A backwash lubricating oil filter

A filter and lubricating oil washing technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of increasing energy consumption, increasing the space occupied by equipment, harsh flow noise, etc., and achieve reduction Fluctuation of oil pressure and oil quantity, reduction of secondary flow and pressure pulsation, effect of reduction of lubricating oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

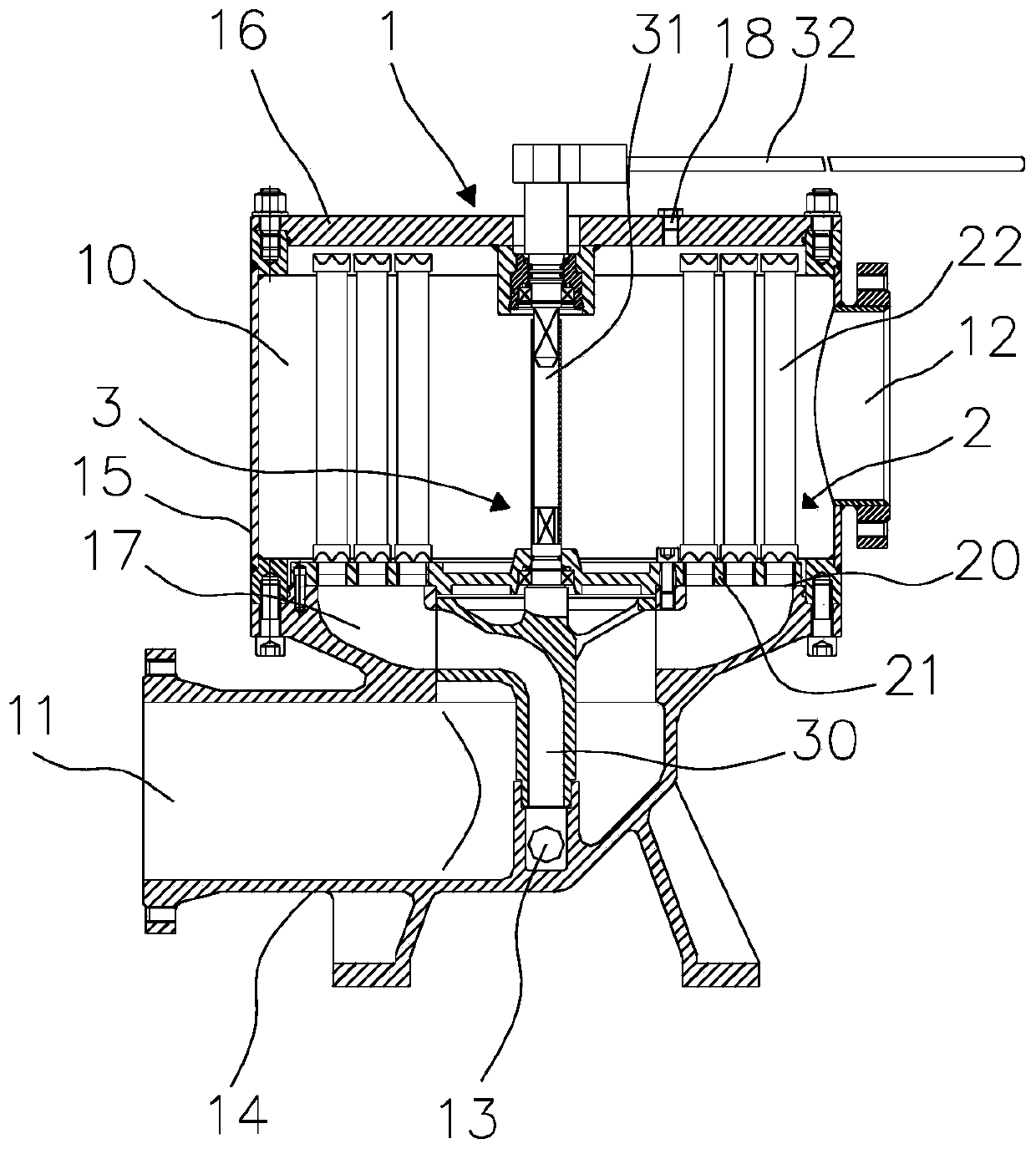

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

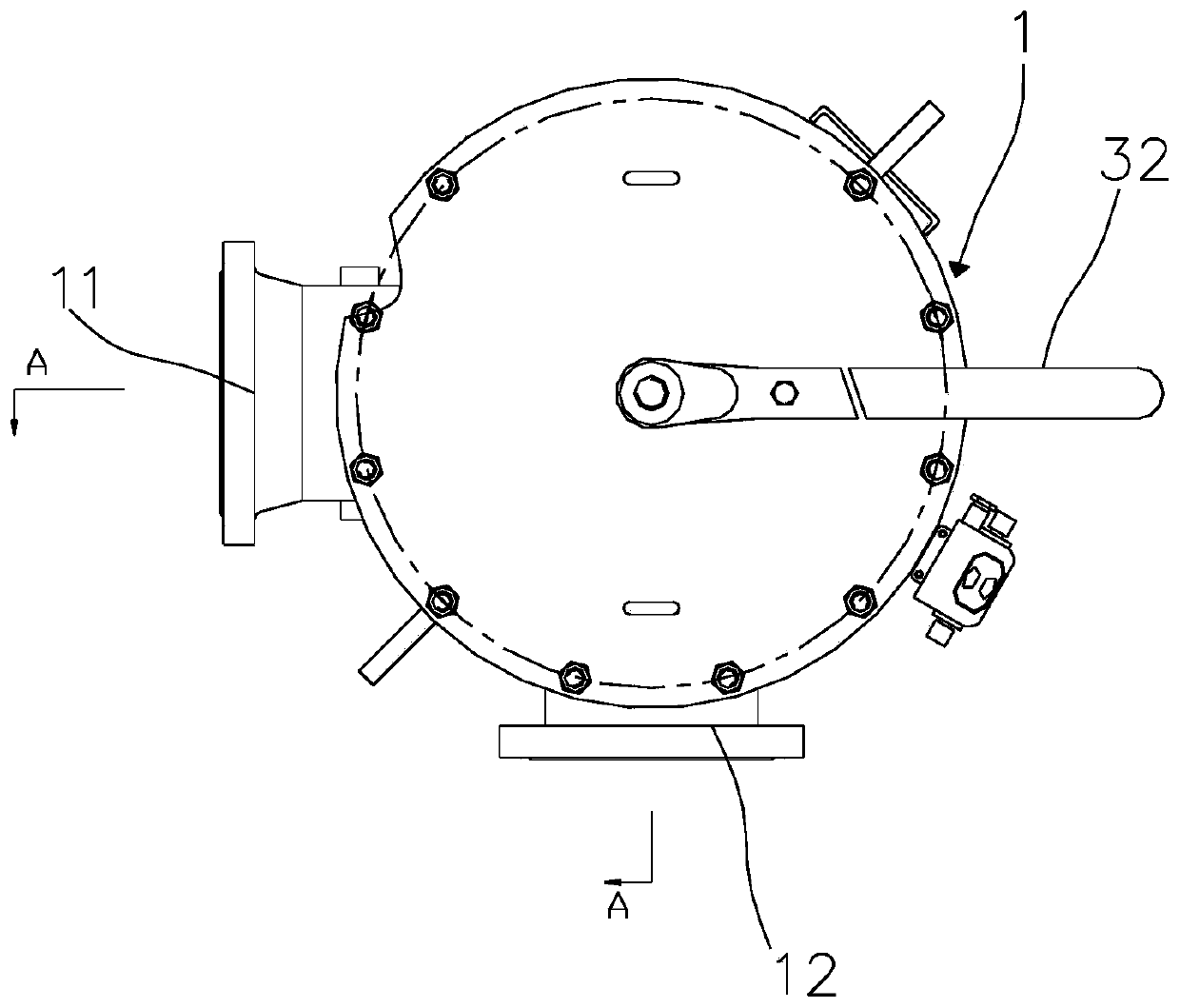

[0031] see figure 1 As shown, the embodiment of the present invention provides a backwash lubricating oil filter, comprising:

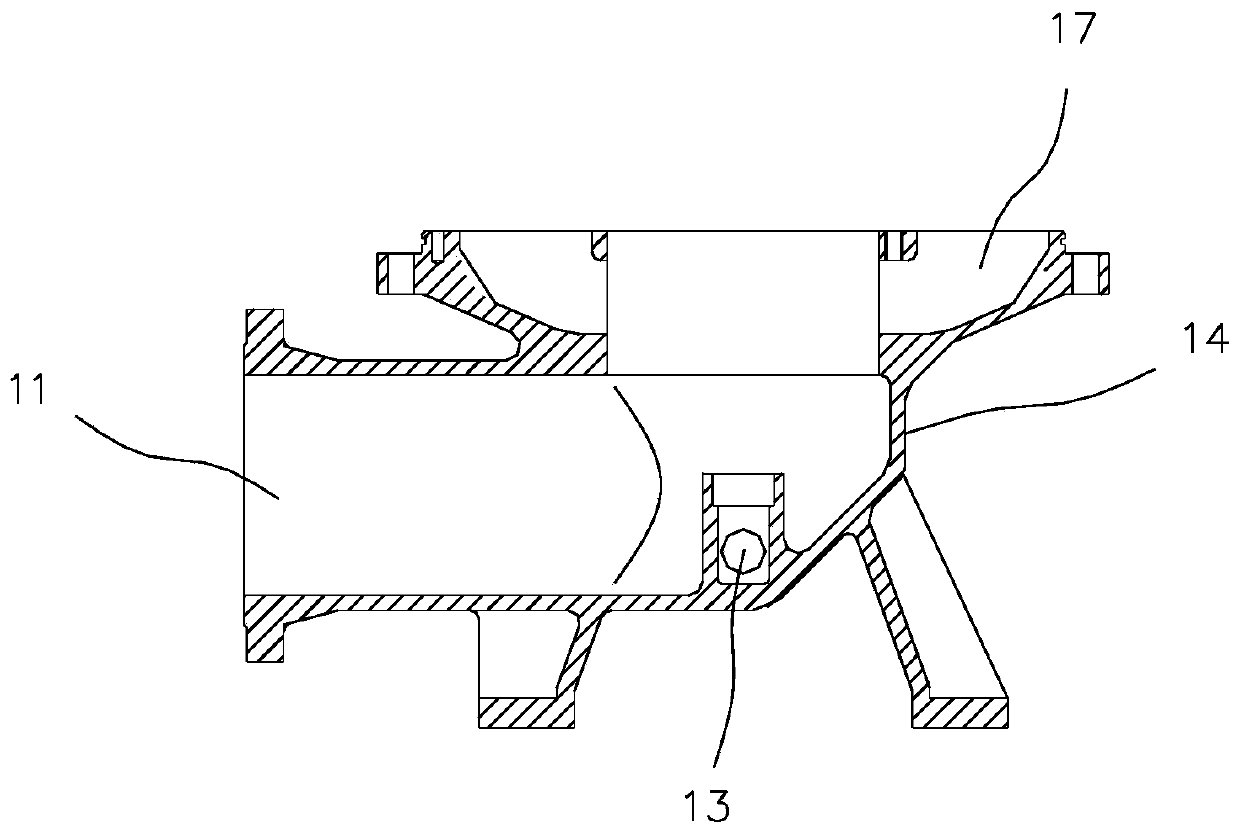

[0032] The filter body 1, the filter body 1 includes a base 14, a cylindrical housing 15 and an upper cover 16, the base 14 and the upper cover 16 respectively cover the upper and lower ends of the housing 15 to form a filter chamber 10, the base The side wall of 14 is provided with an inlet channel 11, the side wall of the housing 15 is provided with an outlet channel 12, and the bottom of the base 14 is provided with a sewage outlet 13, and the inlet channel 11, the outlet channel 12 and the sewage outlet 13 are connected with the filter chamber 10 respectively; The upper cover 16 is provided with an air release port 18 , and the air release port 18 communicates with the filter chamber 10 . Both the blowdown port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com