Engine ignition capacitor aging test fault detection device

A fault detection and ignition device technology, applied in capacitor testing, measuring devices, instruments, etc., can solve the problems of unstable sampling, failure to work, and difficulty, and achieve stable, accurate and reliable sampling, eliminate interference, and a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

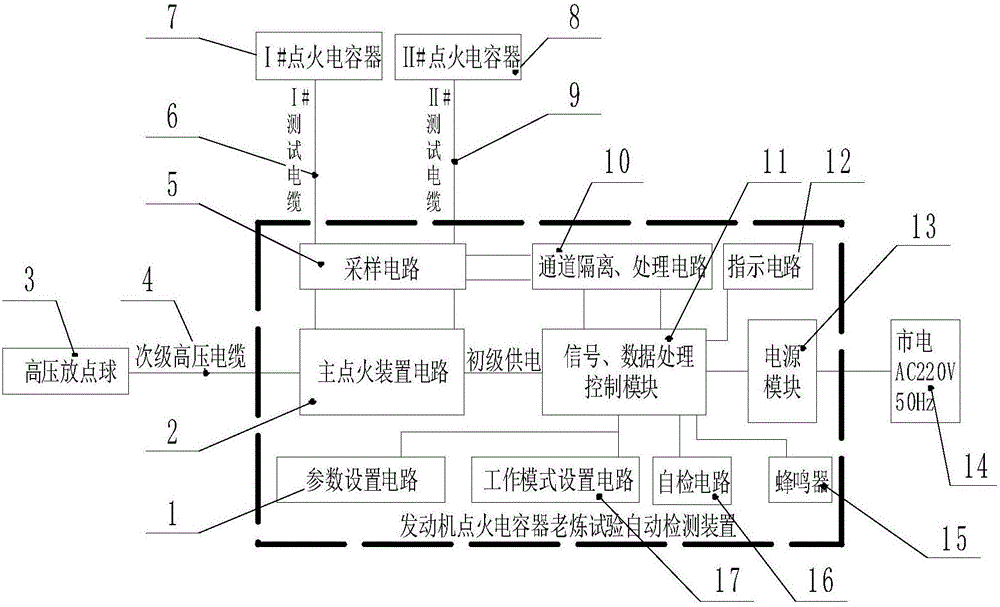

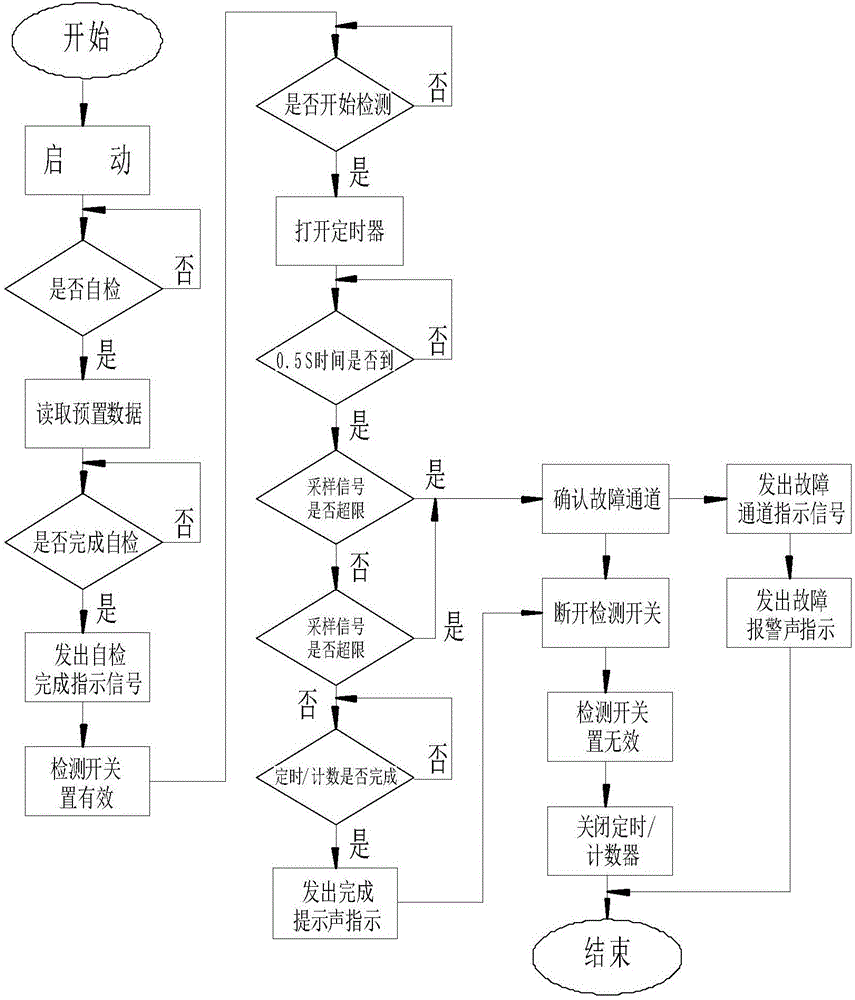

[0016] refer to figure 1 . In a preferred embodiment described below, a kind of engine ignition capacitor burn-in test fault detection device comprises: connect the main igniter circuit 2, power supply module 13 that puts the penalty ball by secondary high voltage cable, and pass test cable The matching ignition capacitors under test that are electrically connected to the main ignition device circuit 2 are respectively introduced, and the detection device is equipped with circuits such as sampling, channel isolation processing, signal and data processing control, working mode setting, parameter setting, and self-testing. The main ignition device circuit 2 is connected to the tested ignition capacitor through the sampling circuit 5, and the sampling circuit is electrically connected to the signal data processing control module 11 through the channel isolation processing control circuit 10, the main ignition device circuit 2, the parameter setting circuit 1, the working mode set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com