Method for quickly printing microstrip pieces

A microstrip film, fast technology, applied in the direction of printing, printing devices, etc., can solve the problems of affecting the coating rate of conductive adhesive, poor consistency of conductive adhesive, and slow rate of microstrip film application, so as to improve the rate of application of adhesive Efficiency, simple method, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

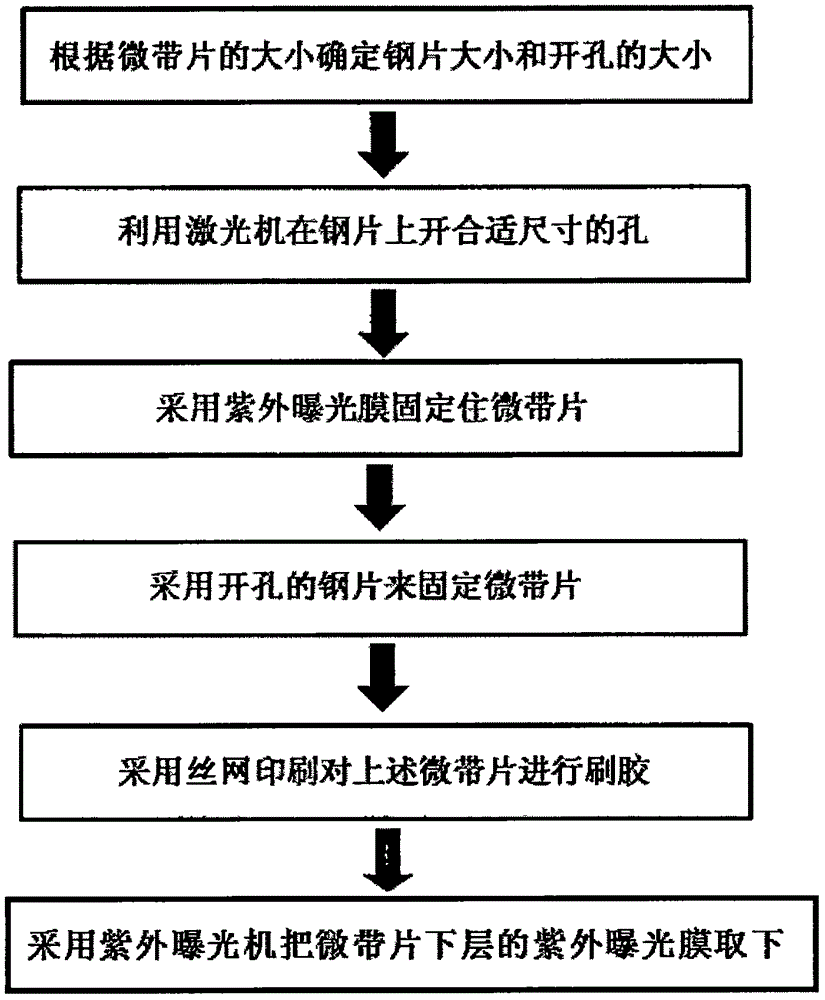

[0024] A kind of method for fast printing microstrip sheet provided by the invention comprises the following steps:

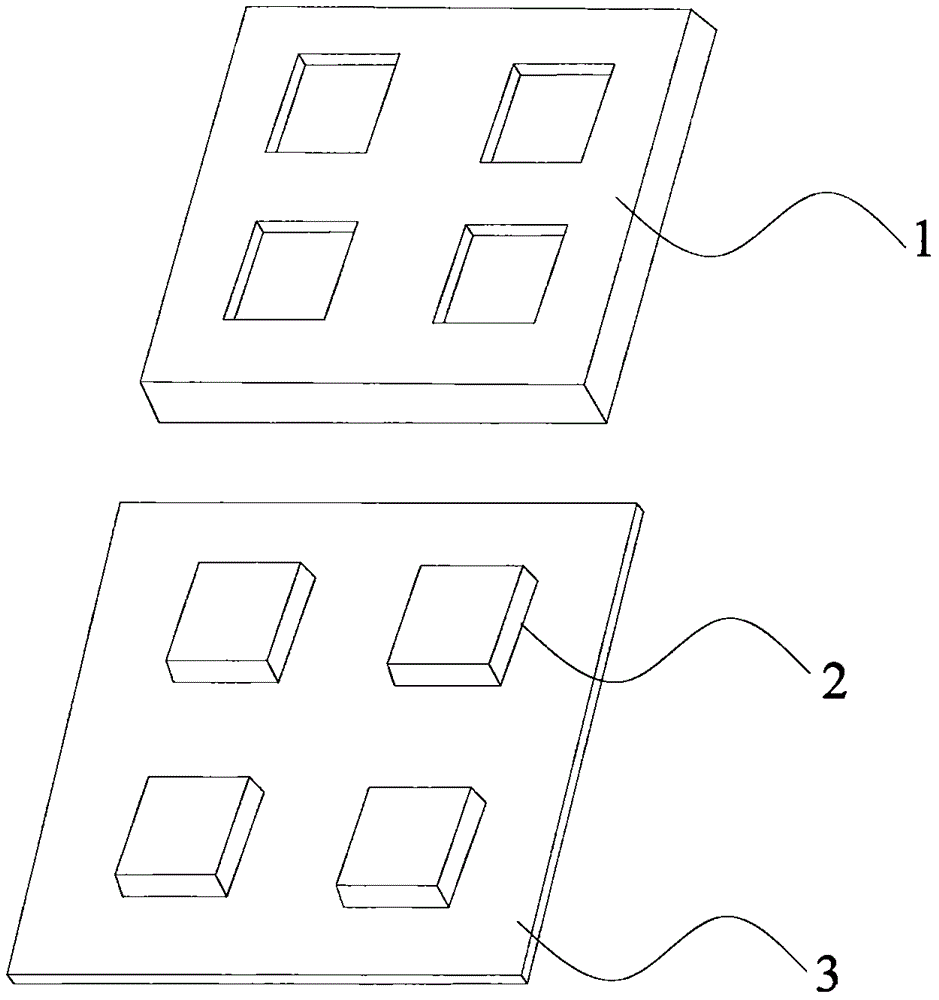

[0025] Step 1. Determine the size of the steel sheet and the size of the opening in the steel sheet according to the number of microstrip sheets to be printed at one time and the size of the microstrip sheet. Determine the thickness of the steel sheet and prepare the required steel sheet according to the thickness of the microstrip sheet. piece;

[0026] Step 2. Use a laser machine with a hole opening power of 10w to punch a through hole on the steel sheet that is the same size as the microstrip sheet;

[0027] Step 3: Use UV exposure film to fix the microstrip sheet to be printed, and the distance between the microstrip sheet on the blue film should be the same as the distance between the through holes of the steel sheet;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com