Ceramic chip leveling heat treatment tool and heat treatment process thereof

A technology of heat treatment furnace and sheet, which is applied in the field of sheet ceramic flattening heat treatment tooling and heat treatment process, can solve the problems of lower product yield, affect product qualification rate and production cycle, waste of resources, etc., and achieve the goal of improving product qualification rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

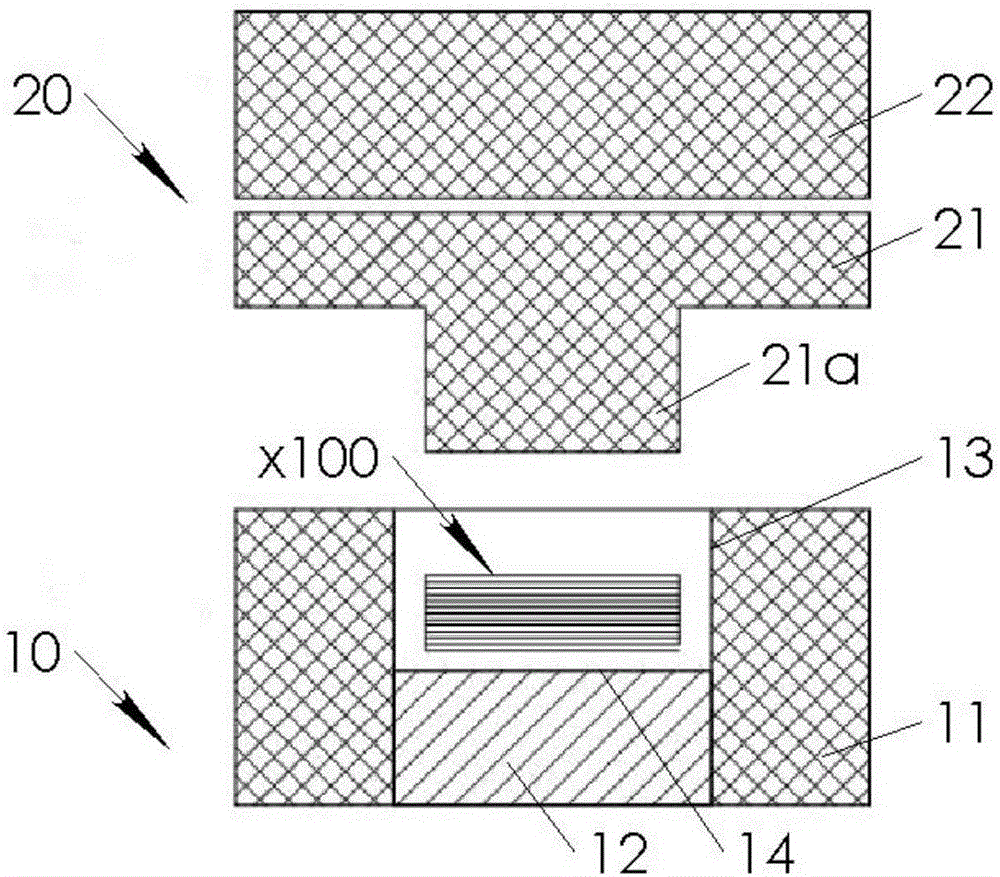

[0028] Such as figure 1 As shown, a kind of flattening heat treatment tooling for sheet-shaped ceramics proposed in Embodiment 1 of the present invention includes:

[0029] 10 heat treatment accommodating groove, the top opening of the heat treatment accommodating groove is used to place stacked sheet ceramic X100 to be flattened;

[0030] 20. The pressing cover for heat treatment, the outer contour dimension of the lower end surface of the pressing cover is less than or equal to the outer contour dimension of the top opening of the accommodating groove 10 for heat treatment, which is used to extend into the opening of the accommodating groove and press the Describe the planarized ceramic sheet X100.

[0031] Wherein, the depth inside the accommodating groove is determined according to the height of the sintered sheet-like ceramics to be flattened after stacking, and the depth inside the accommodating groove is greater than the height of the layered sintered sheet-like cerami...

Embodiment 2

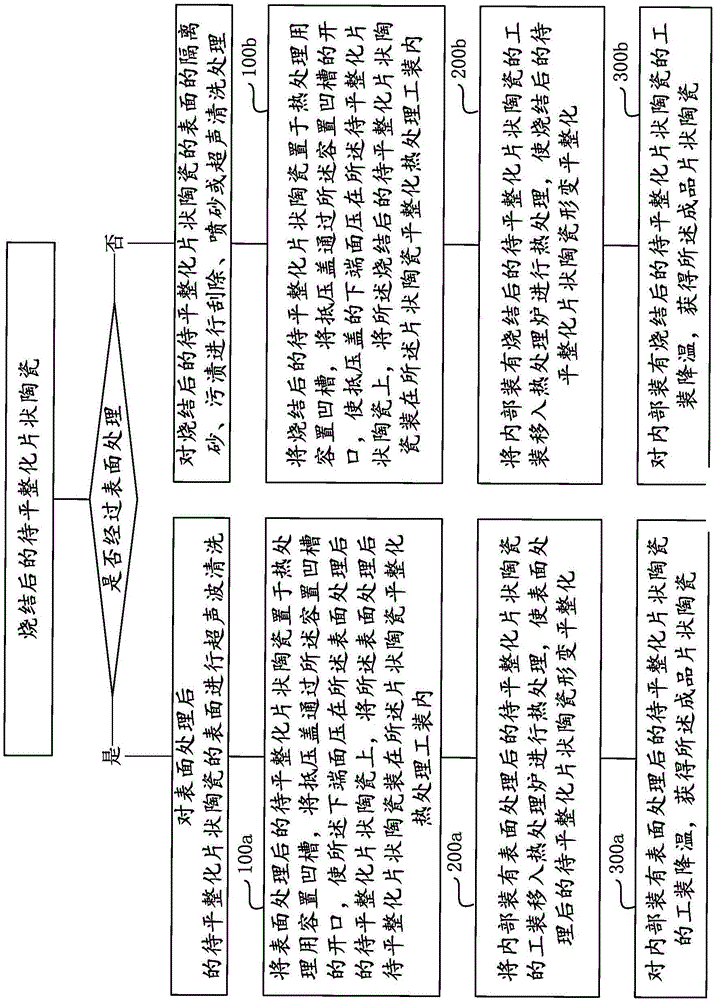

[0040] Embodiment 2 of the present invention provides a flattening heat treatment process for warped and deformed sheet ceramics after surface treatment. The flattening heat treatment tool for sheet ceramics can directly adopt the flattening heat treatment tool for sheet ceramics provided in the first embodiment above. For the specific implementation structure, please refer to the relevant content described in the first embodiment above, and will not repeat them here. The flattening heat treatment process of the sheet-shaped ceramics is used to flatten and heat-treat the surface-treated sheet-shaped ceramics to be flattened into finished sheet-shaped ceramics, wherein the surface treatment specifically includes the following situations, 1. For sintering Carry out one-sided grinding treatment to the sheet-shaped ceramics after sintering (form the sheet-shaped ceramics that carries out single-sided grinding treatment to the sintered sheet-shaped ceramics); 2, carry out double-sid...

Embodiment 3

[0065] Embodiment 3 of the present invention provides a flattening heat treatment process for sheet ceramics aimed at warping and deformation after sintering. Compared with the flattening heat treatment process for sheet ceramics described in Embodiment 2 above, the sintered sheet Shaped ceramics are not processed by grinding and polishing, and are sheet ceramic blanks after sintering. The warpage of the sheet ceramics to be flattened after this sintering is larger than that of the surface treated sheet ceramics to be flattened in Example 2 ; The flattening heat treatment tooling of the sheet-shaped ceramics described in the third embodiment can directly adopt the flattening heat treatment tooling of the sheet-shaped ceramics provided in the first embodiment above, and the specific realization structure can refer to the related content described in the first embodiment above , which will not be repeated here. The flattening heat treatment process of the sheet-shaped ceramics i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com