Omni-directional movable automatic ball picking and ball dribbling assistant training robot

An omnidirectional mobile, robotic technology, applied in the direction of balls, sports accessories, etc., can solve the problem of high repetition, and achieve the effect of high mechanical efficiency, simple and compact structure, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

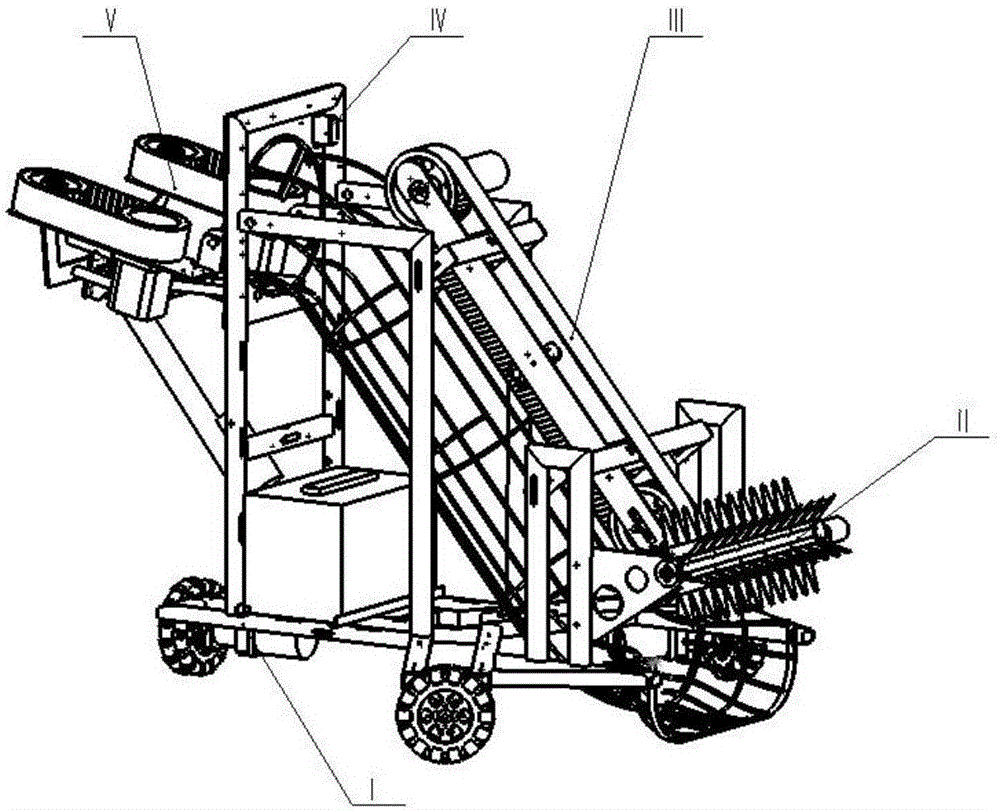

[0022] figure 1 It is the overall structure diagram of the all-round mobile automatic ball picking and dribbling robot of the present invention. The whole automatic ball picking and dribbling auxiliary training robot consists of five parts: the omnidirectional mobile chassis I, the ball receiving mechanism II, the ball dribbling mechanism III, and the ball blocking mechanism IV and ball body V.

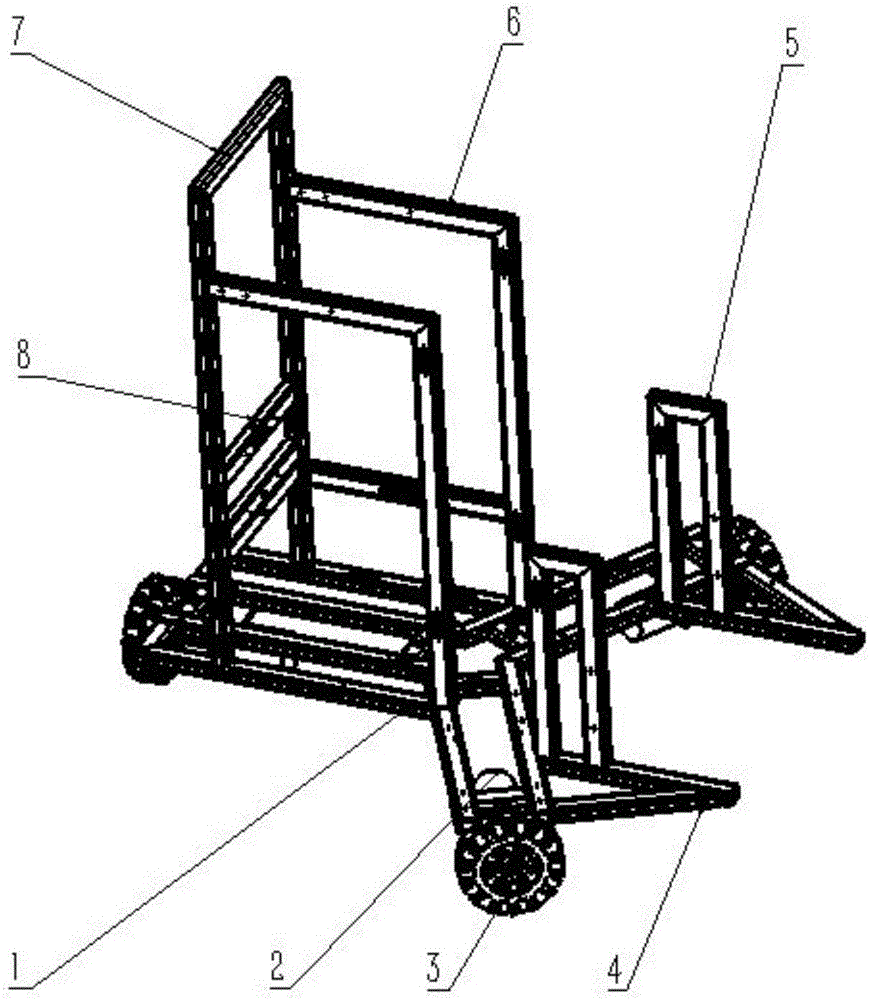

[0023] The omnidirectional chassis (structure such as figure 2 ) can translate in the plane, rotate in situ, turn with different turning radii, and walk obliquely. The chassis support of the robot is welded by a plurality of square steel pipes. The base 1 is three branches at 120° to each other. Square tubes for connecting other functional modules are welded on the base 1 to form the chassis support. Three omnidirectional wheels 3 driven by the motor 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com