Laver drying and transporting trolley

A technology for transporting trolleys and seaweed, which is applied in the directions of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of time-consuming and laborious, inconsistent drying time, and inconvenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

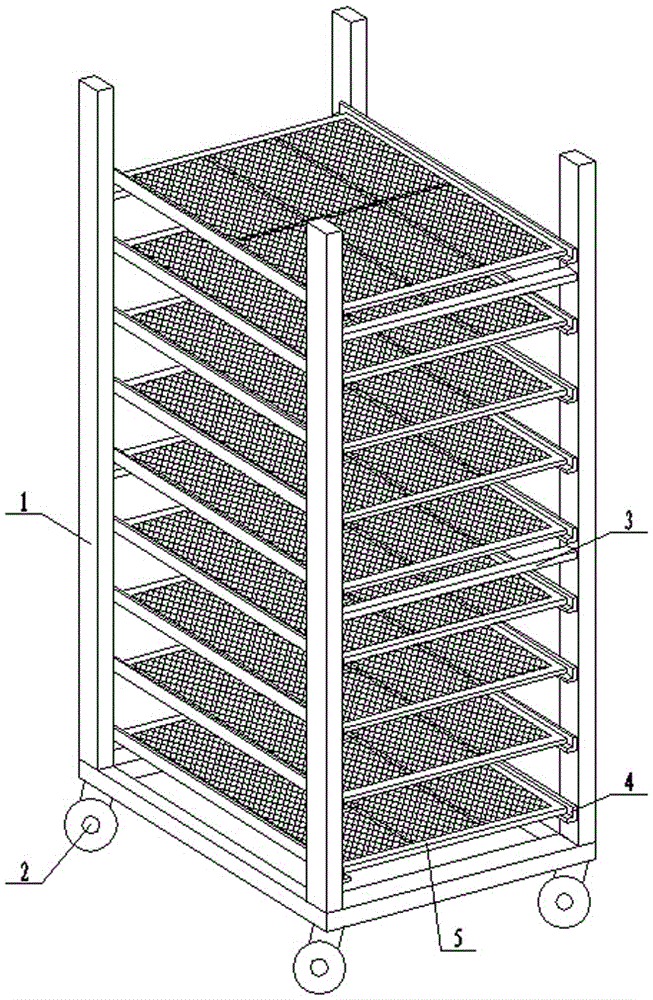

[0010] Such as figure 1 , figure 2 As shown, the laver drying and transporting trolley includes: a frame 1, the frame 1 is set on the ground by rollers 2, and transverse reinforcing ribs 3 are respectively arranged at the middle and upper ends of the frame 1. Several groups of L-shaped longitudinal slide rails 4 are evenly arranged on both sides of the inside of the frame 1, and a grid drying carriage 5 is slidably arranged between each group of L-shaped longitudinal slide rails 4, and the grid drying carriage 5 5 structures including: square

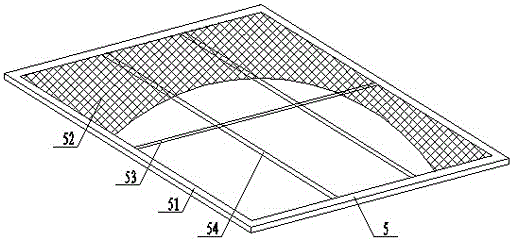

[0011] The carriage body 51 is provided with a drying screen 52 at the inner upper end of the square carriage body 51, and a horizontal support rod 53 and two cross support rods 53 and two Root vertical support rod 54.

[0012] When the above-mentioned laver drying transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com