A control system for an electric injection molding machine

A control system and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as high maintenance costs, lack of universal interfaces, and long time consumption, and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the drawings and specific embodiments.

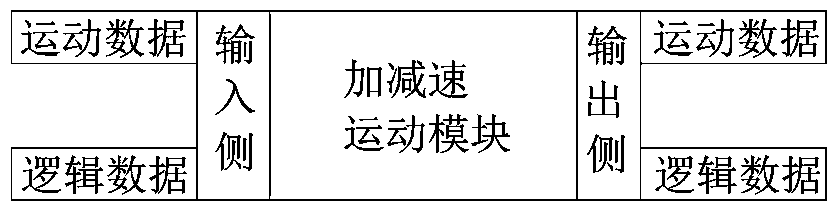

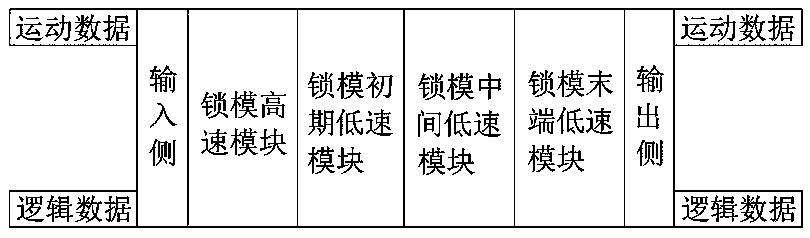

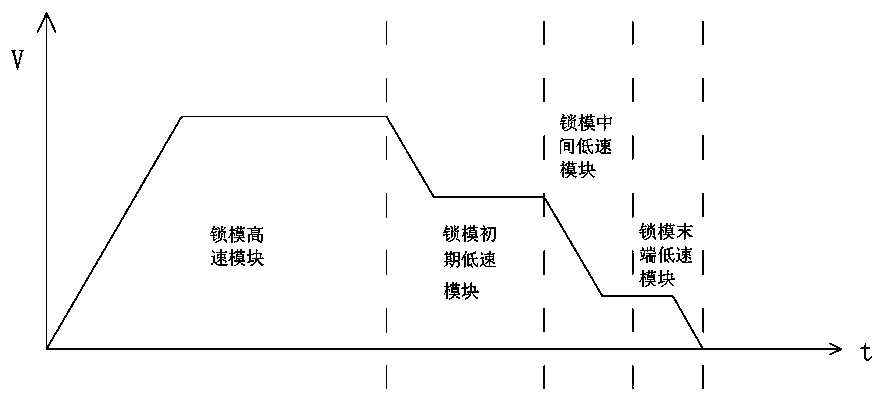

[0062] The invention discloses a control system for an electric injection molding machine, which includes a mold locking function module, an injection function module, a pressure holding function module, a glue pumping function module, a metering function module, a mold opening function module, a jacking function module and a jacking function module The module has a total of eight functional modules, each of which is provided with a common interface, and the eight functional modules are connected in series through the common interface, and the connection sequence of the eight functional modules can be arranged and selected arbitrarily. That is, the eight functional modules can be connected in any order, and the user can connect each functional module in series according to the required ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com