thresher

The technology of a thresher and a threshing roller is applied in the field of agricultural machinery, which can solve the problems of high labor intensity and troublesome straw handling, and achieve the effect of reducing labor intensity, improving labor efficiency and good threshing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

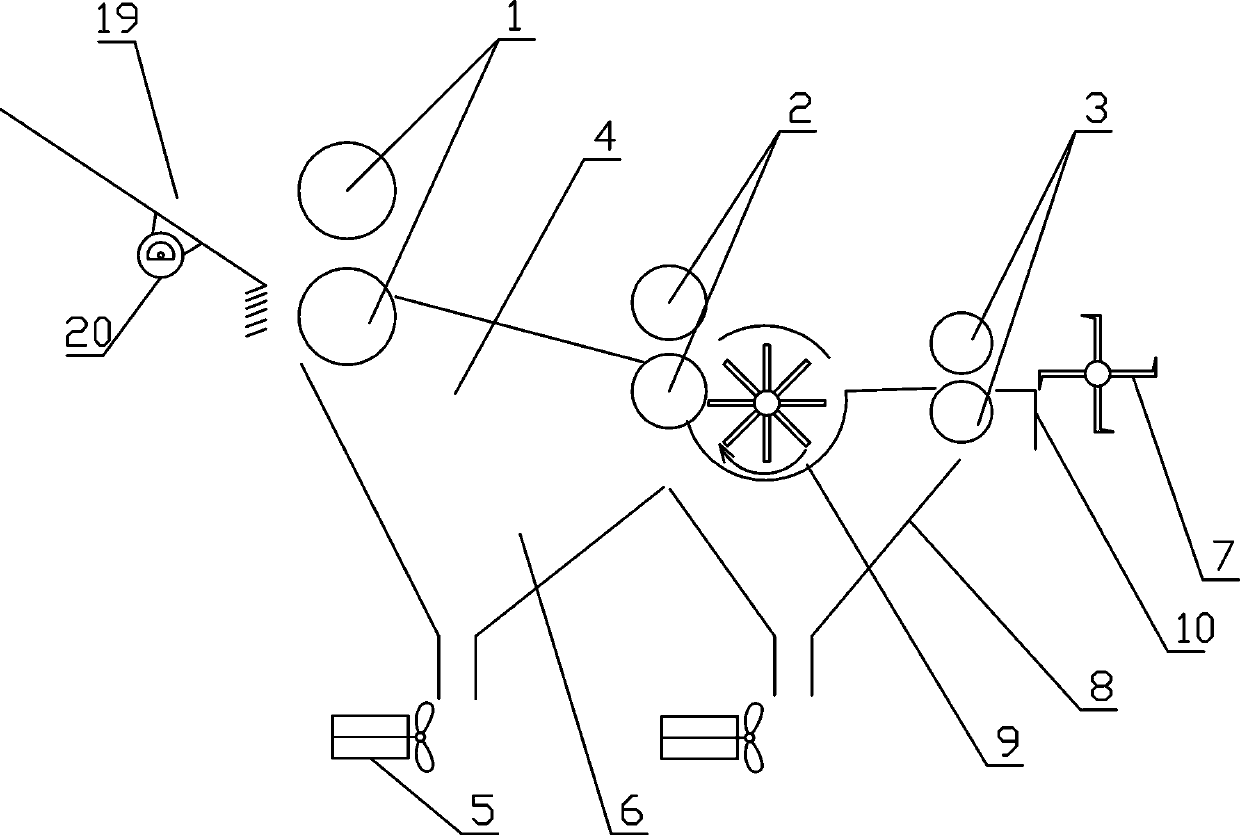

[0031] The front and rear orientations in this example are based on the running direction of the crops, with figure 1 For example, the direction of the feeding hopper is the front, that is, the left side in the figure, and the direction where the cutter roller is located is the rear, that is, the right side in the figure.

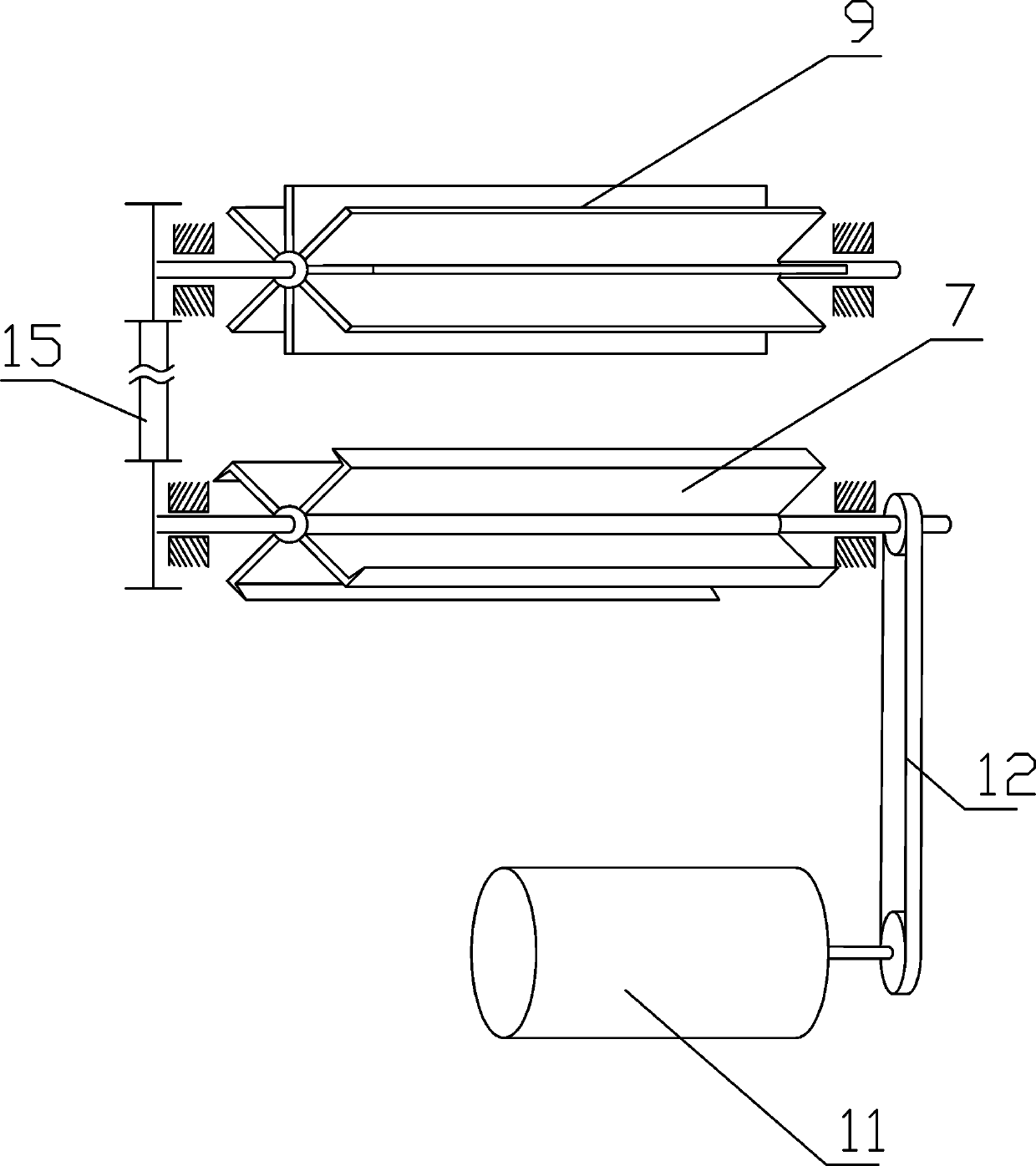

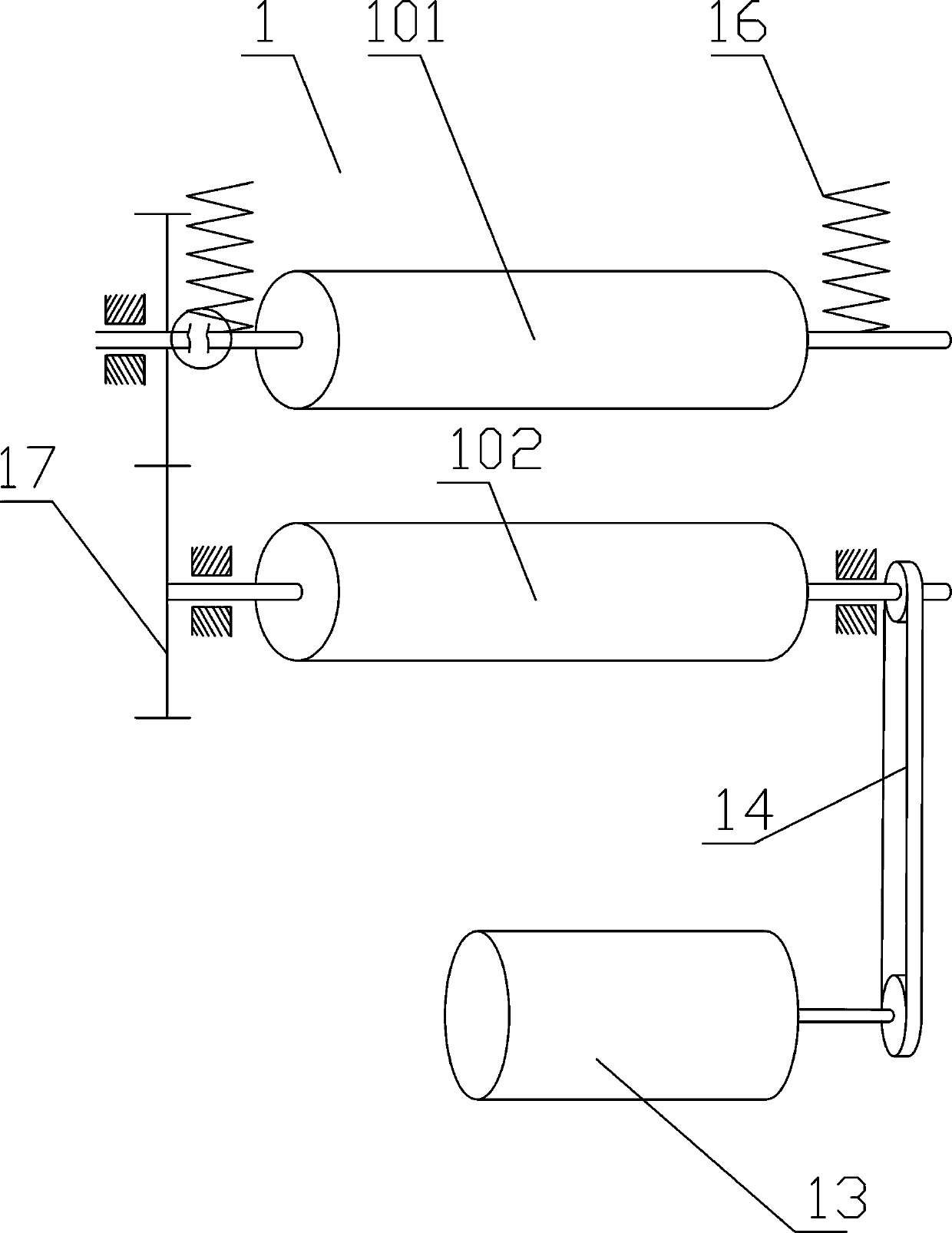

[0032] Such as figure 1 , 5 Among them, a thresher includes a first roller set 1, a second roller set 2 and a third roller set 3, and the first roller set 1, the second roller set 2 and the third roller set 3 are rotatably mounted on On the frame, it is preferably supported on the frame by bearings.

[0033] A screen 4 is provided between the first roller group 1 and the second roller group 2. The screen 4 is a replaceable structure, corresponding to grains such as rice, wheat and rapeseed respectively, and a first discharge hopper is provided below the screen 4. 6. Used to collect falling crop particles;

[0034] Between the second roller group 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com