Measuring device for measuring surface tension of high-temperature melt by adopting hanging drop method

A surface tension, high temperature melt technology, applied in the direction of measurement device, surface tension analysis, surface/boundary effect, etc., can solve the problem of inability to realize melt surface tension, and achieve the effect of reliable data, simple operation and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

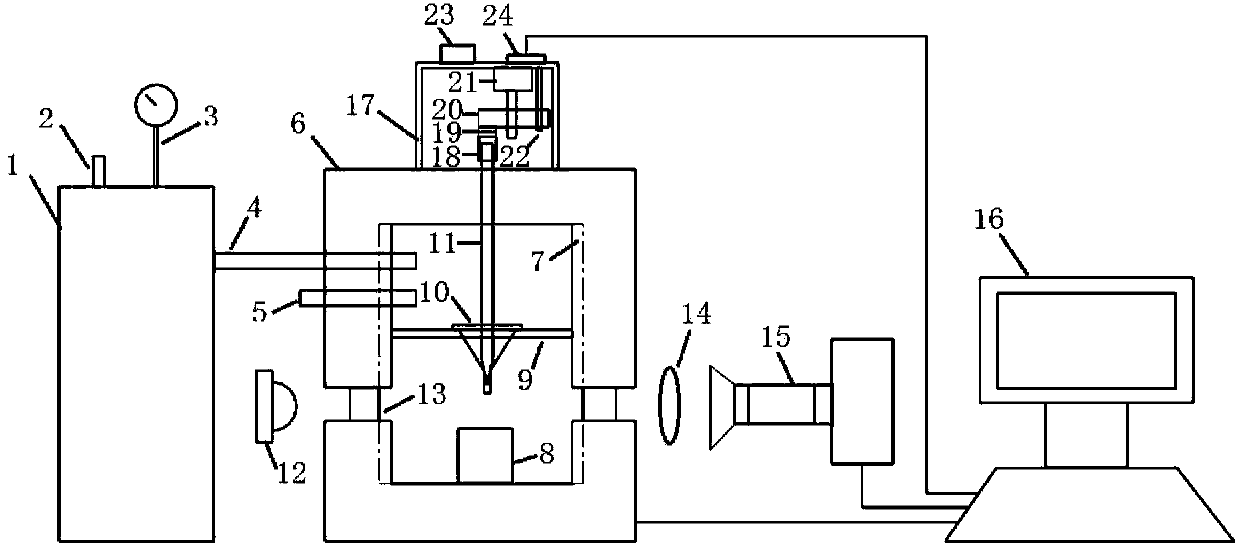

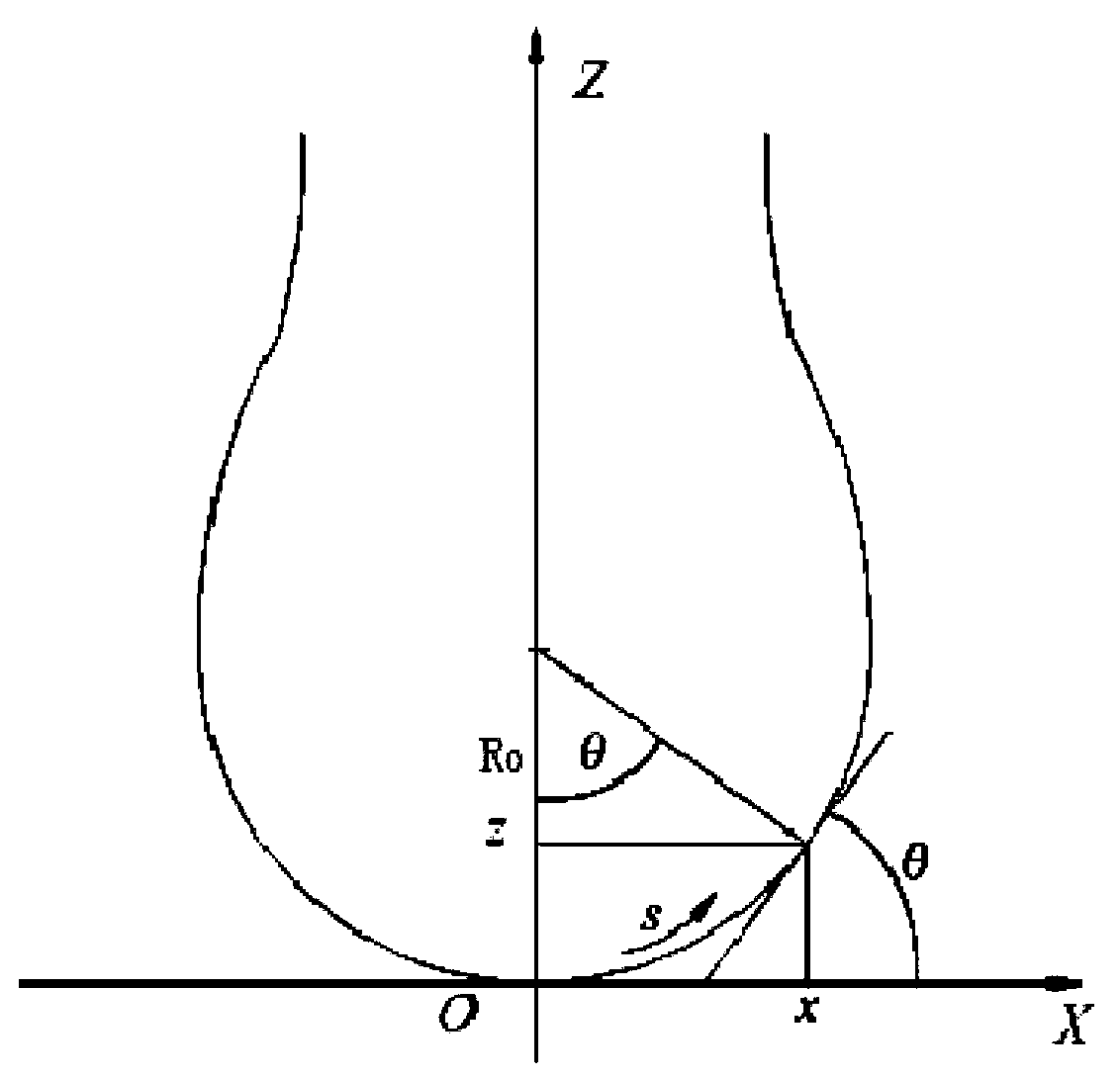

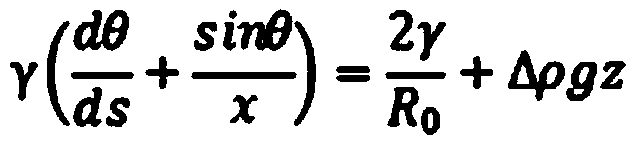

[0025] Aiming at various defects existing in measuring the surface tension of high-temperature melt in the prior art. The invention provides a measuring device for measuring the surface tension of a high-temperature melt by a pendant drop method, comprising a high-temperature heating furnace, a pendant drop forming device, a motor control device, an image capturing device, and a computer. The heating furnace is used to provide a high temperature environment to melt the solid sample into a liquid; the pendant drop forming device is set in the heating furnace to hold the sample and form the melt pendant drop; the motor control device is used to control the melt pendant drop; image shooting The device is used to observe and shoot the hanging drop of the melt, and the computer is used to process the image of the hanging drop to calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com