Maintenance work platform

A work platform and maintenance work technology, applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problem that the working height, load capacity, external dimension, working range, and functional safety protection of the lifting work platform cannot meet the use requirements and safety requirements. and other problems, to achieve the effect of meeting the requirements of maintenance operations, easy to use and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

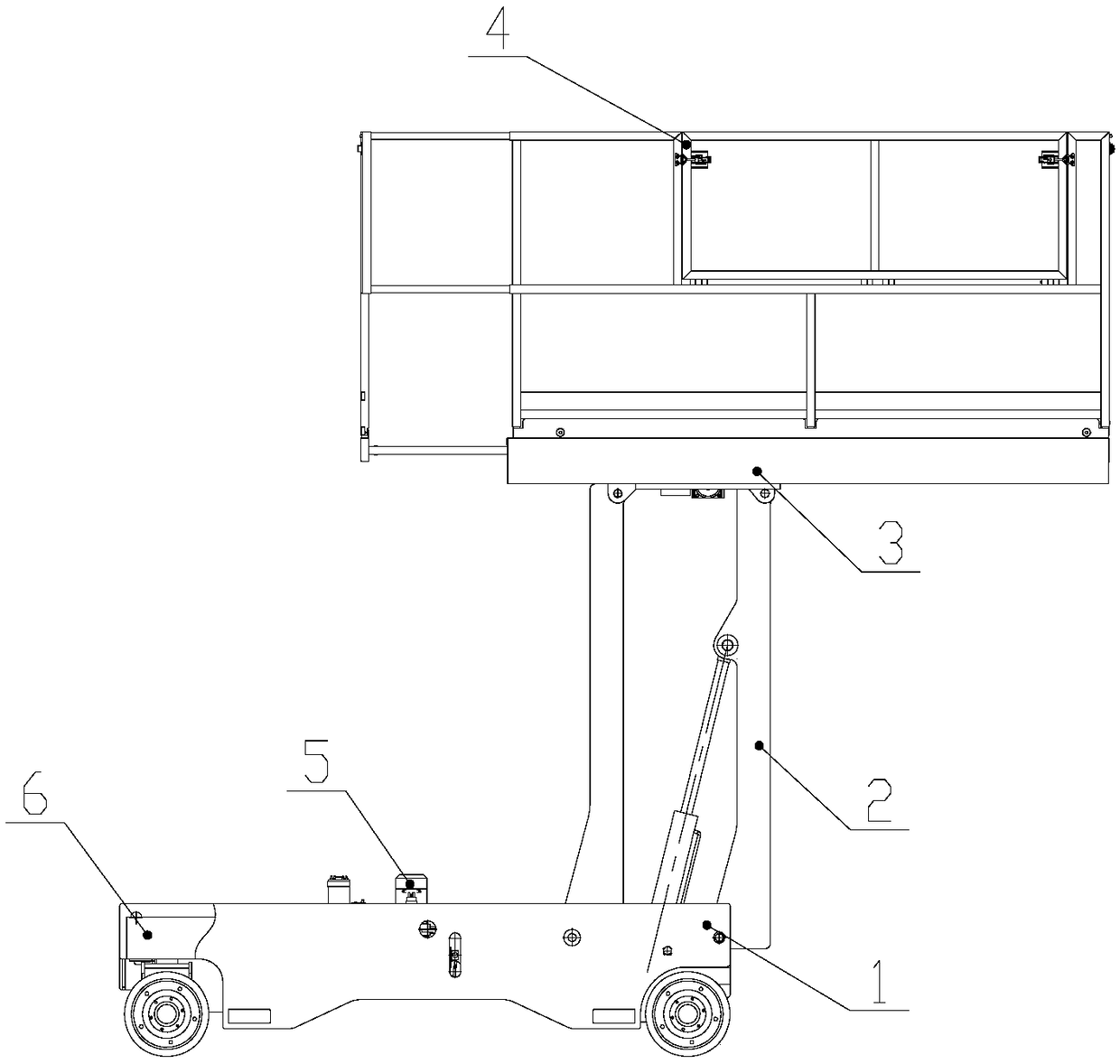

[0020] refer to Figure 1-3 . A working platform for machine maintenance, which mainly includes a lifting drive mechanism 2 assembled on one side of the chassis assembly 1 in the longitudinal direction, a working platform 3 fixedly connected to the free end of the lifting driving mechanism 2, and set on the box body of the working platform 3 The guardrail assembly 4, and the hydraulic system 5 and the electrical control system 6 arranged in the box of the chassis assembly 1.

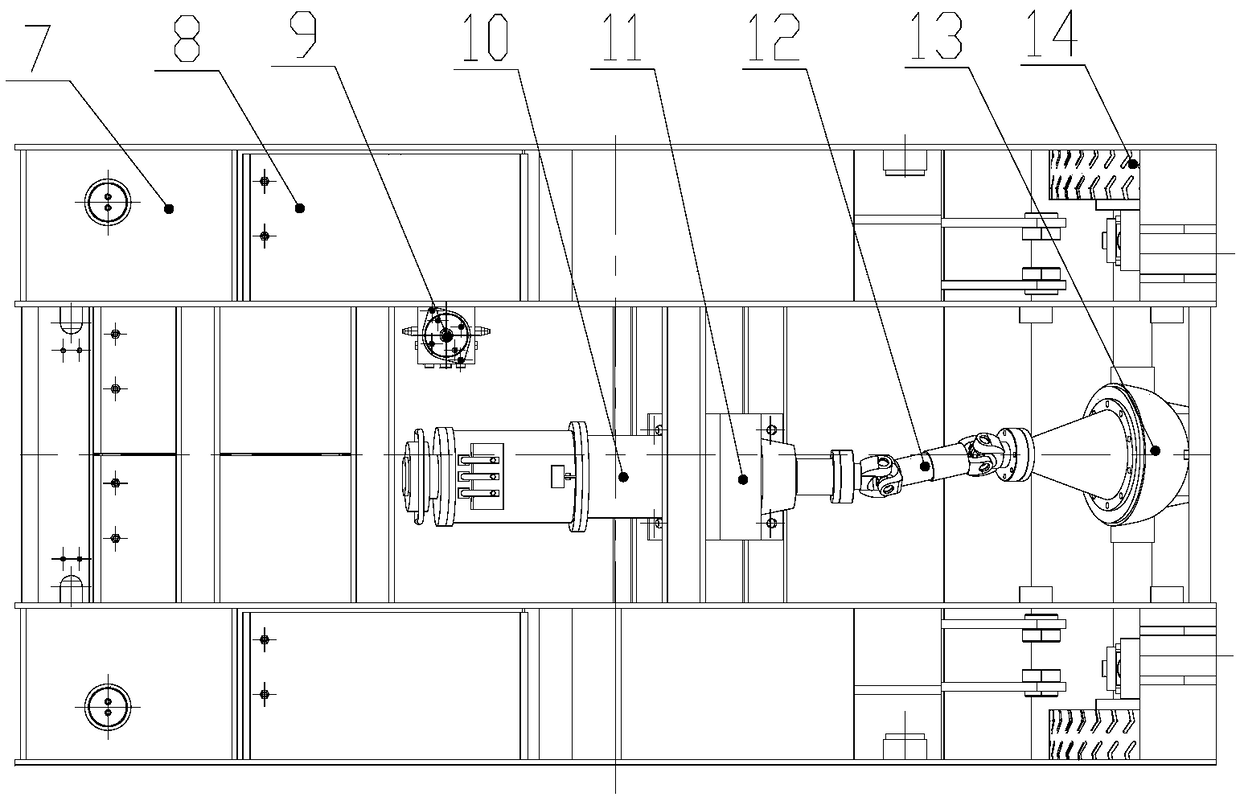

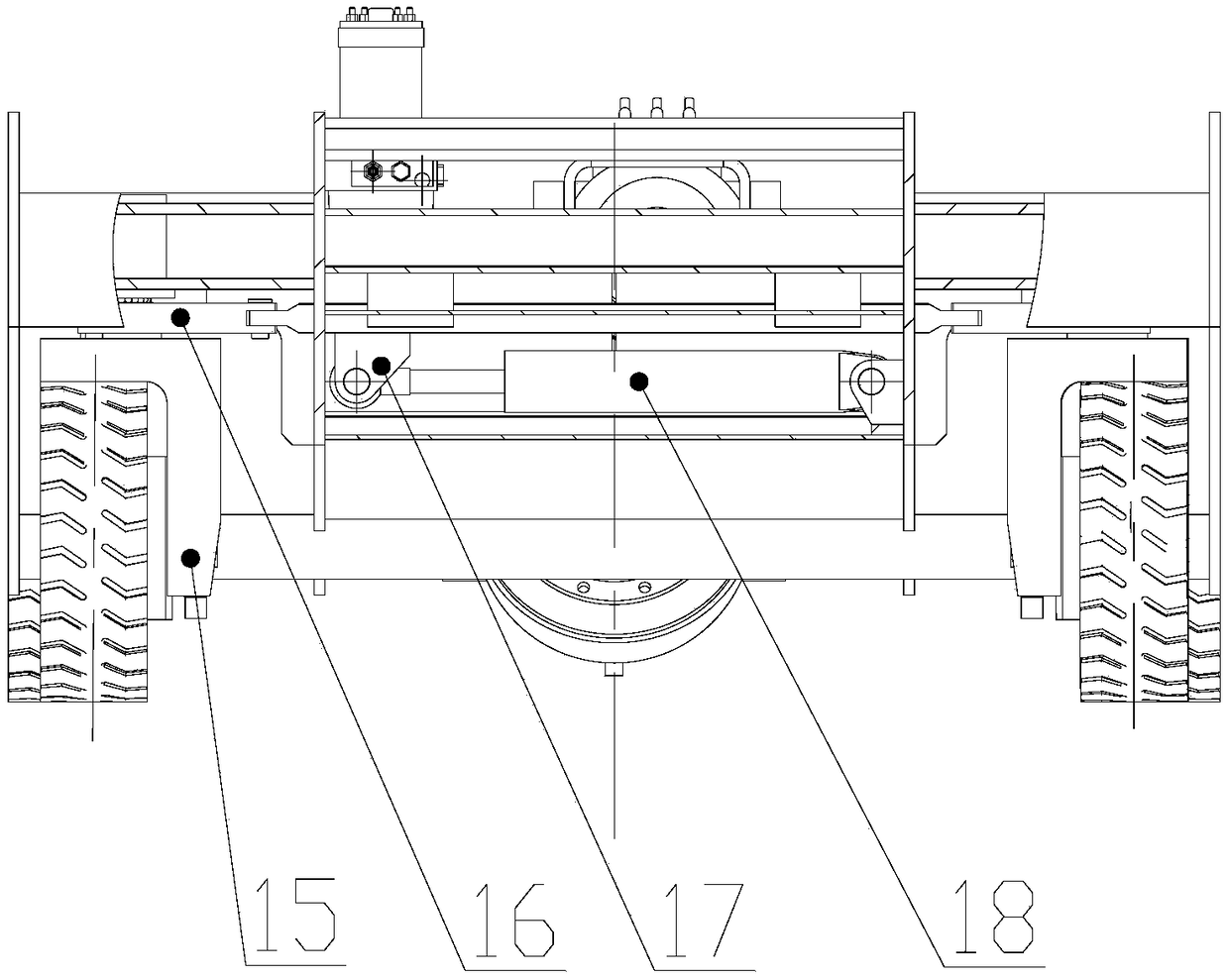

[0021] exist figure 2 with image 3 In the chassis assembly 1 shown, the main structural member of the chassis assembly 1 is a chassis frame 7 welded by steel plates and section steel, and the chassis frame 7 is also the installation base of the lifting drive mechanism 2 .

[0022] The battery pack 8 arranged on the chassis assembly 1 is used as a power source for driving the product to walk, hydraulically assisted steering, hydraulically driven lifting and moving of the working platform.

[0023] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com