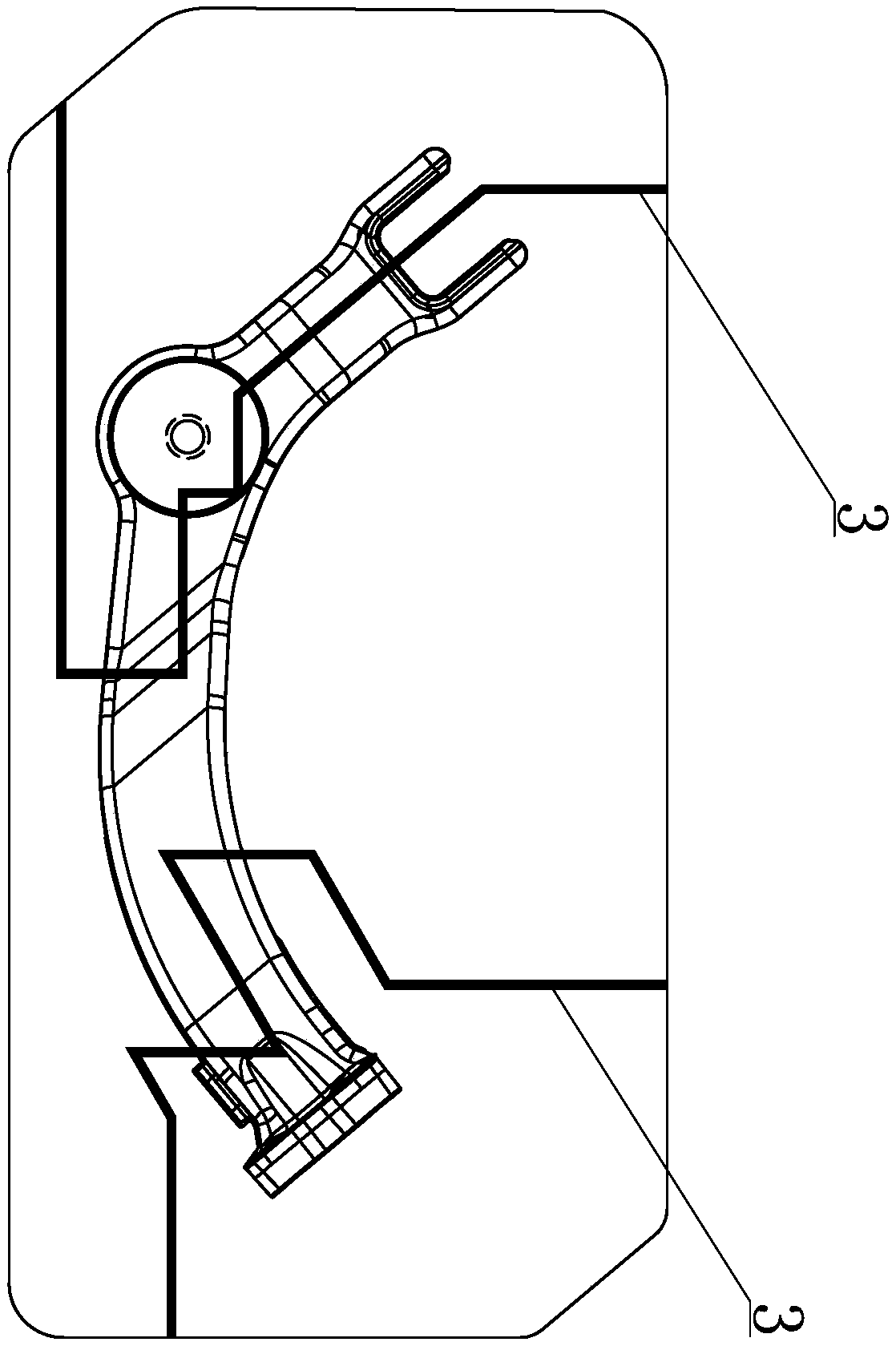

[0025] The following structural drawings describe the invention in further detail.

[0026] A method for producing an aluminum alloy airbag support arm with a horizontal squeeze casting machine, wherein the specific application is as follows:

[0027] (1) Mold pouring and overflow design

[0028] The flow state and pressure distribution of the liquid flow are used to realize the smooth filling and sequential solidification of the parts under pressure; the design of the ingate includes the position, shape and size of the ingate. The opening of the ingate should ensure that there are few or no pores and shrinkage defects inside the part; the appearance of the part should be free from cold insulation and the surface should be smooth and complete; the selection of the position of the ingate is the first issue to be considered in the design of the gating system; When designing the position of the inner gate, the structural shape, wall thickness, shrinkage deformation, alloy type, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com