Positioning and lubrication sealing structure of bogie-suspension bearing gear box

A sealing structure and gear box technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problem of bearing gear box bearing positioning and lubrication and sealing structure inconclusive, to improve maintainability performance, improved reliability and service life, and the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

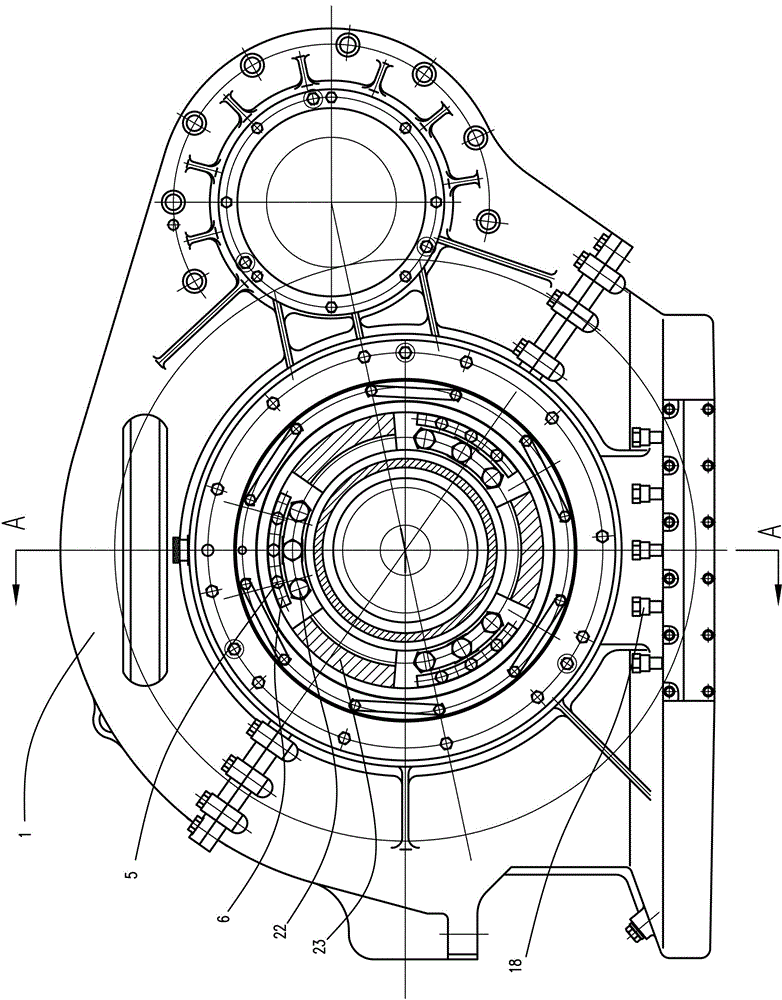

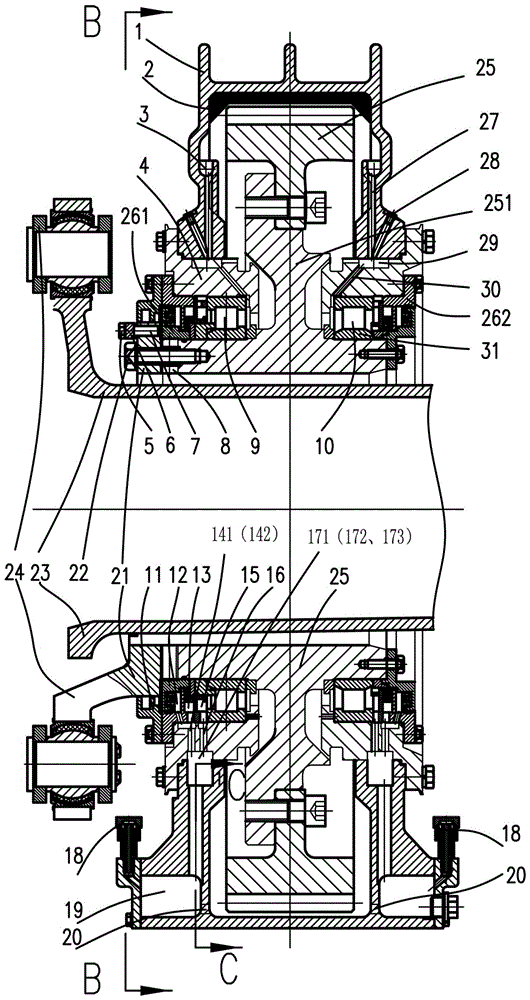

[0023] Such as figure 1 , figure 2 As shown, an embodiment of the positioning, lubrication and sealing structure of the suspension bearing gearbox bearing of the present invention includes a gear box 1 with a six-bar linkage hollow shaft 23 installed in the middle, and a six-bar linkage hollow shaft located in the gear box 1 23 is connected to the large gear core 251 of the installation large gear 25 through the end tooth drive plate 21 and six connecting rods (add rubber joint) 24, and the hollow shaft 23 of the six connecting rod mechanism is connected with the wheel through the six connecting rods to realize the transmission of gear torque.

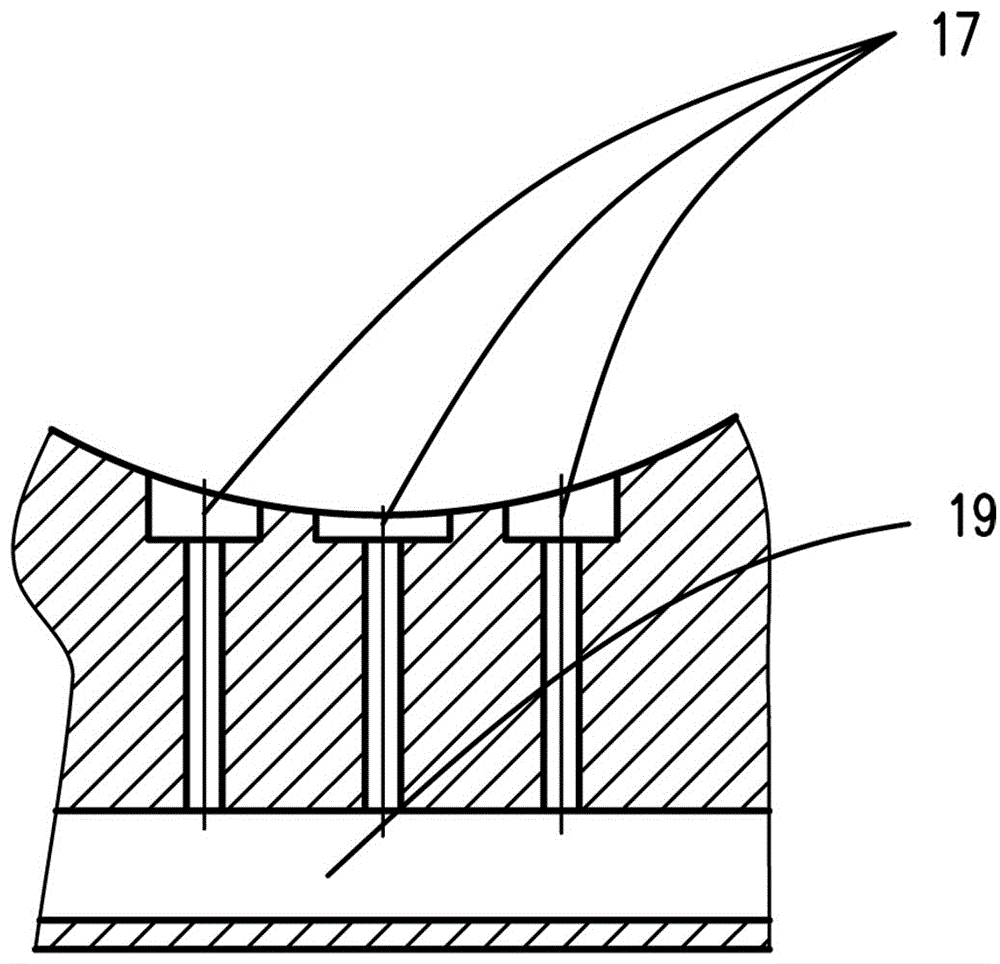

[0024] Two ends of the large gear core 251 are respectively supported on the bearing seat 4 installed on the gear case 1 through the first cylindrical bearing 9 and the second cylindrical bearing 10 . The inner ring of the outer end surface of the end tooth transmission disc 21 is provided with a first threaded hole, and the end toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com