Detection circuit for pressure sensor of aeroengine

A pressure sensor and aero-engine technology, which is applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problem of damage to the power supply circuit of the pressure sensor, and achieve the effects of perfect protection and detection functions, high test accuracy, and small ripples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

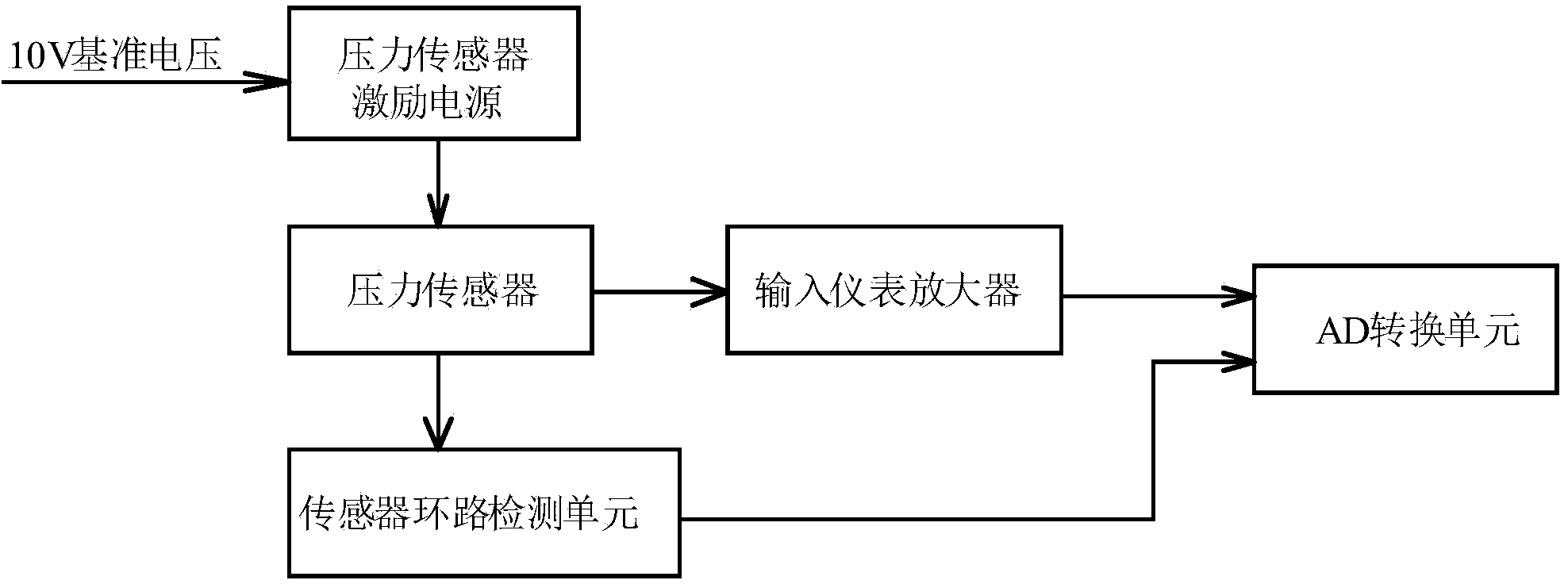

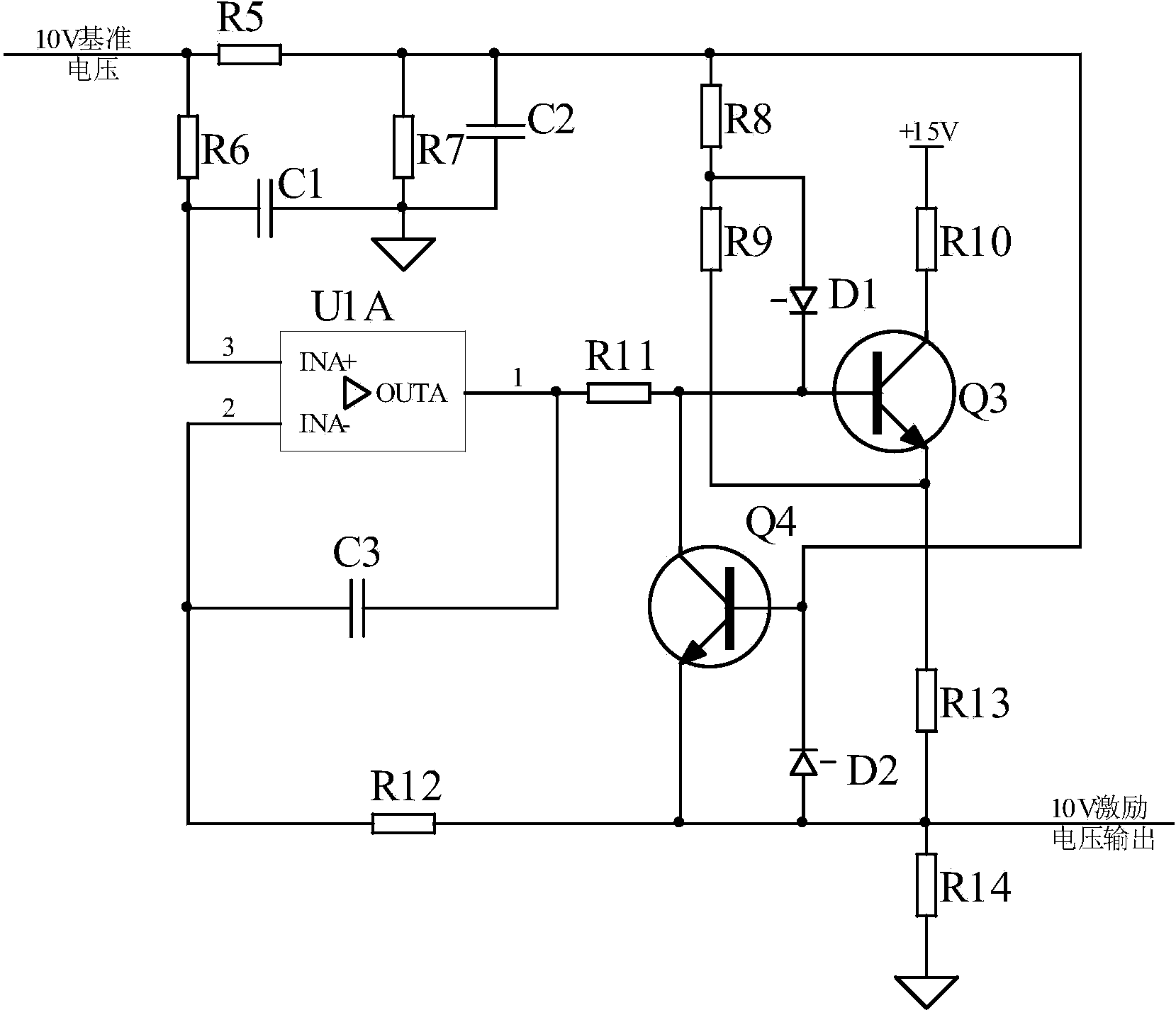

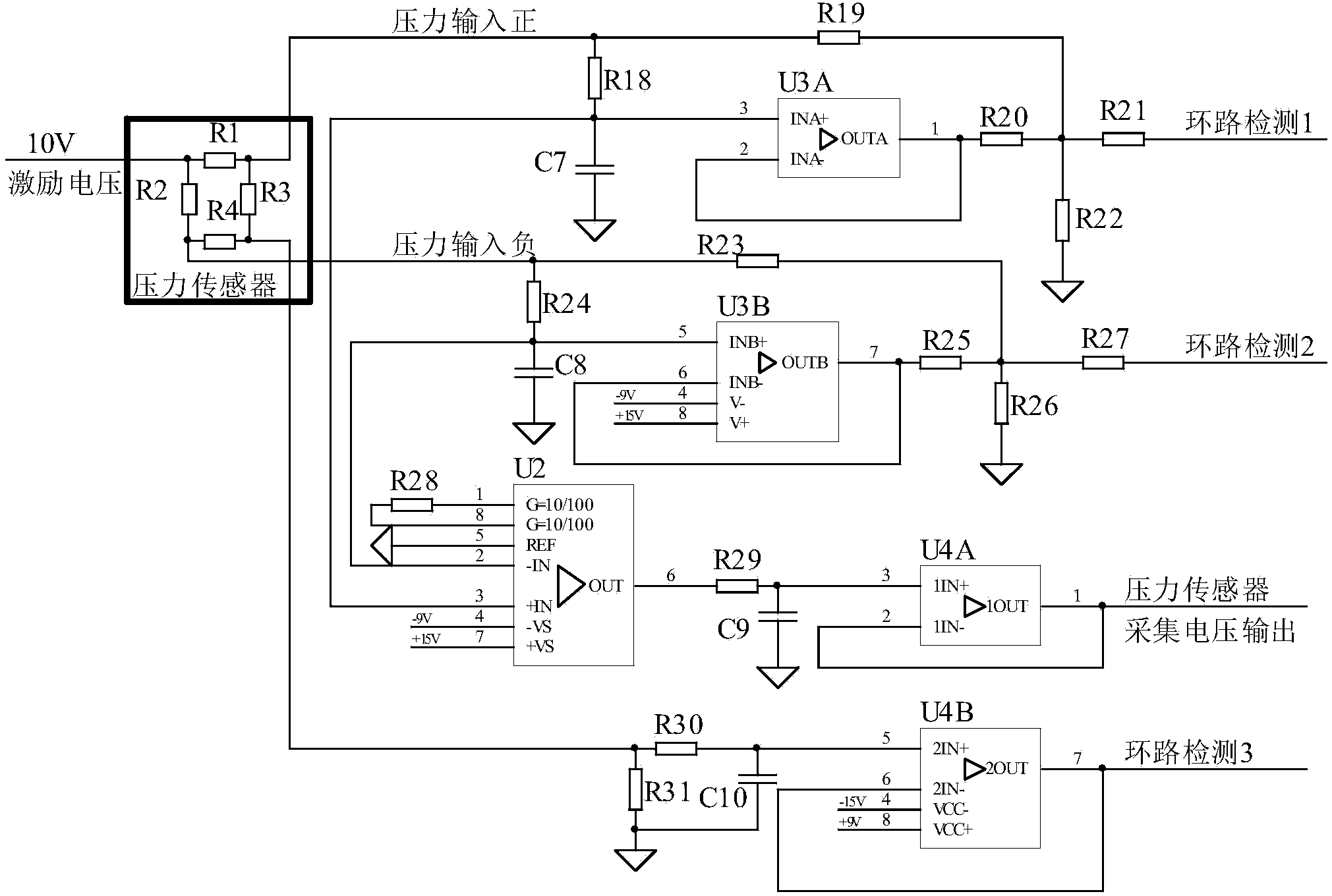

[0019] refer to figure 1 , figure 2 . The aeroengine pressure sensor is a Huygens balanced bridge composed of strain resistances, and its detection circuit mainly includes a pressure sensor excitation power supply, a pressure sensor loop detection unit and a pressure sensor input instrument amplifier. The excitation power supply is electrically connected to the triode Q4 and transistor Q3 connected in parallel between the integrating capacitor C3 between the inverting input terminal and the output terminal of the comparative amplifier U1A and the current limiting resistor R11 at the output terminal. Q3, constitutes the reference voltage excitation output shutdown current limiting protection circuit; the excitation power supply is electrically connected to the pressure sensor, and the pressure sensor is electrically connected to the AD conversion unit through the sensor loop detection unit and the input instrument amplifier; the pressure sensor Wheatstone bridge four detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com