Pneumatic wrench semi-automation device

A semi-automated wrench technology, applied in the direction of portable mobile devices, motor tools, manufacturing tools, etc., can solve the problems of difficult production and manufacturing, large assembly quantity, inconvenient manual operation, etc., and achieve easy operation, improved assembly quality, and saving The effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

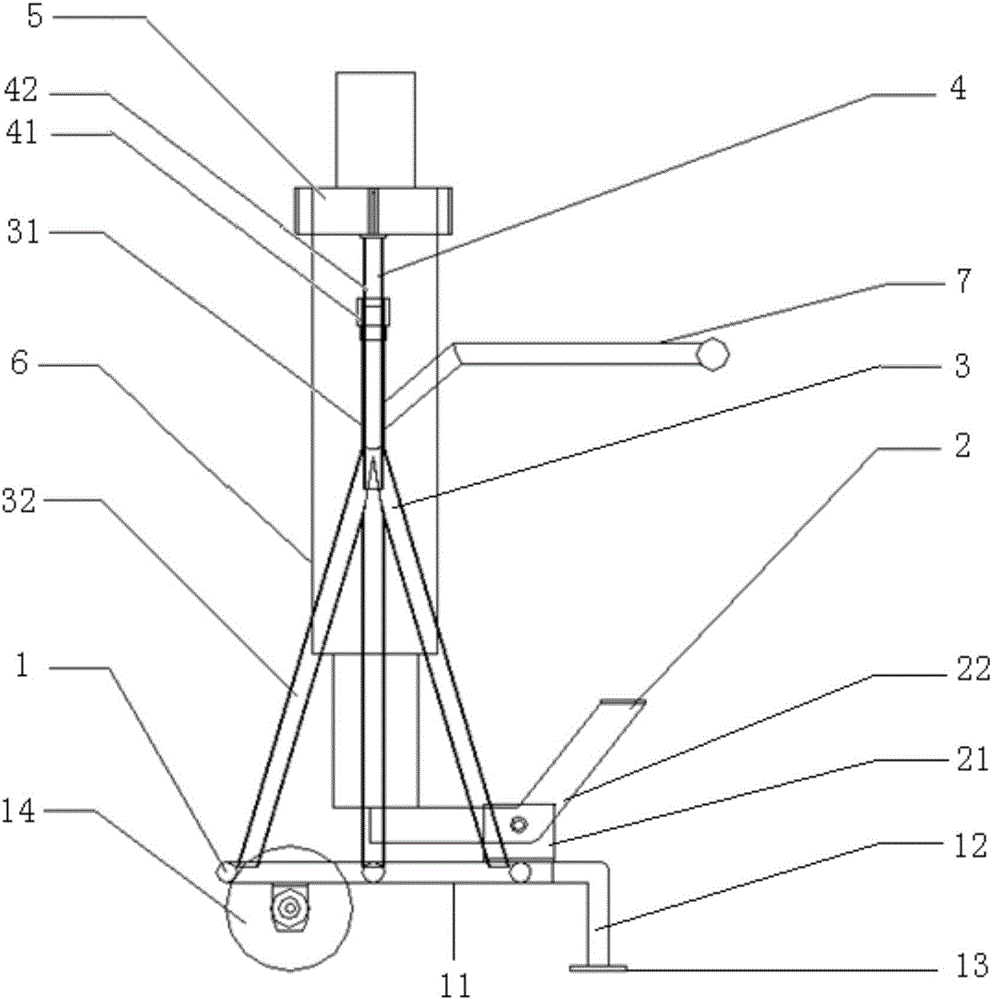

[0014] Such as figure 1 As shown, the pneumatic wrench semi-automatic device of the present invention includes a support base 1, a pedal drive frame 2, two fixed supports 3, two movable supports 4, an annular fixed seat 5 and a pneumatic wrench 6;

[0015] One end of the top of the support base 1 is movably connected to the pedal drive frame 2, and two fixed supports 3 are arranged in parallel on both sides of the top of the support base 1, and the top of each fixed support 3 is fixedly connected to the ring-shaped fixed seat 5 through a movable support 4, and the wind-driven The upper part of the wrench 6 passes through the annular fixing seat 5 and is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com