Novel closed sludge drying machine

A sludge drying and closed technology, which is applied in the field of drying machines, can solve the problems of large drying time difference of sludge transfer unit, uneven heat supply of upper and lower layers of air supply, large heat difference of air supply, etc., to achieve sludge The drying time is the same, the drying effect is improved, and the heat is equalized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

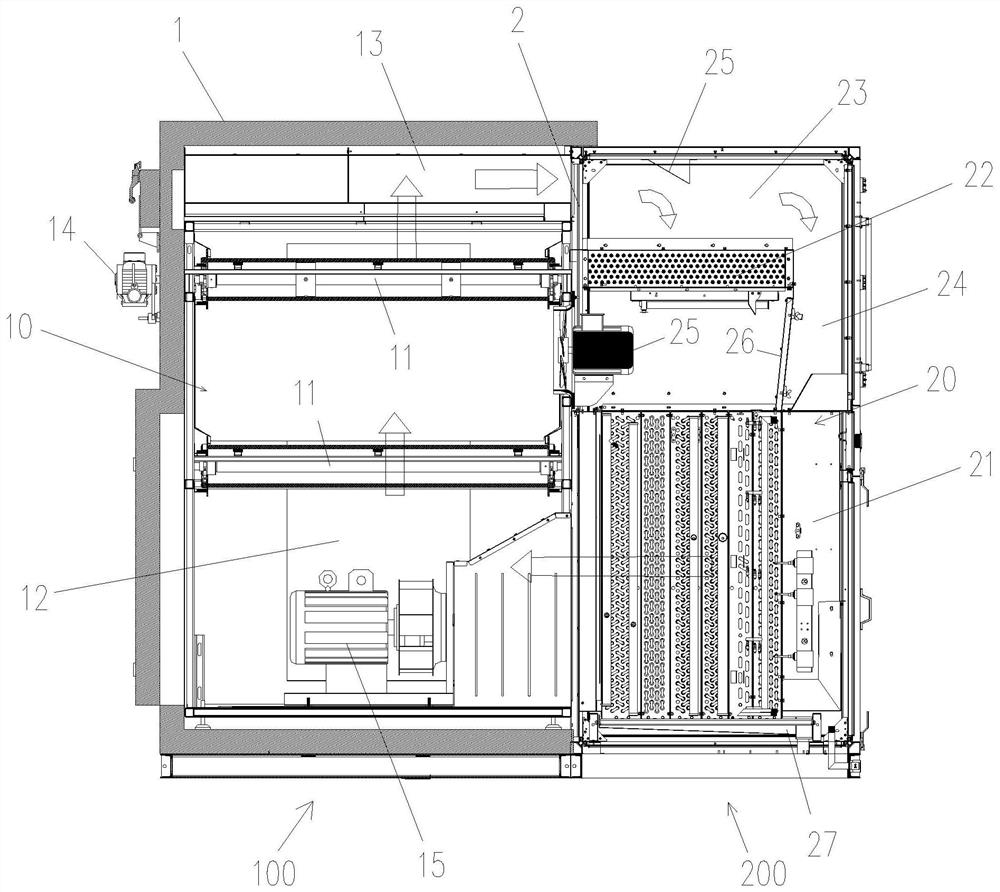

[0042] Please refer to the attached figure 1 As shown, the embodiment of the present invention discloses a new type of closed sludge dryer, including a heat pump assembly 200 and a drying assembly 100, and the heat pump assembly 200 includes a main system heat exchange system 21 and an auxiliary heating system 22 , the drying assembly 100 includes a sludge conveying system, the sludge conveying system includes at least two layers of sludge conveying unit 11, the heat exchange system 21 of the main system produces the first drying hot air, and the first The drying hot air passes through the sludge conveying unit 11 in turn to heat and dry it; the auxiliary heating system 22 produces the second drying hot air, and the second drying hot air flows into the first and subsequent sludge The first hot drying air passing through the mud conveying unit 11 is used to increase the temperature of the first hot drying air this time.

[0043] The sludge dryer is equipped with an auxiliary h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com