A ground automatic phase separation device and its control method

An automatic phase separation and grounding technology, which is applied in the direction of transportation and packaging, power lines, vehicle parts, etc., can solve the problems of inability to accurately determine the thyristor turn-off point, long dead zone of power failure in the neutral zone, and low service life of mechanical switches. Achieve high economy and practicability, improve service life and perfect protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

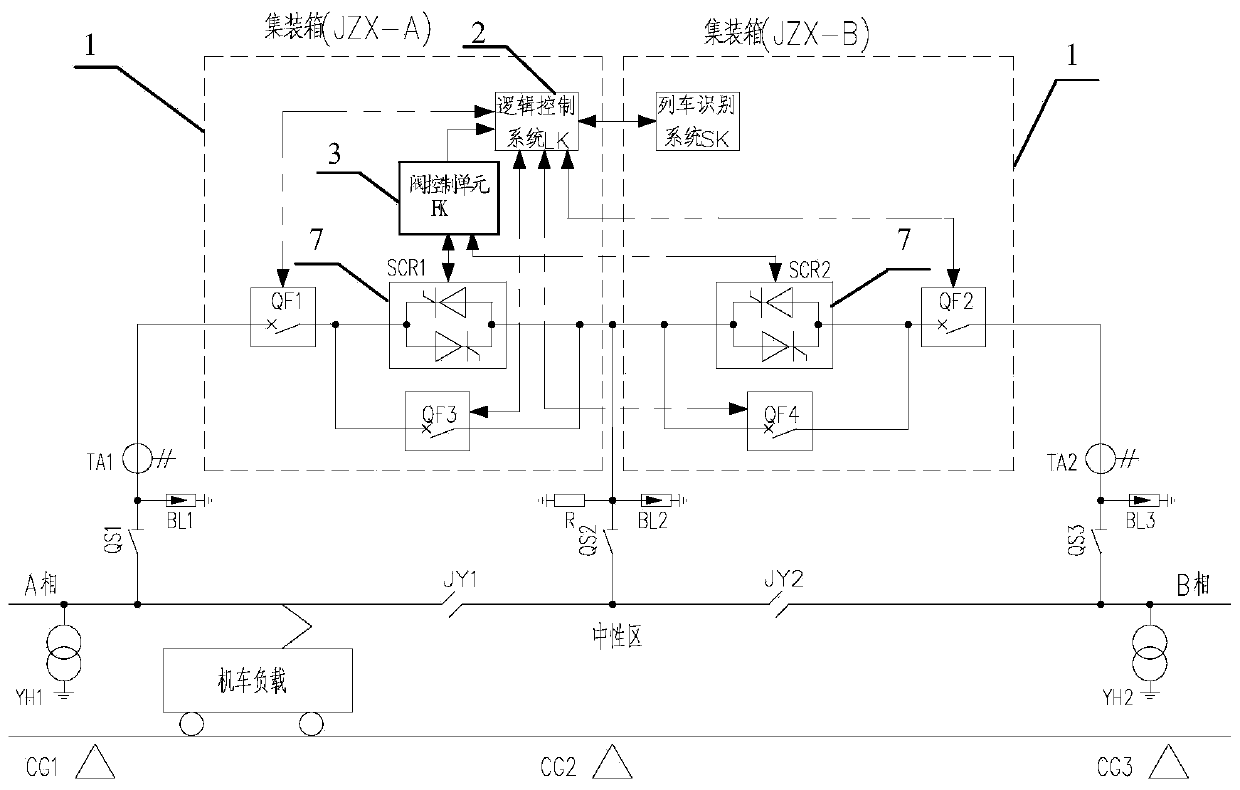

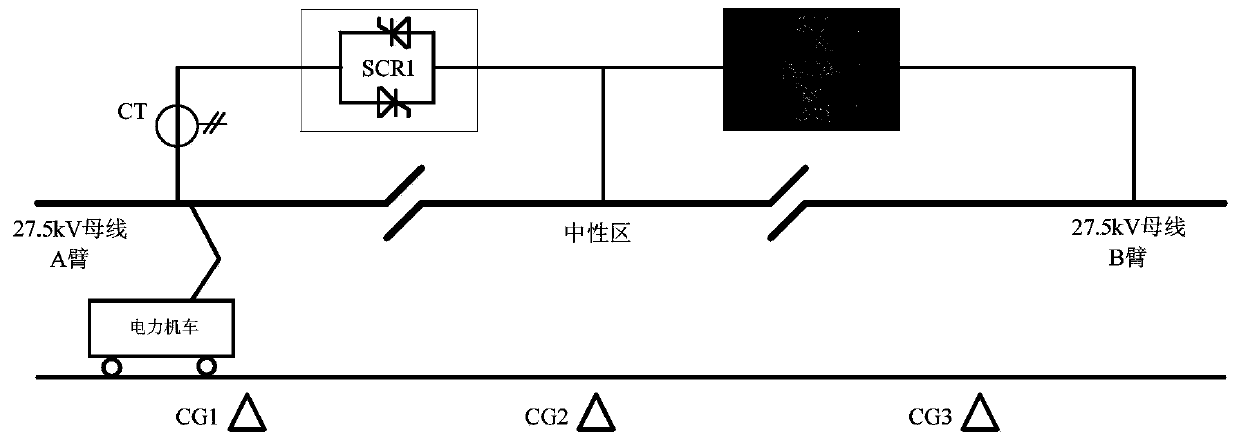

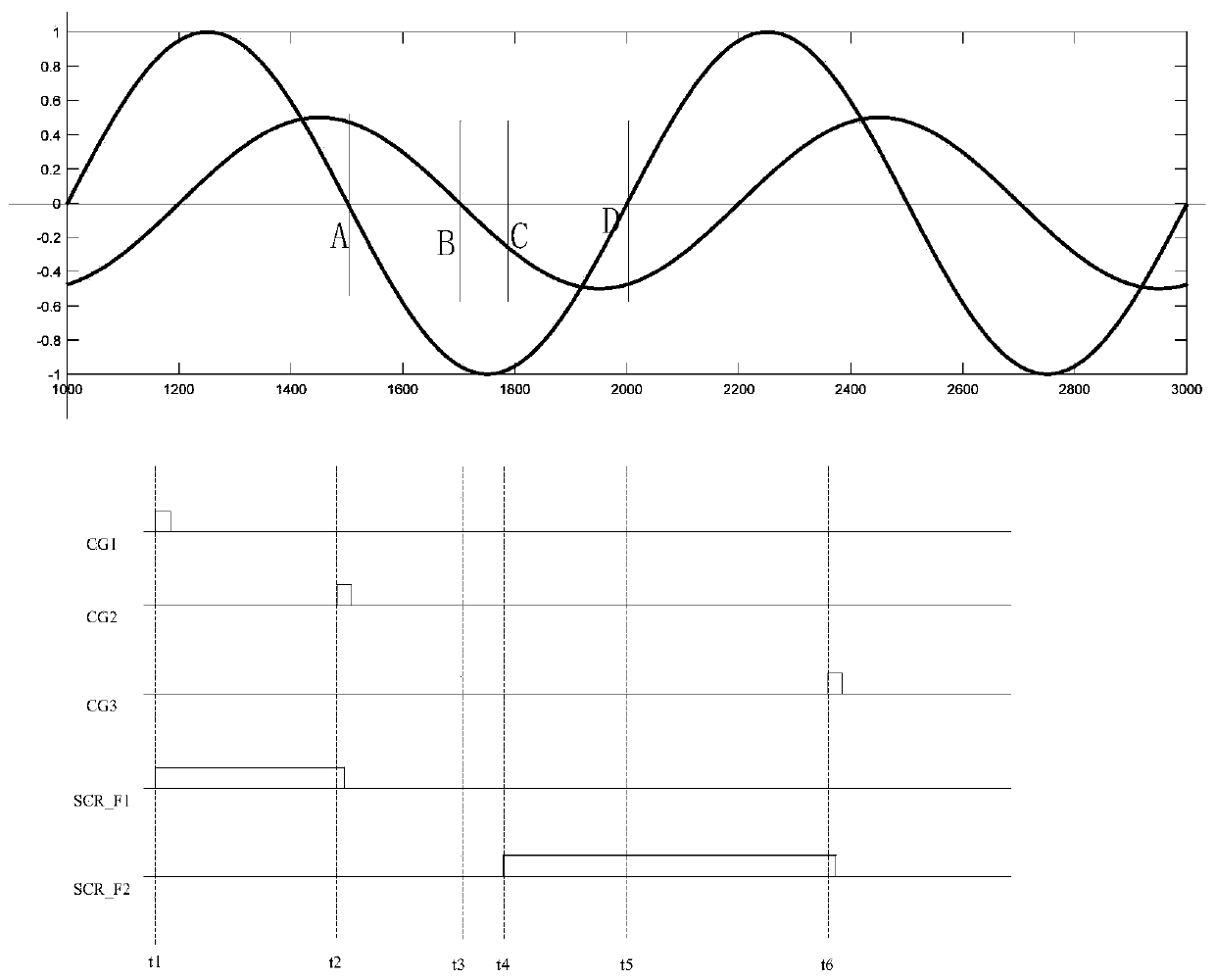

[0035] like figure 1As shown in the figure, the ground automatic phase separation device in this embodiment includes a train identification unit for identifying the running position and direction of the train, a logic control system 2 (LK), a valve control unit 3, and two thyristor valve groups 7 (SCR1, SCR2) The thyristor valve group unit formed in series and the current detection unit for detecting the current of the thyristor valve group 7, the thyristor valve group unit is respectively connected with the two-phase (A, B-phase) power supply arm of the catenary and the neutral area, and the logic control system 2 is based on The train running position and direction identified by the train identification unit are connected to a thyristor valve group 7 to supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com