Gas conveying pipeline metering and pressure adjusting device and method

A technology for metering pressure regulation and gas transmission pipelines, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., and can solve the problems of increasing safety hazards and maintenance workload, prone to ice blockage, slow flow control response time, etc. problems, to achieve the effect of facilitating remote detection and control, real-time detection and control, and facilitating maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

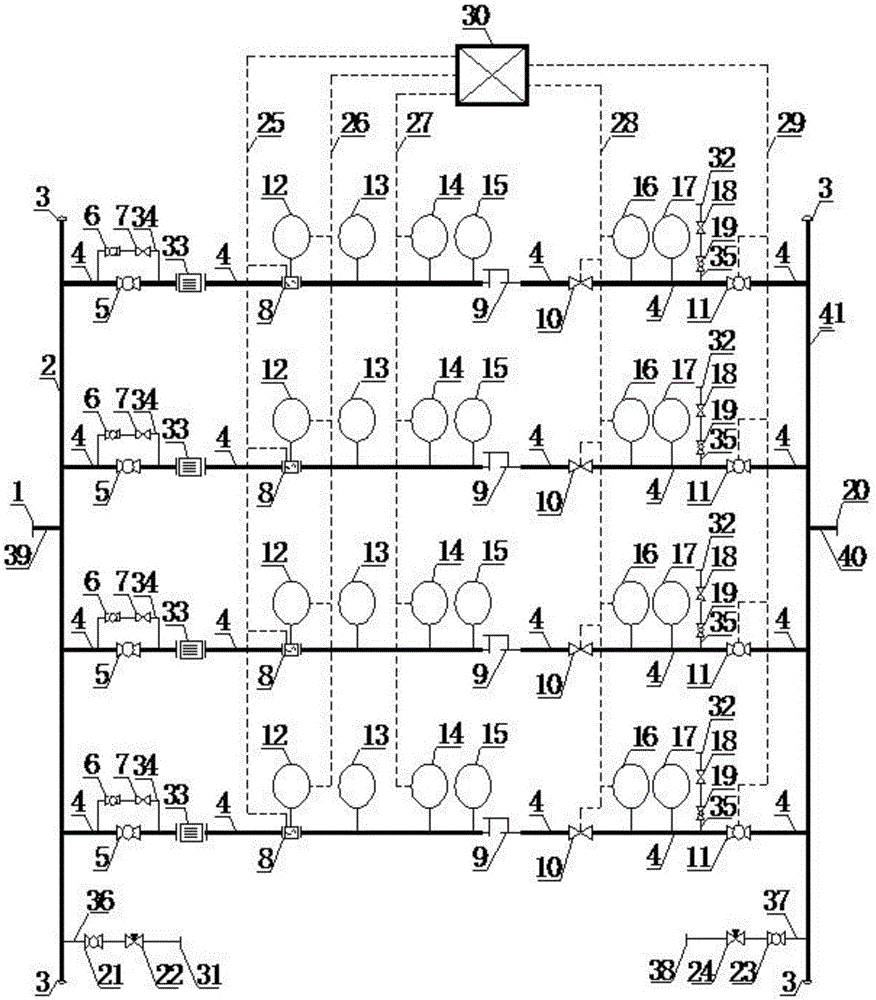

[0038] Example 1, such as figure 1 As shown, a gas pipeline metering and pressure regulating device described in an embodiment of the present invention includes: a first flange 1, a second flange 20, a first process pipeline 39, a second process pipeline 40, a first manifold 2. The second manifold 41 , the pipe cap 3 , the multi-channel pressure flow control device and the instrument junction box 30 .

[0039] One end of the first process pipeline 39 is connected to the first flange 1, the other end of the first process pipeline 39 is connected to the first manifold 2, one end of the second process pipeline 40 is connected to the second flange 20, and the other end of the second process pipeline 40 is It is connected with the second manifold 41 , both ends of the first manifold 2 and the second manifold 41 are connected with the cap 3 , and four pressure flow control devices are arranged between the first process pipeline 39 and the second process pipeline 40 .

[0040] The f...

Embodiment 2

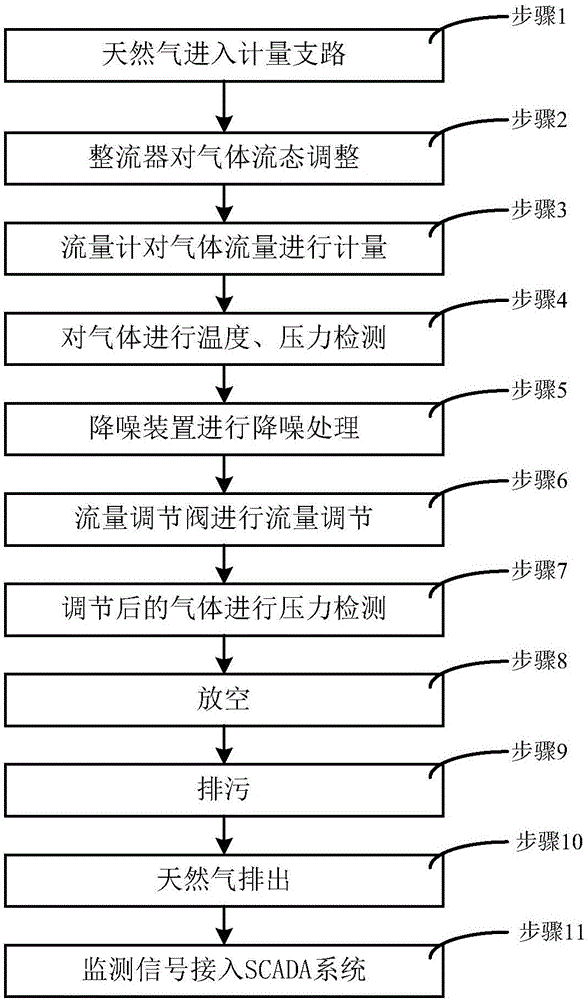

[0052] Example 2, such as figure 2 As shown, the present invention also provides a gas pipeline metering and pressure regulating method, which specifically includes the following steps:

[0053] Step 1, natural gas enters the first manifold 2 of the inlet, and enters the metering branch pipeline 4 through the first process valve 5 imported upstream;

[0054] Step 2, adjust the gas flow state through the rectifier 33;

[0055] Step 3, flow metering of gas by flowmeter 8;

[0056] Step 4, through the first intelligent pressure transmitter 12, the local thermometer 13, the integrated temperature transmitter 14 and the first local pressure gauge 15 to detect the temperature and pressure of the gas;

[0057] Step 5, performing noise reduction processing on the gas through the noise reduction device 9;

[0058] Step 6, adjusting the flow rate of the gas through the flow regulating valve 10;

[0059] Step 7, through the second intelligent pressure transmitter 16 and the second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com