Drying machine for corrugated boards

A corrugated cardboard and dryer technology, applied in dryers, drying, mechanical processing/deformation, etc., can solve the problems of different drying time, affecting production efficiency, etc., to achieve consistent drying time and production efficiency. The effect of stable efficiency and avoiding the reduction of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

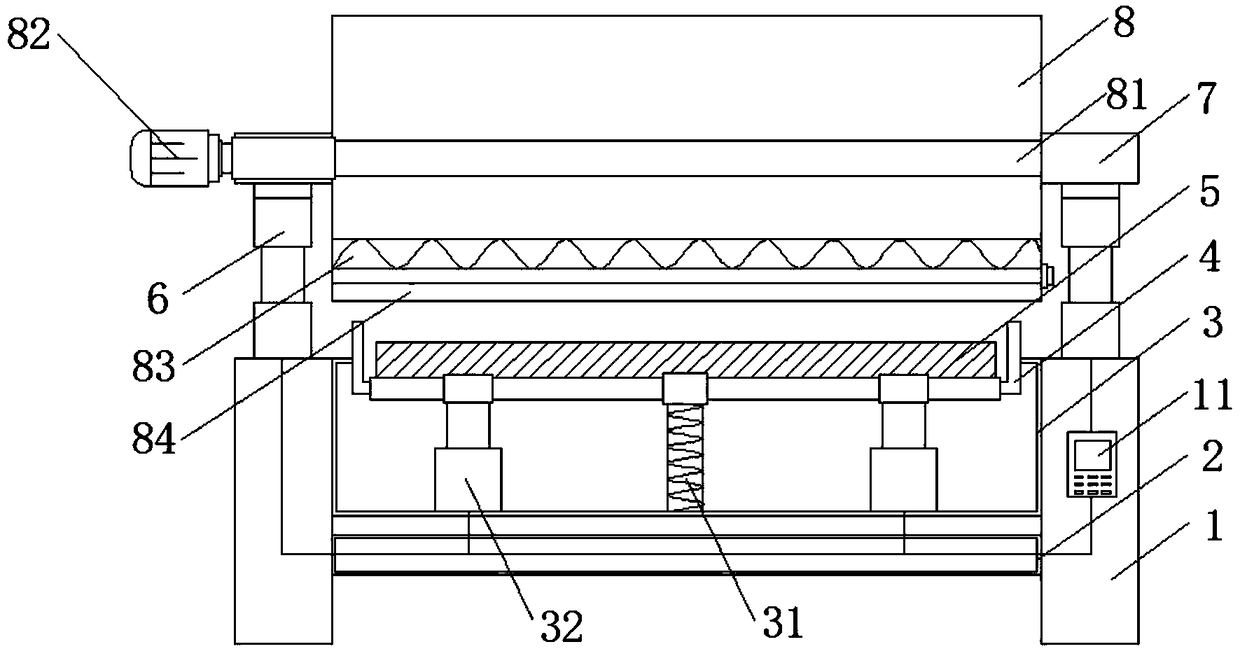

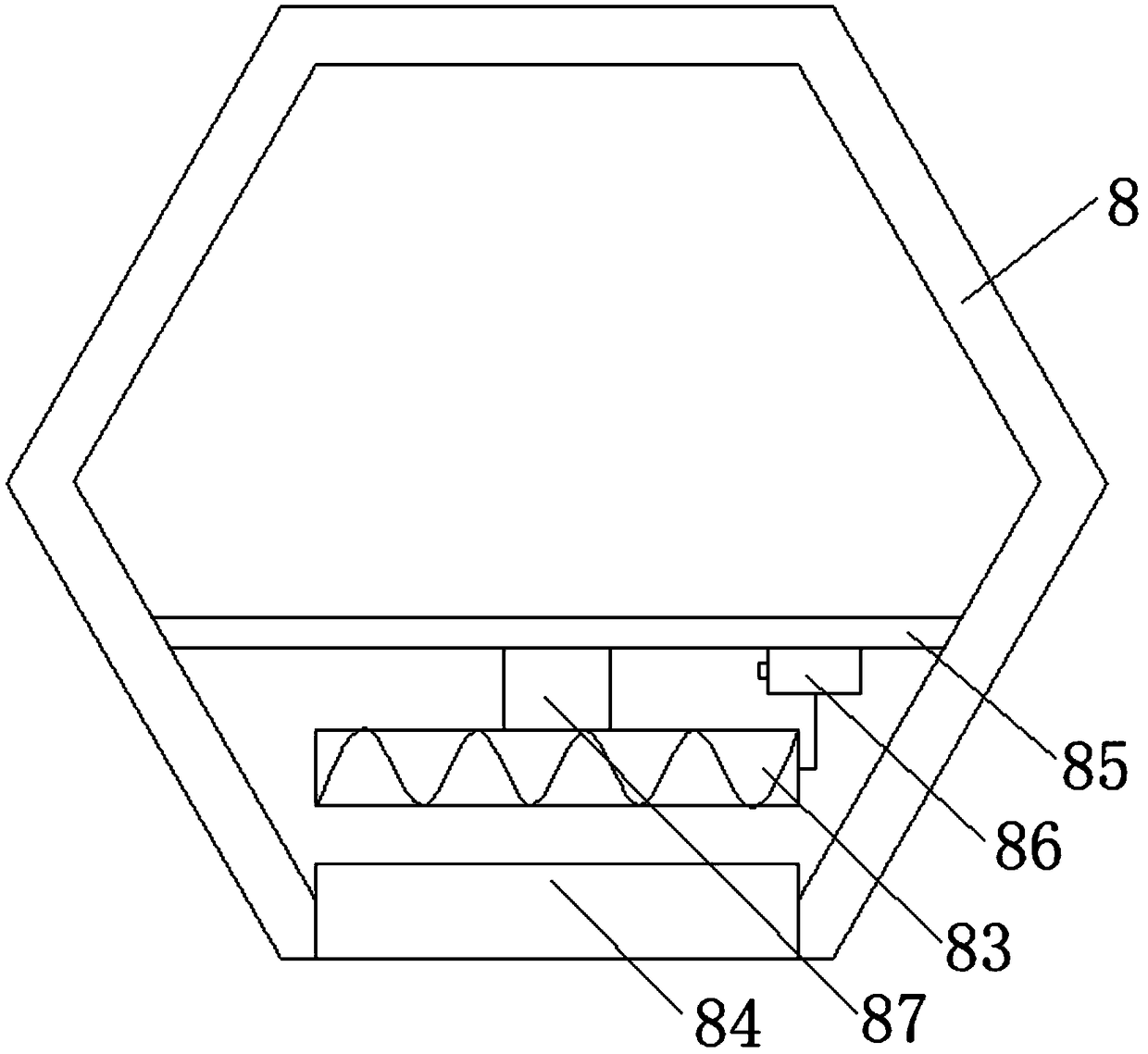

[0019] Such as figure 1 A dryer for corrugated cardboard is shown, which includes a machine body. The machine body is provided with a workbench 5 for placing corrugated cardboard and a heating cylinder 8 for providing heat. The heating cylinder 8 is located on the top of the workbench 5 .

[0020] In order to solve the problem that existing dryers have different efficiency when drying corrugated cardboard with different thicknesses, the body includes two supporting columns 1 and a connecting plate 2 connecting the two supporting columns 1, and the top of the supporting column 1 is provided with a first The electric telescopic rod 6, the top of the first electric telescopic rod 6 is provided with a fixed plate 7, and the end of the heating cylinder 8 is connected with the fixed plate 7.

[0021] In this embodiment, by setting two support columns 1 and connecting plates 2 connecting the two support columns 1, a first electric telescopic rod 6 is arranged on the top of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com