Preparation method of artificial stone plate grains

A technology of artificial stone slabs and artificial stones, which is applied in the direction of copying/marking methods, patterns imitating natural patterns, special patterns, etc., which can solve the problems of difficult to stabilize and consistent texture effects, low degree of automation, and obvious artificial traces, so as to achieve easier control of quality , stable quality, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

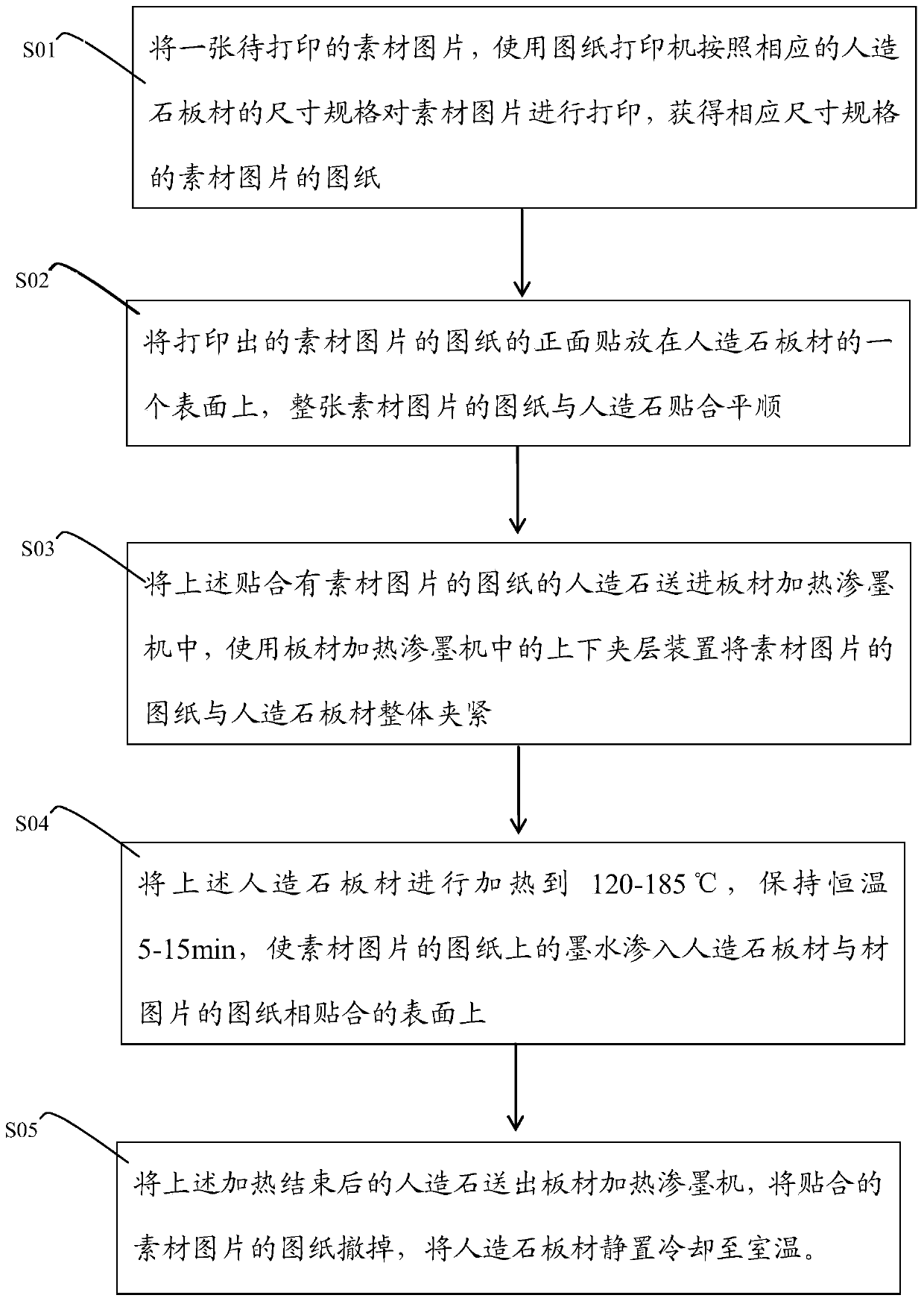

[0017] Please refer to figure 1 As shown, the present invention provides a kind of preparation method of artificial stone slab grain, comprises the following steps:

[0018] Step S01: Use a drawing printer to print a material picture to be printed according to the size specification of the corresponding artificial stone plate, and obtain a drawing of the material picture with the corresponding size specification;

[0019] In this step, the material picture to be printed can be taken by a digital camera or obtained by scanning natural stone with a scanner. The material picture is a high-pixel digital image, for example, the pixel can reach 2600DPI or above, so that the material picture more clearly. According to the actual texture needs, different natural stones can be selected to obtain material pictures. The dimensions and specifications of the corresponding artificial stone slabs can be set according to actual application occasions and requirements. In this embodiment, pr...

Embodiment 1

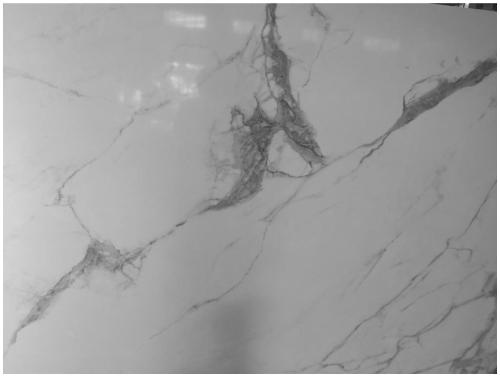

[0034] Print out the drawing of the material picture with a size of 3200*1600mm (length*width) using a drawing printer, prepare a 3200*1600*20mm (length*width*thick) artificial stone plate, and print the front side of the drawing of the material picture (that is, print Surface) Lay the polished surface of the plate for overall smooth paving without wrinkles, wherein the roughness of the polished surface is 65 μm, and then send it to the upper and lower interlayer device of the plate heating inking machine for clamping, and the upper and lower interlayer device The upper clamping device is heated to 160°C and maintained for 10 minutes, so that the ink on the drawing of the material picture penetrates into the surface of the artificial stone, and then the upper and lower clamping devices are released, and the artificial stone plate is withdrawn from the upper and lower interlayer devices. The drawing of the material picture, the pattern on the drawing of the material picture has ...

Embodiment 2

[0036] Print out the drawing of the material picture with a size of 3200*1600mm (length*width) using a drawing printer, prepare a 2600*1200*25mm (length*width*thick) artificial stone plate, and paste the front side of the drawing (ie the printing surface) The polished surface of the plywood is paved smoothly and wrinkle-free as a whole, and the roughness of the polished surface is 45 μm. Cut the drawing of the material picture so that the size specification is 2600*1200 and the edge is completely aligned with the edge of the artificial stone plate; Then send it to the upper and lower interlayer devices of the plate heating ink penetration machine for clamping, heat the upper clamping device in the upper and lower interlayer devices to 180°C, and keep it for 15 minutes to make the ink on the drawing of the material picture penetrate into the surface of the artificial stone plate Then loosen the clamping device of the upper and lower layers, withdraw the plate from the clamping d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com