Nano LiBH4-SiO2 solid electrolyte and preparation method thereof

A solid electrolyte, nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of electrochemical devices not working at high temperatures, low battery safety and service life, and fossil fuels. Pollution and other problems, to achieve the effect of easy implementation, convenient synthesis, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

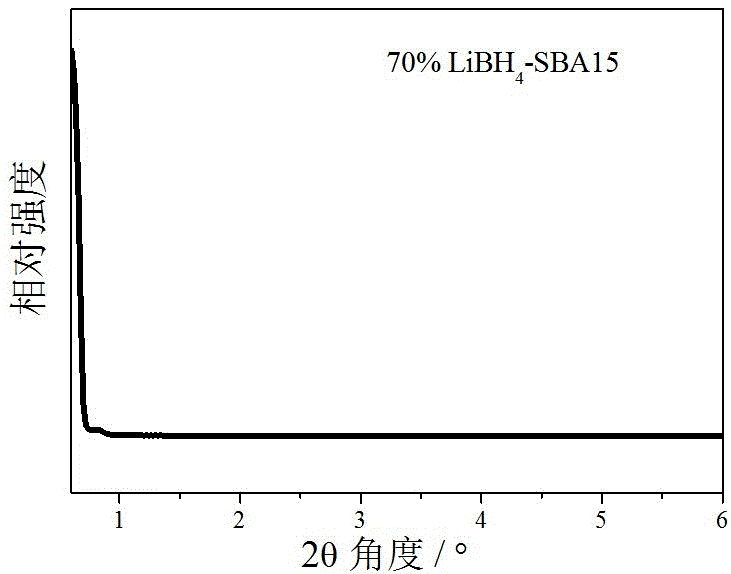

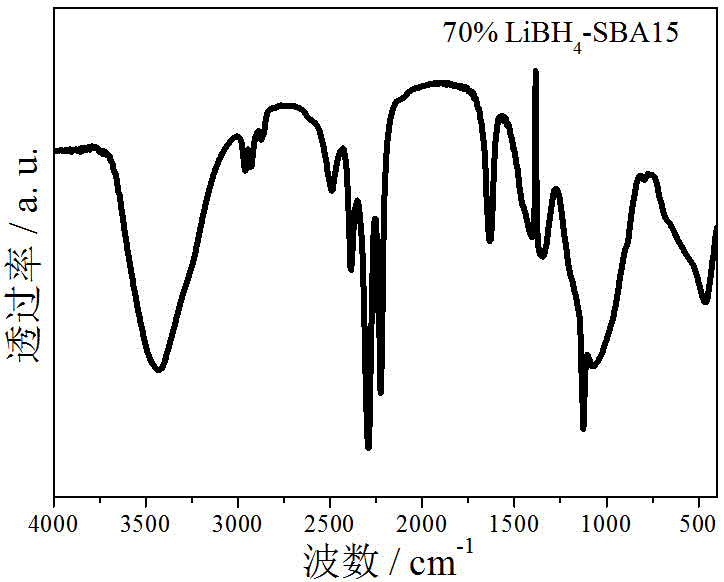

[0029] 1. Nano-LiBH with 70% loading 4 - Preparation of SBA15

[0030] First, the commercialized SBA15 was vacuum dehydrated at 500 °C for 6 h at a heating rate of 6 °C / min.

[0031] In a nitrogen glove box, mix 65 mg of anhydrous SBA15 with 1 mL (2 mol / L) of n-butyllithium cyclohexane solution, add hydrogen to 30 bar, and react at 150 degrees Celsius for 24 hours. In a nitrogen glove box, take the LiBH 4 and anhydrous zinc chloride in a ball mill tank (material ratio is 4), ball to material ratio (50), speed (35) ball mill for 3.5 h.

[0032] Mesoporous SiO 2 The loaded nano-lithium hydride and boronating agent were placed in different reaction flasks of the same autoclave, and under the protection of nitrogen atmosphere, the temperature was raised to 150°C at a rate of 5°C / min, and the boronation reaction was carried out for 48 hours to obtain mesoporous SiO 2 Loaded nano-LiBH 4 , recorded as 0.7-LiBH 4 -J.

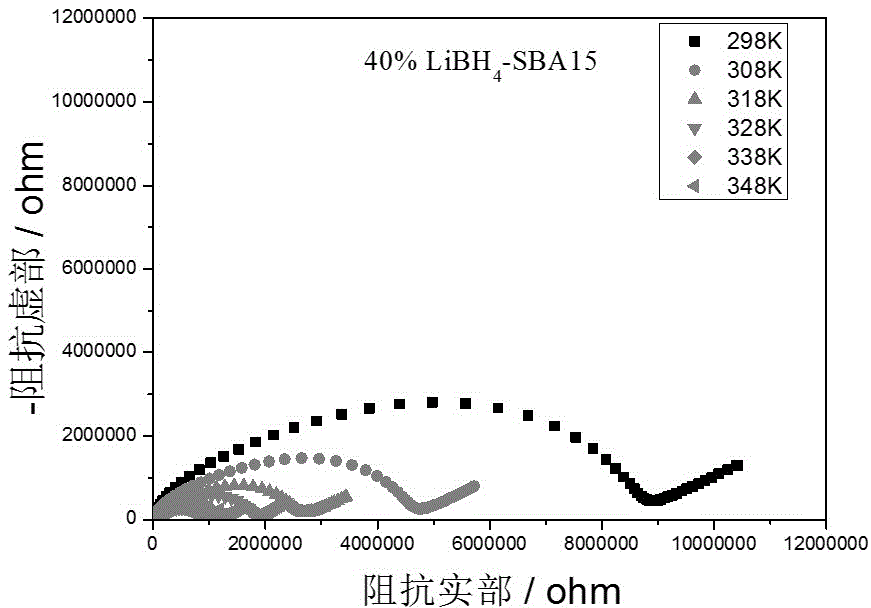

[0033] 2. 40% Nano LiBH 4 - Preparation of SBA15

[0034]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap