High-polymer grouting reinforcement anti-settlement widened roadbed

A high-polymer, anti-settlement technology, applied in the direction of roads, roads, infrastructure engineering, etc., can solve the problems of slope slump, lateral slip of roadbed, etc., to achieve less slump, effective slope protection, stable joint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

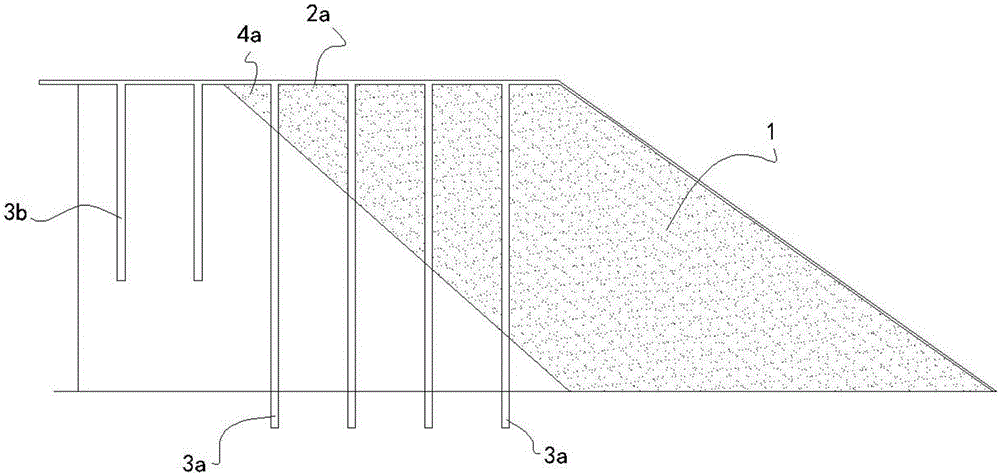

[0039] The high polymer grouting in this embodiment to strengthen the subsidence and widen the subgrade is implemented for the low embankment, and the low embankment refers to the embankment whose height is not greater than 1.5m.

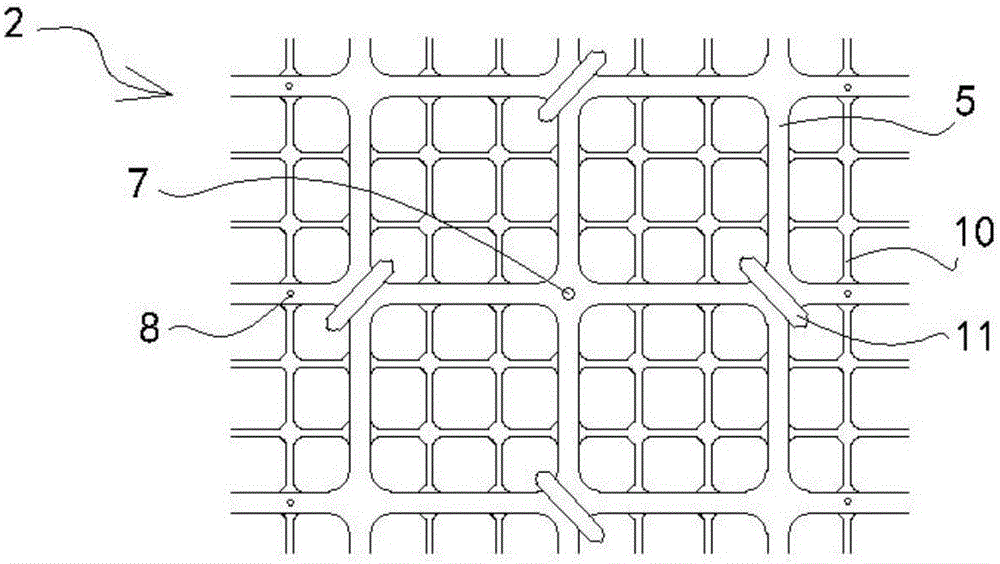

[0040] Such as figure 1 As shown, for the low embankment, the interface between the old subgrade and the new subgrade is set as the slope interface 4a, the filling layer 1 is filled and compacted in layers according to the height of the embankment, and the geotechnical pipe network is laid on the top surface of the filling layer 1; The geotechnical pipe network is formed by grouting with polymer slurry to form the geotechnical pipe network 2a for grouting the filling layer, and the vertical filling layer reinforcement column 3a that penetrates the slope interface 4a and extends into the foundation; There is a road shoulder geotechnical pipe network extending on the subgrade, and the road shoulder geotechnical pipe network is formed by grouting with ...

Embodiment 2

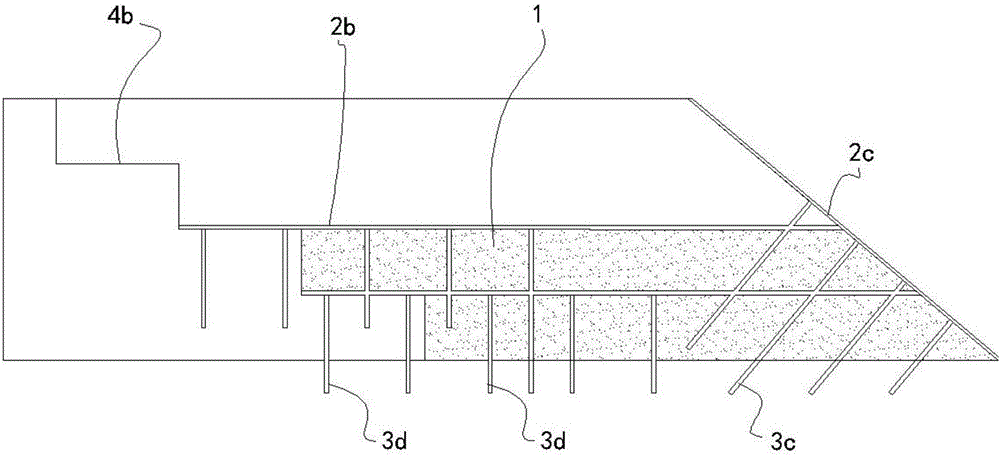

[0050] In this embodiment, polymer grouting to reinforce anti-subsidence and widen the subgrade is aimed at general embankments or high embankments. General embankments refer to embankments whose height is between 1.5m and 18m, and high embankments refer to embankments whose height is not less than 18m.

[0051] Such as figure 2 As shown, for general embankment or high embankment: the interface between the old subgrade and the new subgrade is set as the step interface 4b, and the filling layer 1 is filled and compacted in layers according to the height of the corresponding step in the step interface 4b, forming various The filling layer is layered, and the geotechnical pipe network is laid on the top surface of each layer of filling layer and extended to the top surface of the corresponding layer of steps to form an interlayer geotechnical pipe network; for the interlayer geotechnical pipe network, the high polymer slurry is injected The grout forms the interlayer grouting ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com