Rotary locking element

A technology of rotating locking and locking disks, applied in the direction of fixtures, mechanical equipment, etc., can solve the problems of damage to the locking disk equipment, difficult to ensure the consistency of the locking disk, easy to scratch with peripheral equipment, etc., to achieve convenient operation, avoid connection difficulties, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further elucidated below in conjunction with this embodiment.

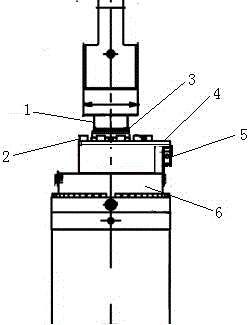

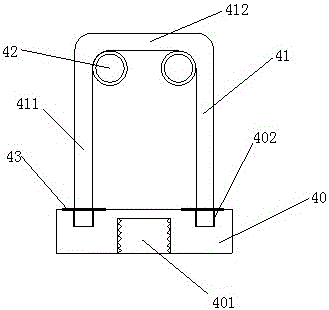

[0015] The present invention provides a rotary locking piece, which includes a rotary locking disc 40, a U-shaped cylindrical steel 41 and two sets of bolts 42. The rotary locking disc 40 is provided with a positioning groove 401 connected with a rotating body, and around the positioning slot 401 is provided with a socket Groove 402, the U-shaped cylindrical steel is integrally formed by a horizontal bar 411 and two vertical bars 412, and the nut of the bolt is welded on the inner side of the corner where the parallel bar and the vertical bar are connected. The bolt is used for the U-shaped cylindrical steel 41 and the servomotor For the connection between the bodies, the two vertical rods of U-shaped cylindrical steel are inserted into the insertion groove 402 of the rotating locking disk, and the lower end of the vertical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com