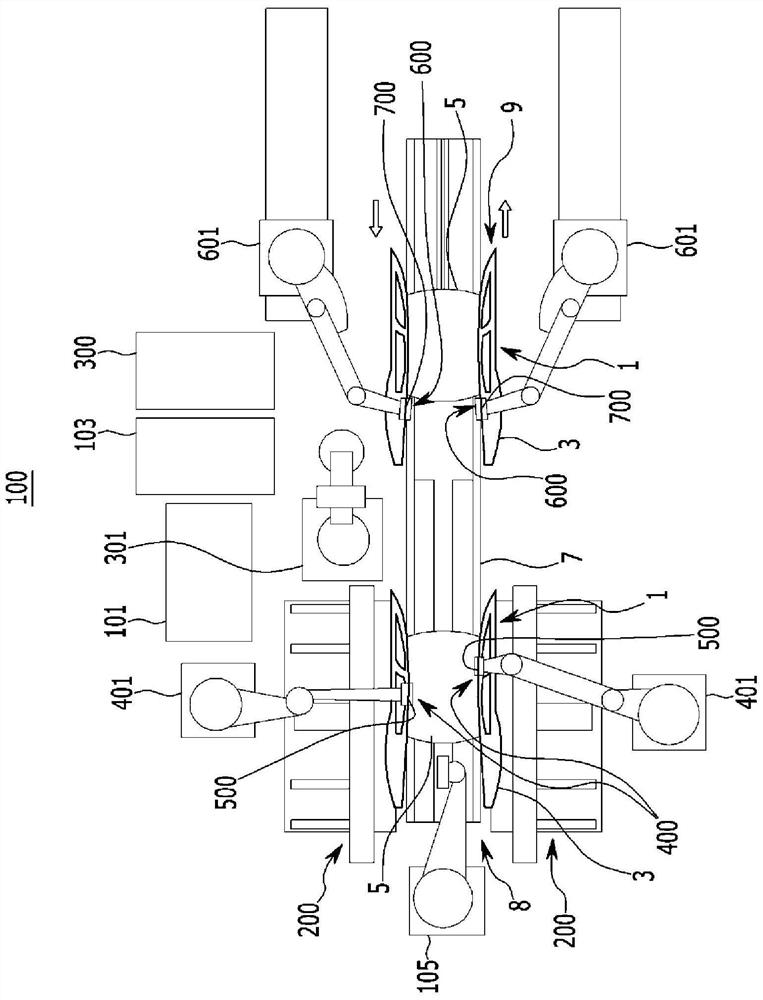

Side plate in-situ positioning fixture for ceiling laser brazing system

A technology for positioning fixtures and side panels, applied to laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increased material costs and labor costs, and poor appearance, so as to reduce equipment-preparation time and improve the appearance of the car body , Improve the effect of brazing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

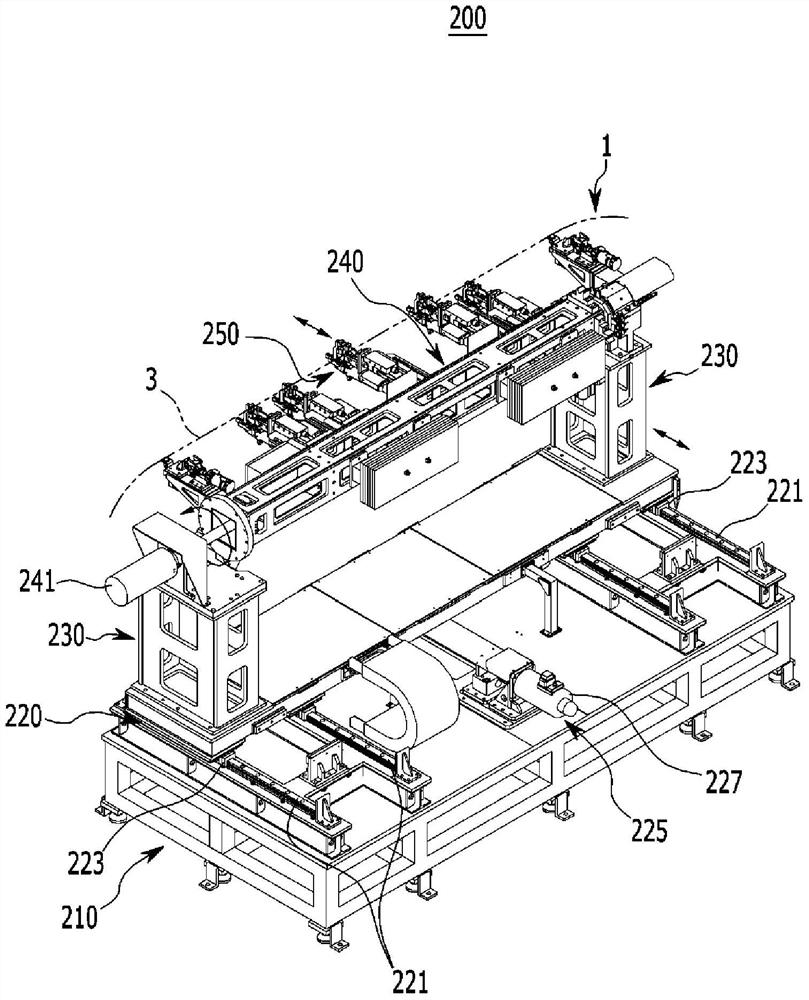

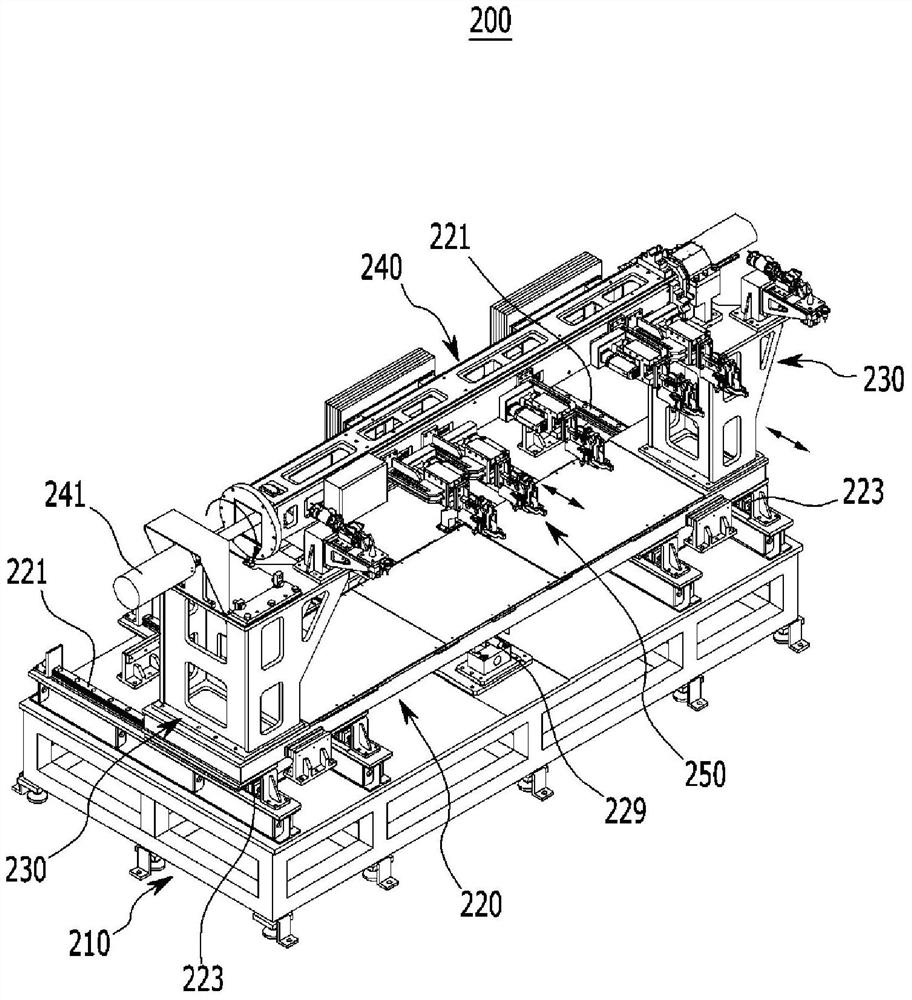

[0094] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings, in which embodiments of the present invention are illustrated. Those skilled in the art will appreciate that various changes can be made in these embodiments without departing from the spirit of the invention.

[0095] Accordingly, the drawings and description are to be regarded as illustrative in nature and not restrictive. In the specification, the same or equivalent reference numerals refer to the same or equivalent components.

[0096] In the drawings, the size and thickness of each configuration are arbitrarily shown for understanding and convenience of expression, but the present invention is not limited thereto, and the thicknesses of layers, films, plates, regions, etc. may be exaggerated for clarity in the drawings.

[0097] In the following description, the distinction of component names by "first", "second", etc. is to distinguish based on the same com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com